- How to operate color printing device of napkin tissue machine→

- How to produce napkin paper?→

![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-OQ-7000A

Model:

XY-OQ-7000A

![]() Power:

16KW 380V 50HZ 3Phase

Power:

16KW 380V 50HZ 3Phase

![]() Application:

Napkin paper production line

Application:

Napkin paper production line

![]() Weight:

About 5 tons

Weight:

About 5 tons

![]() Output:

napkin tissue paper

Output:

napkin tissue paper

![]() Packaging Dimension:

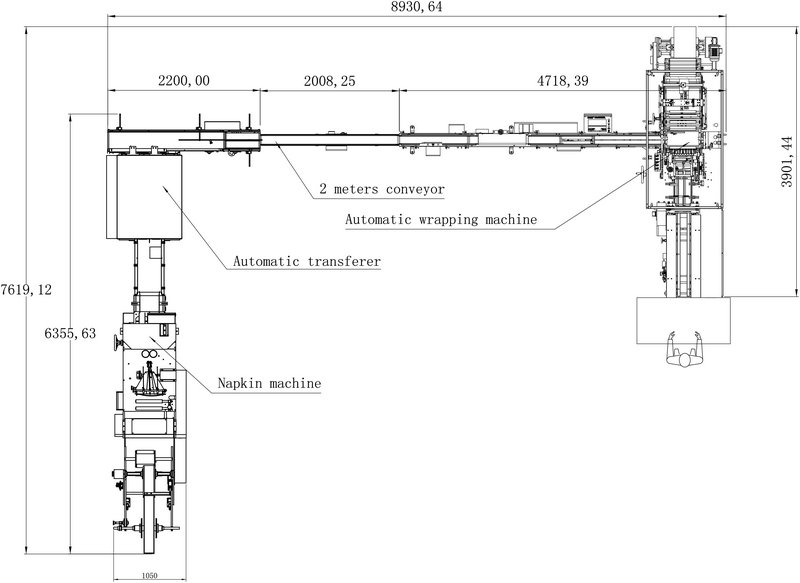

7610*8930*2100mm

Packaging Dimension:

7610*8930*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

No need hand touch napkin tissue paper machine production line

This production line including two machine:

1.XY-OQ-7000A Automatic transfer napkin paper folding machine

2.XY-BT-298 High speed napkin paper packing machine

1.XY-OQ-7000A Automatic transfer napkin paper folding machine

This industrial-grade solution delivers unmatched efficiency with its fully automated workflow, integrating:

Smart Folding: Precision-engineered creasing for uniform napkin shapes

Multi-Process Embossing: Simultaneous texture imprinting and pattern embossing

Optional Customization:

✓ Color printing for branding

✓ Glue lamination for enhanced durability

Seamless Transfer: Automated conveyor system for continuous production

2. XY-BT-298 High speed napkin paper packing machine

Technician parameter:

1. Speed: 50-60bags/min

2. Packing size (L*W*H): 165*165*100mm

3.Power: 11KW (380V 50HZ 3Phase)

4. Overall size(L*W*H): 3560*5885*1925mm

5.Weight:3000KG

6. Packing film: CPP,PE, OPP/CPP, PT/PE, and other film sealed on both sides

1. Unfolding size of napkin tissue: 300*300mm

2. Folding size of napkin tissue: 150*150mm

3. Speed: 1000 sheets/min

4. Power: 4.5KW (380V 50Hz 3Phase)

5. Raw paper: diameter 1200mm and width 300mm

6. Automatic stop when paper broken

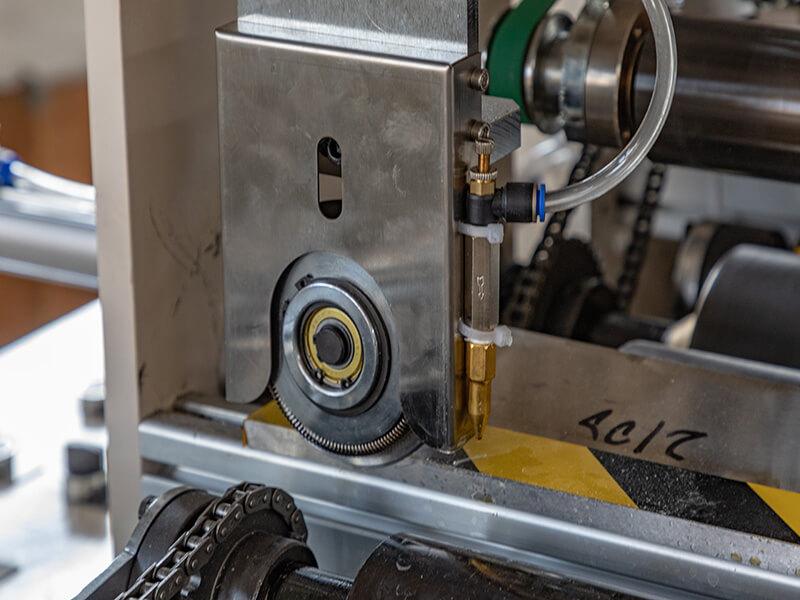

7. One set of full embossing device

8. Web guiding device

9. Layers of the paper: 1-2 layers 15 - 21 g/ m², 1 layer paper needs≥19g

10. Counting: electronic counter, pneumatic hop

11. The host structure: wallboard structure.

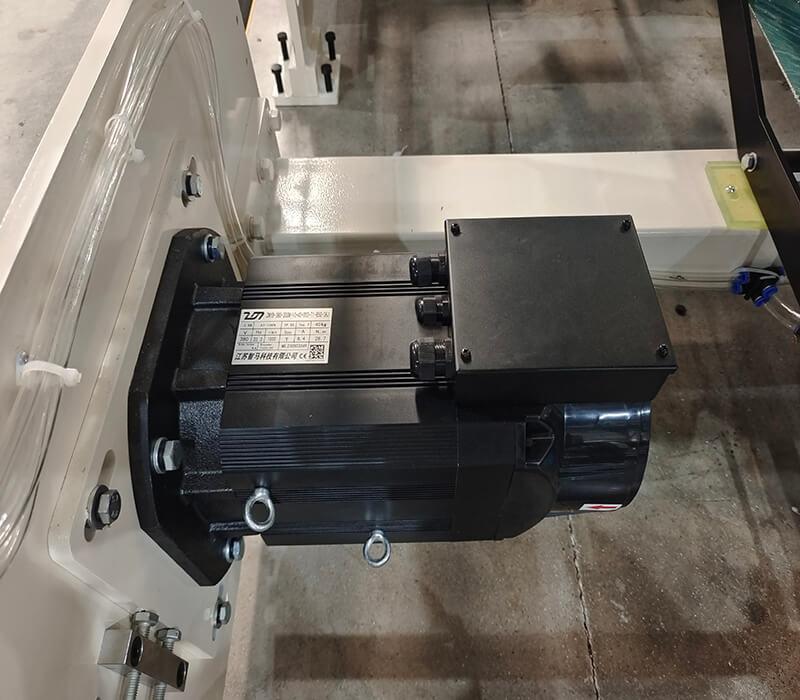

12. The host drive: synchronous toothed belt drive, a flat belt conveying.

13. The control mode: frequency control of motor speed

Fully Automatic Napkin Paper Production Line

Integrated Process: Combines printing (optional), glue lamination (optional), embossing, folding, and cutting and automatic transfer in one seamless workflow.

Customization: Adjustable napkin paper size, per-bag tissue count, and multi-pack configurations to meet client specifications.

Smart Control: Industrial HMI touchscreen with real-time monitoring, parameter wizard, and multi-level menu management.

Unmanned Safety: PLC-controlled interlocks, E-stop protection, and blade anomaly detection for zero manual intervention.

Efficiency Boost: Automated napkin paper packaging machine (single/multi-bag) with fault tracing to minimize downtime and labor costs.

The Automatic Paper Napkin Machines are of high efficiency, reliable and easy to operate. The high speed paper folder is quite useful for those who deal in supplying big quantities,it’...

1. Transmission belt drive configuration 2. Color printing device adopts flexible printing, the design can be flexibly according to you need replace, use professional color printing ani...

1.XY-OQ-7000A Automatic transfer napkin paper folding machine 2.XY-BT-298 High speed napkin paper packing machine 3. Speed: 1000 sheets/min 4. Power: 4.5KW (380V 50Hz 3Phase) 5. Raw pap...

.jpg)

with clear controls and stable performance. It runs smoothly with minimal adjustments, reduces operator effort, and provides efficient, reliable production, making the overall working experience convenient and satisfying.2025-09-01

The Automatic Transfer Napkin Tissue Paper Folding Machine and consistent output, significantly improving production speed while reducing manual labor.Zach 2025-09-01

The High Speed Napkin Tissue Paper Folding Machine greatly enhances production efficiency by increasing output capacity, ensuring precise folding quality, It streamlines the process, saves labor costs, and delivers consistent results, significantly improving overall manufacturing performance.Max 2025-09-01

the after-sales service is prompt, professional, and supportive, ensuring smooth operation and quick issue resolution.Carrier 2025-09-01