![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-GU-20A

Model:

XY-GU-20A

![]() Power:

30KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

30KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

facial tissue folding machine

Application:

facial tissue folding machine

![]() Weight:

4.5 tons (depends on the jumbo roll width)

Weight:

4.5 tons (depends on the jumbo roll width)

![]() Output:

facial tissue

Output:

facial tissue

![]() Packaging Dimension:

5000*2000*2100mm(depends on the jumbo roll width)

Packaging Dimension:

5000*2000*2100mm(depends on the jumbo roll width)

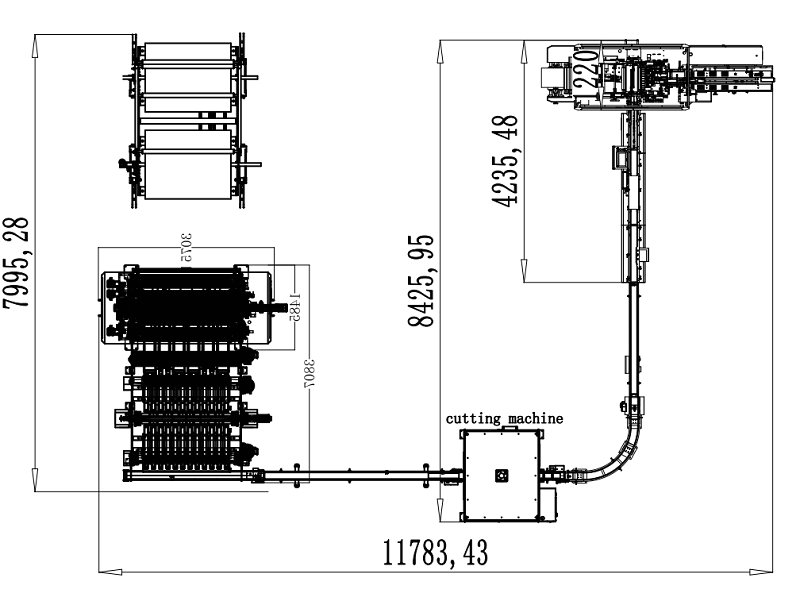

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Main functions

This advanced production line processes jumbo rolls by first slitting them to the required width using precision cylinders, then converting them into perfectly interfolded rectangular tissue sheets. The system features automatic marking capabilities and delivers high-speed operation, flawless folding precision, and user-friendly controls.

Key Advantages:

1. Ultra-Stable Performance – Heavy-duty wallboard rack ensures exceptional running stability even at high speeds

2. Flexible Width Adjustment – Produces multiple product widths according to specifications

3. Integrated Embossing System – Special embossing unit securely bonds tissue plies

4. Smart Auto-Stop Function – Immediately halts operation during paper breaks to prevent material waste

Outline:

Design Speed:100m/min

Stable Speed:70-80m/min, or Max. number of long stacks: 6-10 long stacks/min(meet only one of them)

Max.Width of jumbo roll:1400mm

Daily Capacity:about 7.5T/22 hours (jumbo roll:three layers and 15g/m²)

Jumbo roll paper:2-3 ply

Raw Material of jumbo roll:straw paper,wood pulp paper,sugarcane pulp paper,bamboo pulp paper and so on

Jumbo Roll Specification:2 ply:14-18g/m²/ply;3 ply: 13-15g/m²/ply

Note: The above output calculation is for reference only. The specific production capacity is related to the base paper weight, base paper characteristics, product specifications and the specific conditions of each company.

|

Name

|

Automatic transfer facial tissue folding machine

|

|

Speed

|

80-100m/min

|

|

Overall size(L*W*H)

|

8500*2250*2000mm

|

|

Weight of raw paper

|

(14-18)*2gsm

|

|

Power

|

35.3KW (380V,50HZ,3phase)

|

After Sales Service

(1), All our machine will have Two years guarantee

(2), Within two year after receiving our machines, Under right operation and non-artificial reasons, If there are any damaged parts or accessories, We will replace them by DHL or Fedex immediately FREE OF CHARGE.

(3), After two year warranty, Spare parts and damaged parts will be charged at cost price. If there is something wrong with the machine, We are responsible to solve this problem soonest, and help customers to restore production as soon as possible.

(4), After the machines arrive, the sellers shall send technician to install the production line(if need). And the buyer shall pay their round-trip air tickets from China factory to buyer's factory, the charge of visa, food ,transportations and accommodation in buyer's city.

|

No. |

Description |

Technical parameters |

|

1 |

Max. width of jumbo roll(mm) |

1440 |

|

2 |

Jumbo roll diameter(mm) |

<=¢1500 |

|

3 |

Unwinding speed(m/min) |

<130 |

|

4 |

Inner diameter of jumbo roll |

¢76.3mm |

|

5 |

Machine structure |

Wall type and frame structure |

|

6 |

Weight of jumbo roll(T) |

Max.0.8 |

|

7 |

Uncoiling system |

Sheet base belt paper feeding belt |

|

8 |

Alignment of jumbo roll |

Manual adjustment |

|

9 |

Unwind Mode |

Clockwise |

|

10 |

Paper threading method |

Manual |

|

11 |

Detection of paper break |

With a paper break detection system, the whole machine will stop when a paper break occurs, reducing the waste of raw paper |

|

12 |

Power |

1.5KW |

|

13 |

Minimum air pressure requirement |

0.6Mpa |

|

14 |

Gas consumption |

1000 liters/shift |

|

15 |

Transfer mode of jumbo roll stands |

Independent motor to control |

|

|

Transmission |

|

|

16 |

Conveyor belt |

Flat belt drive |

|

17 |

Jumbo roll adjustment |

Screw drive |

|

|

Other |

|

|

17 |

Protection |

The main transmission components are protected by a protective cover |

1. Automatic counting points a whole row output

2. Helical blade shear, vacuum adsorption folding

3. Stepless speed regulation unwind and can adapt to rewind high-low tension paper material

4. Adopt PLC computer programming control, pneumatic paper and easy to operate;

5. Frequency conversion control, saves energy.

6. The product width is adjustable, to meet different market requirement.

7. Supporting paper rolling pattern device, pattern obvious, flexible to market demand. (The embossing pattern is chosen by the customers ).

8. It can make “V”type single layer towel and two layers glue lamination .(Optional)

1. Adopt automatic feeding, open box, insert box, coding and sealing, Reasonable compact structure, easy operation.2. Adopt Servo motor, touch screen and PLC programmable control system...

1. PLC controlling system 2. Servo drives 3. Frequency converter 4. Yudian temperature module 5. up-to-dated touch screen integrated to control and driving center,with faster calculati...

Cyclotron paper cutter is used to automatically cut off a row folded and round roll paper towel products, such as the removable tissue or toilet roll paper. The whole machine adopts ser...

XY-AI-500 Automatic jrt jumbo roll maxi roll tissue cutting machine Features: 1.The main motor using the inverter independent drive. 2.For one set of machine, the cutting di...

XY-GU-27 Best quality semi auto napkin paper plastic bag packing machine Main Features : 1.This machine automatically bagging and gusset sealing and cutting. 2.Using advanced P...

XY-TQ-B-400 Wall Type StructureAutomatic Toilet Paper Band Saw Production Line Contain below machines:rewinding machine、cutting machine、packing machine XY-TQ-2800B ...

The Facial Tissue Machine offers high efficiency, stable performance, and easy operation, and supports energy-saving production with reliable output.Wei 2025-09-02

The Automatic Facial Tissue Cutting Machine provides smooth operation, precise cutting, and consistent size. and delivers a reliable, user-friendly experience.Cesar 2025-09-02

The facial tissue machine touchscreen interface is user-friendly, and the energy-saving mode reduces costs by 10%. Worth every penny for startups in the paper product industry.2025-11-04

Perfect for our eco-friendly facial tissue packaging line! The machine produces soft facial tissue paper with minimal downtime2025-11-04