![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-503IZ

Model:

XY-503IZ

![]() Power:

15.2KW 380V 50HZ 3Phase

Power:

15.2KW 380V 50HZ 3Phase

![]() Application:

Individual toilet paper roll packing machine

Application:

Individual toilet paper roll packing machine

![]() Weight:

1800kg

Weight:

1800kg

![]() Output:

Individual packing toilet paper roll

Output:

Individual packing toilet paper roll

![]() Packaging Dimension:

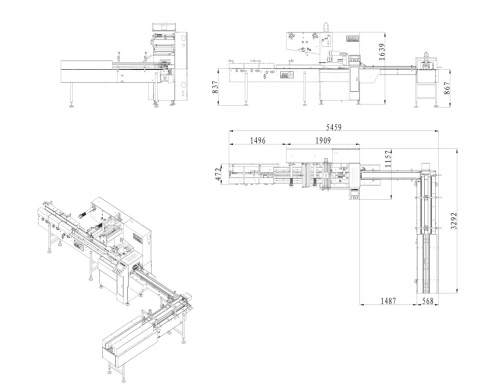

5459*3292*2100mm

Packaging Dimension:

5459*3292*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Features:

1. Multi-functionality: Servo-controlled operation with automatic conveying, feeding, sealing, and counting.

2. Advanced control system: Equipped with PLC computer programming and an LCD text display for easy parameter settings. Precise temperature control ensures efficient protection of heating wires and thermally stable tapes.

3. Aesthetic & efficient packaging: Delivers neat and tidy sealing. Fully automated operation with a conveyor for seamless integration into a complete packaging line, enhancing productivity and reducing labor costs.

4. User-friendly design: Low maintenance requirements and quiet operation.

5. Intuitive touchscreen control: Allows effortless adjustments of speed, roll size, and film size via the touchscreen interface.

6. Smart safety features: Electric eye detection triggers automatic shutdown in case of malfunctions.

7. Independent temperature regulation: Ensures optimal performance for different materials.

8. High capacity: 80–200 rolls per minute.

9. Versatile compatibility: Suitable for both core and coreless toilet paper rolls and kitchen towel

10.Durable construction: Rigid frame design with high-quality components ensures stable, efficient operation and extended machine lifespan.

11. Line integration capability: Can be connected with toilet paper log saw cutting machines and multi toilet paper packing machines to form an automated production line.

Technology Parameter:

1. Speed: 150-200 pack/min

2. Diameter of finished products: 90-130mm

3. Length of finished products: 80-220mm

4. Max width of film(mm): 430

5. Power: 15.5KW 380V 50HZ 3Phase

6.Material of film: BOPP,SPP,CPP(as usual, use CPP)

7.Blade: double blade

8. Overall Dimension: 5459*3292*2100mm

9. Weight: 1800KG

1. The super speed individual small toilet paper roll packing machine is designed for core or coreless toilet paper rolls and kitchen towel, offering fully automated packaging.

2. Paper feeding, film feeding, longitudinal sealing, cutting, coreless paper exhaust, and reversing operations are driven by servo control. This method ensures complete function configuration, high efficiency, simple operation, wide adaptability, quick specification changeover, easy maintenance, and low operating costs.

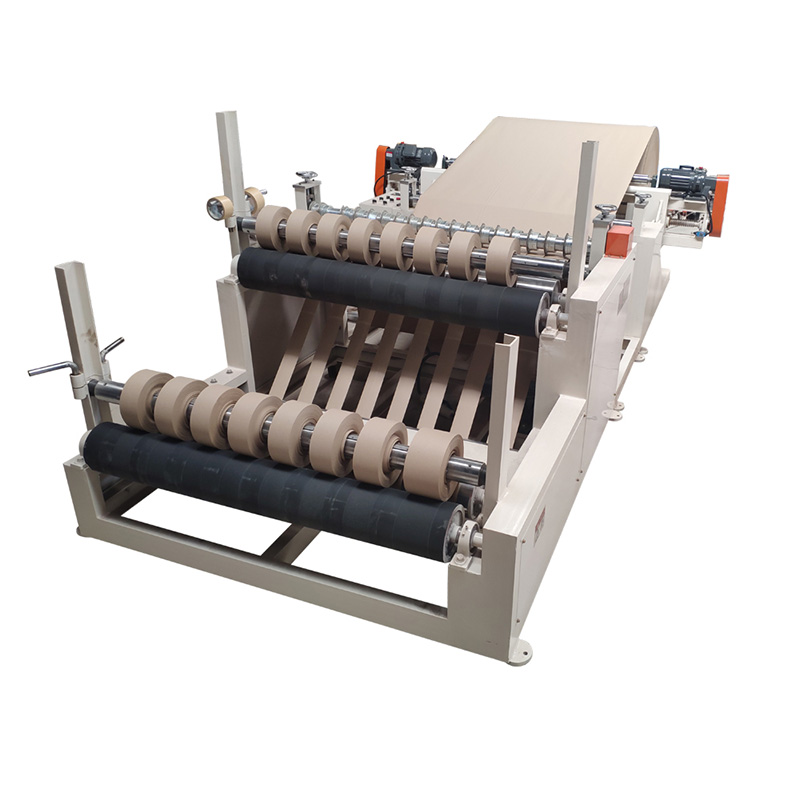

Type XY-AI-1092 XY-AI-1575 Slitting Width Adjustable Raw Material Size ≤φ1200*1100mm ≤φ1200*1700mm Production Speed ...

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

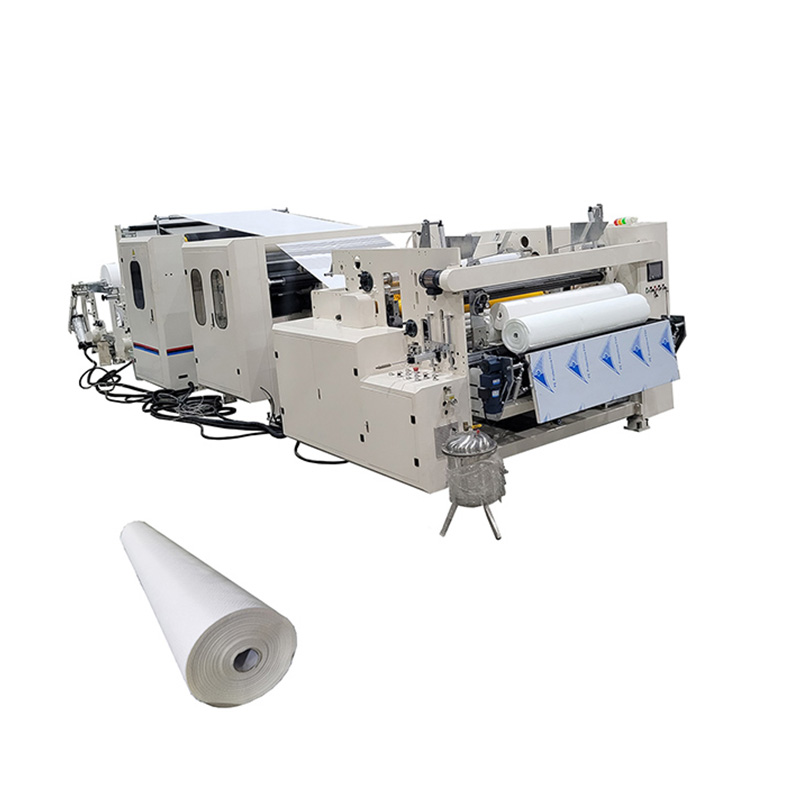

This high-speed glue lamination machine is designed for manufacturing toilet paper rolls, kitchen towels, and maxi rolls. It features a rewinding diameter range of 80-300mm and incorpor...

This kitchen towel machine exceeded expectations! good effect of kitchen towel made a huge difference, and the support team was helpful throughout the process2025-11-04

Switched to this machine for eco-friendly production. The toilet paper feels luxurious and leaves no residue. Delivery was faster too2026-01-26

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04