![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-G

Model:

XY-TQ-G

![]() Power:

12KW 380V 50HZ 3Phase

Power:

12KW 380V 50HZ 3Phase

![]() Application:

big diameter maxi roll paper making machine

Application:

big diameter maxi roll paper making machine

![]() Weight:

3 tons ( Depends on the jumbo roll width)

Weight:

3 tons ( Depends on the jumbo roll width)

![]() Output:

big diameter maxi roll paper

Output:

big diameter maxi roll paper

![]() Packaging Dimension:

5000*3200*2100mm(depends on the jumbo roll width)

Packaging Dimension:

5000*3200*2100mm(depends on the jumbo roll width)

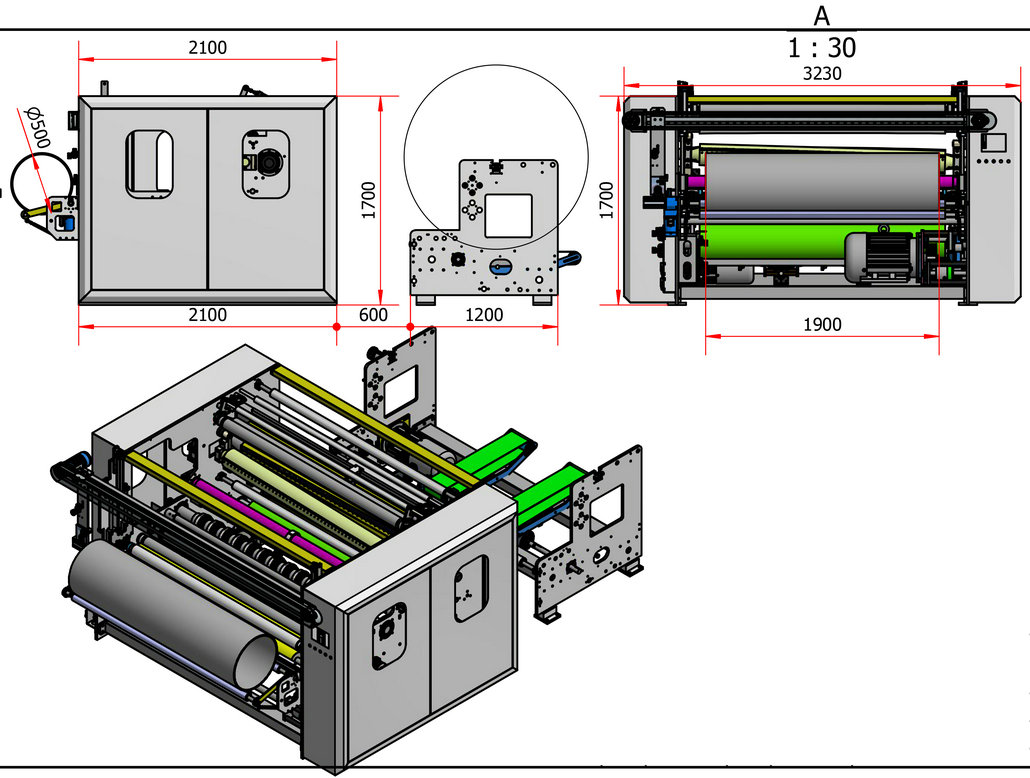

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Function and Features:

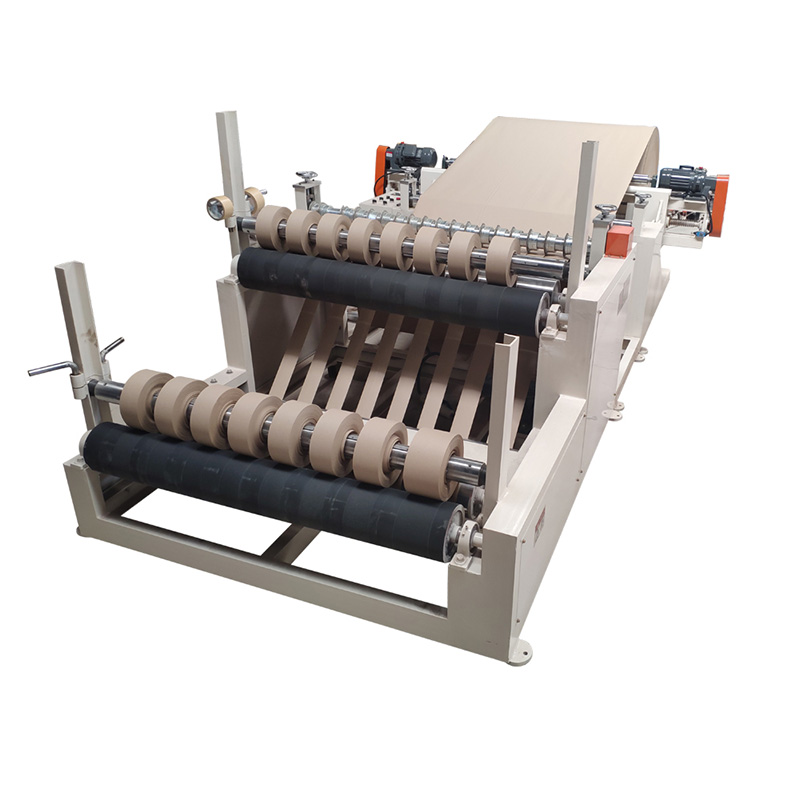

1. Inflatable Shaft Winding: Ensures precise positioning of the paper tube, making alignment simple and accurate.

2. Edge Pressing System: Features steel-on-steel blank pressing with independent cylinder adjustment, allowing for easy alignment to prevent misalignment between paper layers.

3. Horizontal Unwind Stand: Equipped with a pneumatic paper loading unit to eliminate the need for manual handling.

4. Pneumatic Wide-Belt Paper Feeding: Incorporates a separate tension control device for each roll of raw material to ensure consistent tension.

5. Traction System with Switch Base Paper: Uses a pre- and post-switch traction mechanism, making operation simpler and safer.

Technician parameter:

1. Speed: 180-200m/min

2. Slitting width:100mm( adjustable)

3.Slitting diameter: 500 mm(max)

4. Diameter of paper core:76 mm

5. Size of jumbo roll: 2000 mm width and 1200 diameter

6. Power: 14Kw 380V 60 Hz three-phase

7. Overall size: 6200*2400*1800 mm

8.Weight:4T

9. with one set embossing roller

10. Wall board thickness: 20mm

A high-speed, large-diameter maxi roll paper making machine is a specialized piece of equipment designed to rewind and slit jumbo rolls of paper into large, reel-shaped toilet paper rolls. These rolls are primarily used in high-traffic public restrooms, such as those found in hotels, airports, shopping malls, and other commercial facilities. The big-diameter maxi rolls produced by these machines are particularly well-suited for heavy-duty use and are in high demand in regions like the Middle East, where they are widely adopted due to their efficiency and durability.

I. Intelligent Sharpening System 1. Equipped with an intelligent sharpening device (integrated with the human-machine interface): - Motor-driven grinding wheel 2. Three-dimensiona...

This equipment is the latest model independently developed by the company in combination with the current market usage. The equipment adopts PLC programming control, large-screen tru...

Type XY-AI-1092 XY-AI-1575 Slitting Width Adjustable Raw Material Size ≤φ1200*1100mm ≤φ1200*1700mm Production Speed ...

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

This machine is a game-changer! The toilet paper rolls it produces are soft yet strong, just like premium brands. Worth every penny!"2026-01-26