![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

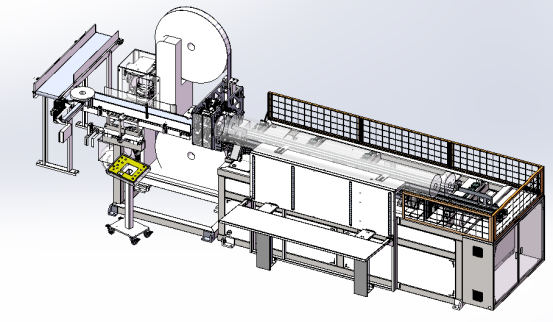

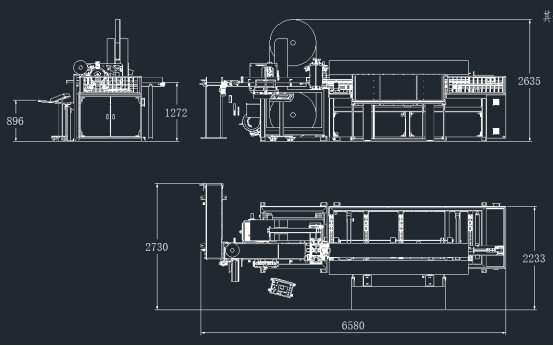

XY-AI-500

Model:

XY-AI-500

![]() Power:

15KW 380V 50HZ 3Phase

Power:

15KW 380V 50HZ 3Phase

![]() Application:

Maxi paper towel roll band saw cutting machine

Application:

Maxi paper towel roll band saw cutting machine

![]() Weight:

2.5 tons

Weight:

2.5 tons

![]() Output:

maxi paper towel roll

Output:

maxi paper towel roll

![]() Packaging Dimension:

6580*2800*2100mm

Packaging Dimension:

6580*2800*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

I. Intelligent Sharpening System

1. Equipped with an intelligent sharpening device (integrated with the human-machine interface):4. Integrated intelligent dust collection device for full control of grinding dust

- Compressed Air Requirement: 0.6MPa ±10%

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

Main function and feature: 1. Enhanced Paper Feeding: A widened belt on the backstand increases friction during paper feeding for improved stability. 2. Precision Transmiss...

This production line consists of : 1. XY-TQ-B A utomatic color printing m axi ki tchen towel roll rewinding machine Feature and Function 1. Aut...

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02