![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-E

Model:

XY-TQ-A-E

![]() Power:

100KW 380V 50HZ 3Phase

Power:

100KW 380V 50HZ 3Phase

![]() Application:

Non stop lamination toilet paper and kitchen towel machine

Application:

Non stop lamination toilet paper and kitchen towel machine

![]() Weight:

15 tons

Weight:

15 tons

![]() Output:

lamination toilet paper and kitchen towel

Output:

lamination toilet paper and kitchen towel

![]() Packaging Dimension:

21060*18657*5000mm

Packaging Dimension:

21060*18657*5000mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

1. XY-TQ-B Non stop automatic toilet paper and kitchen towel rewinding machine

Features:

2. XY-SD-B Automatic conveyor Paper core machine

Features:

Paper core forming mode:Vertical, flat belt pressure winding

Paper core cutting way: Cylinder control cutting

Working mode of cutter: Adopt guide rail type cutting;

Lubrication system: Lubrication device for the first paper

Glue device : Manual device can stop the machine and separate the paper from the sizing wheel automatically

3. XY-AI-280 Automatic toilet paper and kitchen towel log saw cutting machine

Features:

The cylinder pushes the grinding wheel to contact the circular knife to realize passive sharpening. The sharpening parameters can be adjusted and controlled by touch screen.

4. XY-AI-399 Full Automatic Toilet Roll And Kitchen Towel Bundling Wrapping Machine

Features:

1. XY-TQ-B Non stop automatic toilet paper and kitchen towel rewinding machine

Technical Parameters:

1. Backstand part: 2sets

2. Jumbo roll paper diameter: max. 2500mm

3. Jumbo roll paper width: max. 2850mm

4. Production speed: 250m/min

5. Rewinding diameter: 90-140mm

6. 3 inch shaft sleeve for backstand : 2sets

7. Conveying and gluing device for paper core unit: 1set

8. Tail Glue Sealing machine: 1set

9. Log roll accumulator: 1set (130log roll can be stored)

10. Electrical control system

2. XY-SD-B Automatic conveyor Paper core machine

Technical Parameters:

1.Speed:45-70m/min

2. Paper core diameter: 40-76mm (Need to confirm in advance)

3.The layer number:2-4layer

4. Power:17KW 380V 50HZ 3Phase

5.Paper core length adjustment: Touch screen to adjust

6.Cutting device:Circular blade, pneumatic slitting

3. XY-AI-280 Automatic toilet paper and kitchen towel log saw cutting machine

Technical Parameters:

1. Speed: 100 cuts/min

2. Cutting diameter: 90-140mm

3. The width of jumbo roll: 2800mm

4. Cutting length: 80-280mm

5.Controlled by panel, control accuracy is ± 2mm

4. XY-AI-399 Full Automatic Toilet Roll And Kitchen Towel Bundling Wrapping Machine

Technology Parameter:

1. Speed: 20-120 packs/min

2. Size range bag Max: L600*W480*H300(mm)

3. Toilet tissue roll: 2-60rolls Kitchen towel :1-24 rolls

4. Power supply: 380V 50HZ 3Phase

5. Mini air pressure requirement: 5Mpa

6. Wrapping Material: PE,PP,PPE,OPP,CPP,PT Plastic film

7. PE thickness,LDPE 25-40 microns

8. Surface: carbon steel

9. Power consumption: 31 KW

10. Machine size: L8500mm*W4500mm*H1800mm

11. Machine weight: 8000kg

12. Color: white or custom

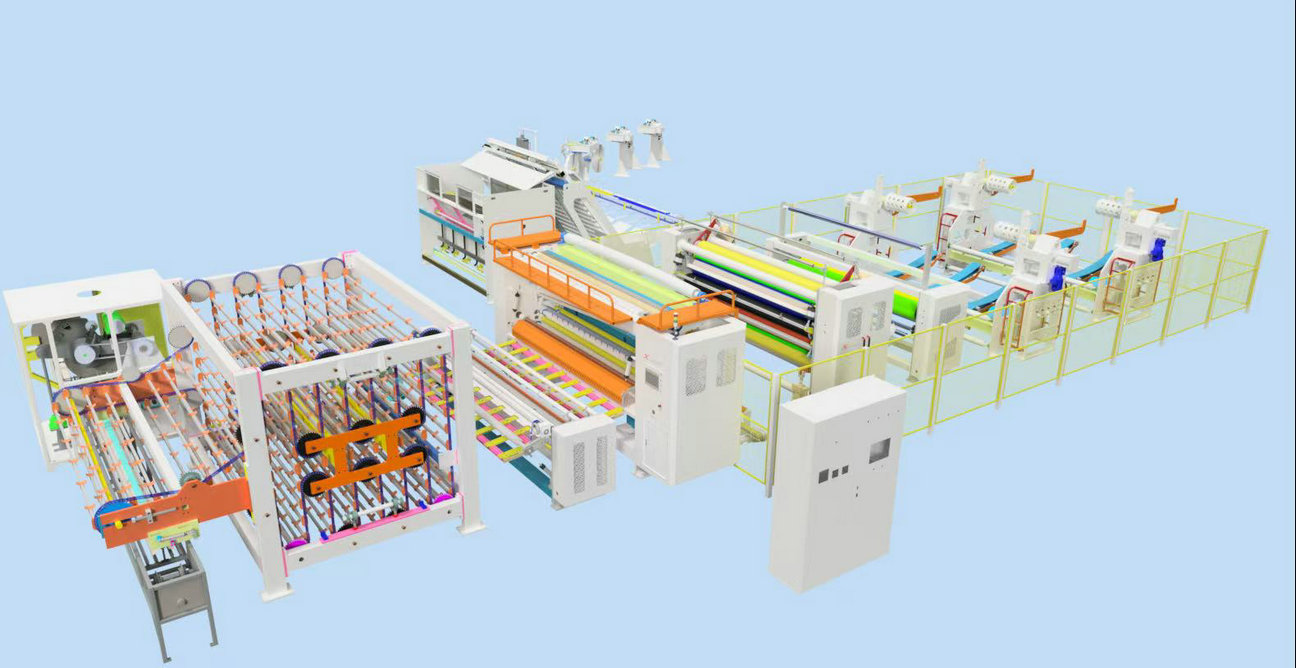

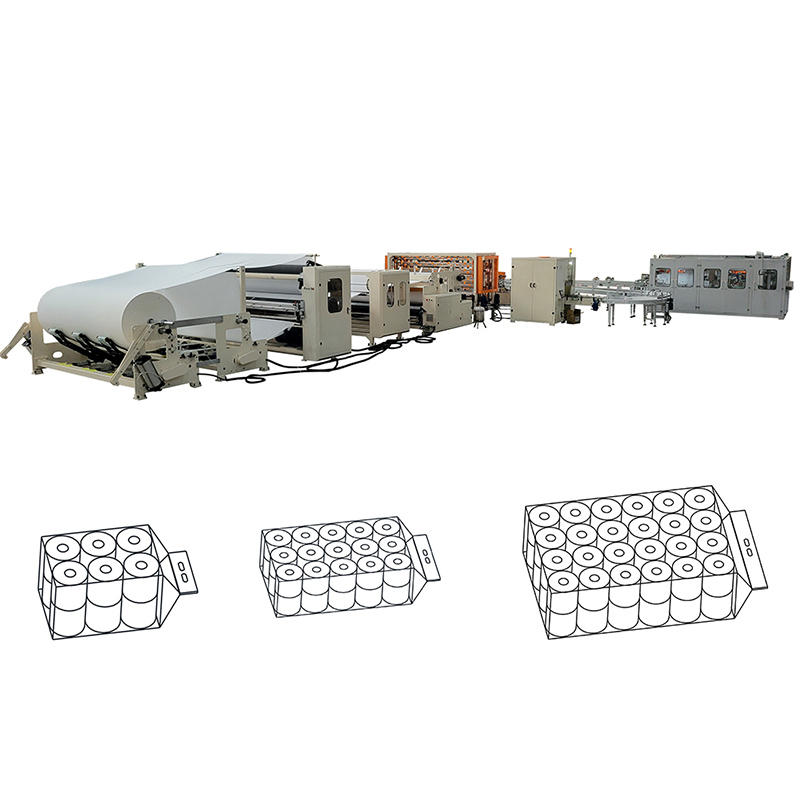

This non stop lamination toilet paper and kitchen towel making machine production line including 4 sets machine:

1. XY-TQ-B Non stop automatic toilet paper and kitchen towel rewinding machine

2. XY-SD-B Automatic conveyor Paper core machine

3. XY-AI-280 Automatic toilet paper and kitchen towel log saw cutting machine

4. XY-AI-399 Full Automatic Toilet Roll And Kitchen Towel Bundling Wrapping Machine

The non stop toilet tissue paper production line is composed of a large jumbo roll stander, an glue lamination embossing unit (optional), a two color printing unit(optional), a high-speed continuous rewinding main unit, an tail glue (or non tail glue) sealing machine, a large paper roll accumulator, a high-speed paper roll log saw cutting machine, a high-speed paper core winding machine, a paper core accumulator (optional), and automatic tissue paper packaging machines of various specifications and packaging forms. All functional units and accessories work together seamlessly and operate smoothly, making it an ideal equipment for producing toilet paper and color printing kitchen paper.

Model cutting and sealing machine temperature shrink machine Power source 220V 50Hz/60Hz 380V 50/60Hz Rated Power 1.35KW ...

1. XY-TQ-B High speed small kitchen towel and toilet paper roll rewinding machine. 2. XY-203 Log roll paper accumulator. 3. XY-AI-280 Automatic kitchen paper and toilet roll log saw Cut...

1. XY-TQ-B High speed kitchen towel paper / toilet paper / maxi roll rewinding machine 2. XY-203 Log roll paper accumulator 3. XY-AI-400 High speed small kitchen paper / toi...

Finally, no more bulky store trips! The machine delivers consistent quality—soft, absorbent, and durable. Packaging is minimal and recyclable2026-01-26

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

they walked us through the installation and provided training. Highly recommend for manufacturers looking to scale up2025-11-04

Switched to this machine for eco-friendly production. The toilet paper feels luxurious and leaves no residue. Delivery was faster too2026-01-26