![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-AI-400

Model:

XY-AI-400

![]() Power:

7.5KW 380V 50HZ 3Phase

Power:

7.5KW 380V 50HZ 3Phase

![]() Application:

Small toilet paper cutting machine

Application:

Small toilet paper cutting machine

![]() Weight:

1.8 tons

Weight:

1.8 tons

![]() Output:

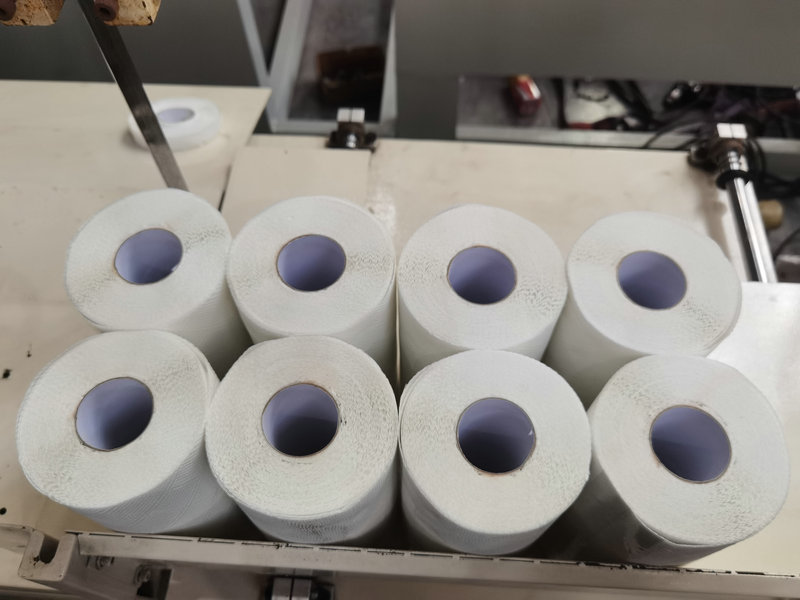

small toilet paper

Output:

small toilet paper

![]() Packaging Dimension:

4500x1500x2100mm

Packaging Dimension:

4500x1500x2100mm

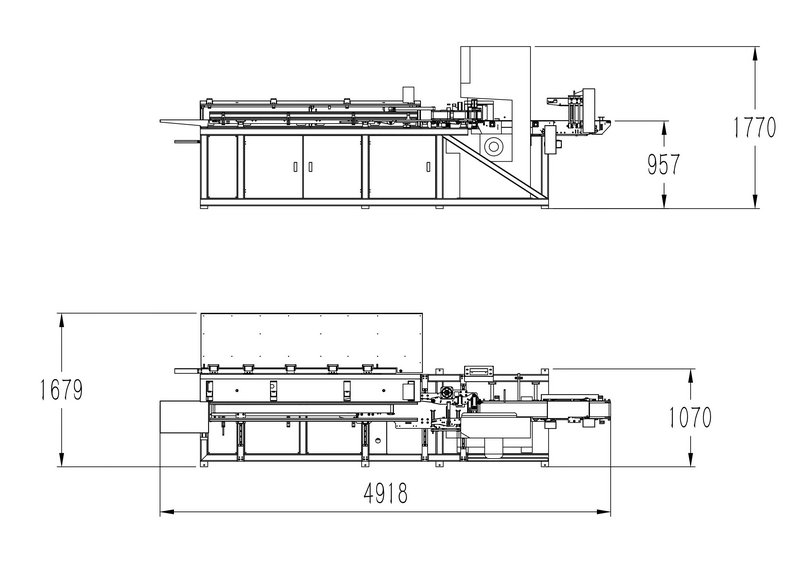

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

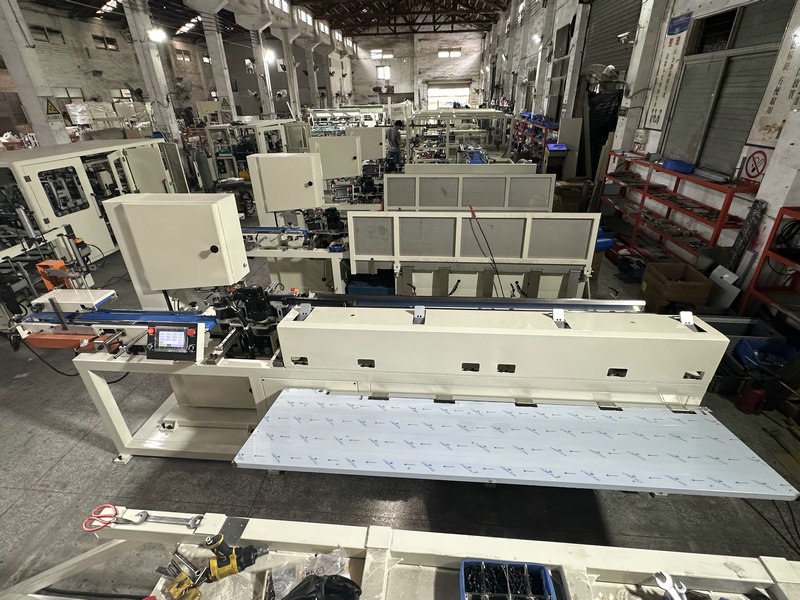

Overview

This equipment is the latest model independently developed by the company in combination with the current market usage.

The equipment adopts PLC programming control, large-screen true color human-machine interface operation, precise servo control feeding length, mechatronic control and other international advanced technologies, can automatically detect each key action, and has a complete fault information prompt system, so that the entire production line can reach the best working state.

Main technical parameters

|

|

unit |

parameters |

Remarks |

|

|

Weight |

KG |

1300kg |

|

|

|

Speed |

Cuts/min |

100~120 |

|

|

|

Cutting channel |

|

1 |

|

|

|

Cutting Knife |

Band saw |

3750*50*0.5 |

|

|

|

Log roll length |

mm |

≤2850mm |

Accept customization |

|

|

Cutting deviation |

mm |

±1mm |

|

|

|

Cutting range |

length |

mm |

≤400 |

Accept customization |

|

diameter |

mm |

90-150mm |

Accept customization |

|

|

Power |

KW |

6 |

|

|

|

|

380V/50HZ |

|||

Q: Are you trading company or manufacturer

A: We are factory.

|

Cutting speed |

80~100cuts/minute |

|

Cutting blade |

band saw blade(Size 3750*50*0.5) |

|

Toilet log length |

≦2850mm(it can be made according to customer request) |

|

Finished toilet roll length |

≦300mm |

|

Finished toilet roll diameter |

70-130mm |

|

Cutting tolerance |

±1.5mm |

|

Power supply |

7.5kw 380V 50Hz |

|

Overall size |

4918x1600x2100mm |

|

Machine weight |

1500KG |

1、When the paper can not be cut down, the equipment will automatically stops and gives an alarm;

2、The high precision servo system is used in the feed motor servo system, to ensure the quality of the finished product;

3、The equipment automatically calculate the quantity of the finished product being cut; according to the raw material and the length of the finished product;

4、When data input is incorrect, the equipment breaks off and prompts to adjust on the interface;

5、The waste paper head and paper end can be automatically sorted;

6、The automatic sharpening knife system is used in the equipment, can adjust the sharpening knife system according the requirement of paper being cut, which increase the cutting life;

7、The sharp steel wheel is used in the sharpening knife system, which increase the sharpening knife efficiency .

Main function and feature: 1. Enhanced Paper Feeding: A widened belt on the backstand increases friction during paper feeding for improved stability. 2. Precision Transmiss...

This production line consists of : 1. XY-TQ-B A utomatic color printing m axi ki tchen towel roll rewinding machine Feature and Function 1. Aut...

1. XY-TQ-B Automatic lamination toilet paper making machine Feature and Function 1. Automatic Core Feeding Rewinding System Features automated log pusher post-rew...

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04