![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-G

Model:

XY-TQ-A-G

![]() Power:

22KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

22KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

10 rolls small toilet paper roll making machine production line

Application:

10 rolls small toilet paper roll making machine production line

![]() Weight:

6 tons( depends on the jumbo roll width)

Weight:

6 tons( depends on the jumbo roll width)

![]() Output:

10 rolls small toilet paper roll

Output:

10 rolls small toilet paper roll

![]() Packaging Dimension:

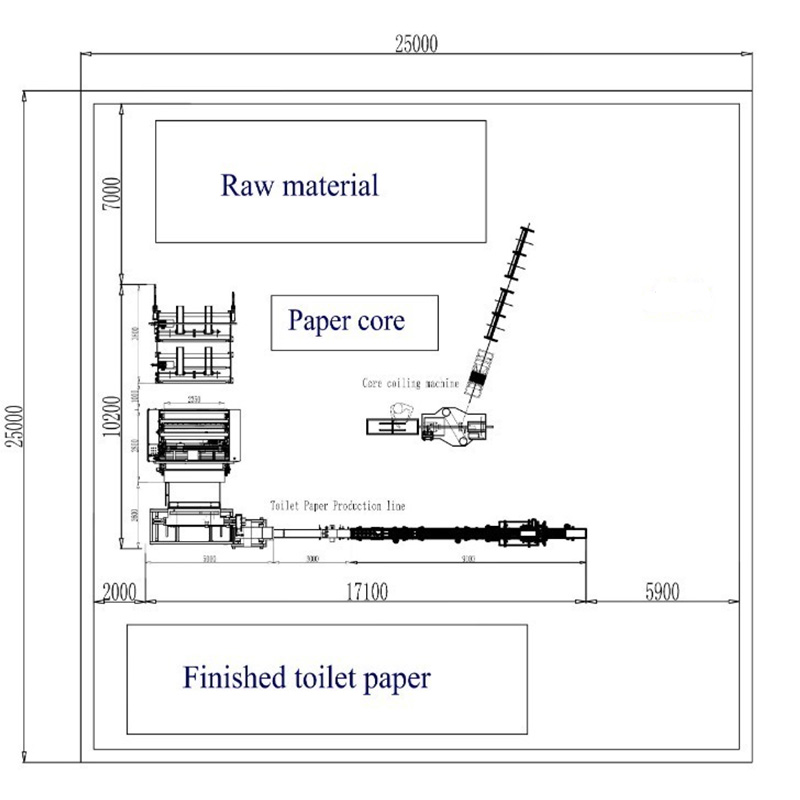

25000*25000*2100mm

Packaging Dimension:

25000*25000*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

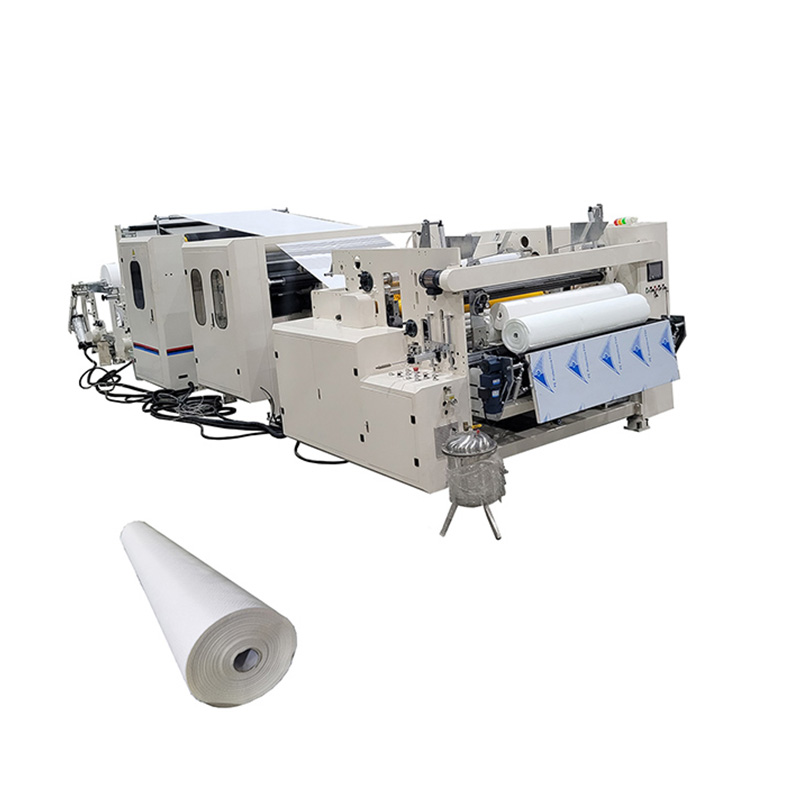

This production line including 3 machines:

1. XY-TQ-B High speed small toilet paper rewinding machine

Function and Features:

1. Automatic core feeding system, automatic log pusher after rewinding, then rewinding the new log again.

2. Automatic edge-trimming, core feeding, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

4. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

6. Embossing Unit: adopt point to point embossing rollers, making the two layers match well, the paper is soft and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

2.XY-AI-400 Automatic toilet paper cutting machine

Feature and function:

1、When the paper cannot be cut down, the equipment will automatically stops and gives an alarm;

2、The high precision servo system is used in the feed motor servo system, to ensure the quality of the finished product;

3、The equipment automatically calculate the quantity of the finished product being cut; according to the raw material and the length of the finished product;

4、When data input is incorrect, the equipment breaks off and prompts to adjust on the interface;

5、The waste paper head and paper end can be automatically sorted;

6、The automatic sharpening knife system is used in the equipment, can adjust the sharpening knife system according the requirement of paper being cut, which increase the cutting life;

7、The sharp steel wheel is used in the sharpening knife system, which increase the sharpening knife efficiency

3.XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

Feature and function:

1. Multi function: automatic conveying, single head operation, automatic feeding, automatic sealing, automatic countering.

2. Adopting the advanced PLC computer programming control and employing the liquid crystal text to display parameters, it is with simple set and water cooling control. Moreover, its temperature controlling is more precise so that heating wires and tapes with thermo stability can be protected more efficient. The machine use the servo motor to push the products to the bags, it causes to locating the products more accurately.

3. Packing and sealing are pretty and tidy. The machine can be operated with full-automation and semi-automation. The machine with conveyer can be connected with automatic toilet roll packing machine with conveyer. This allows the machine have high capacity and therefore to save the labor and reduce production cost.

4. Capacity: 8-12 bundling bag/min, 1 labor only to pack.

5. Suitable for core or coreless toilet roll. The machine cannot proofread color code automatically.

6. Comprehensive design, rigid frame, and imported major component, this allows our machine work steadily& efficiently, and therefore this makes our machine have long life.

This production line including 3 machines:

1. XY-TQ-B High speed small toilet paper rewinding machine

Technical parameter:

1. Production speed: 200-230 m /min

2. Power:15kw (380V 50Hz 3Phase)

3. Max. diameter of jumbo roll paper : 1200mm, jumbo roll width 1850mm

4. Diameter of jumbo roll paper inner core: 76.2mm

5. 1850mm width of jumbo roll.

6. Weight : About 4T

7. Two sets paper standers (Individual motor to control the tension) and one sets of steel to rubber embossing roll for toilet paper

8. 20mm thickness of wall board of machine

9. Diameter of finished toilet paper: 90-280mm

10. Diameter of finished toilet paper inner core: 38-76mm

11. Perforation distance: 4 anvil Blades(90-150mm)

12. Overall size(L*W*H): 6500*2800*2100mm

13. Individual motor for each jumbo roll stander, PLC control the tension of paper

2.XY-AI-400 Automatic toilet paper cutting machine

Technical parameter:

1. Cutting speed: 80-100cuts/minute

2. Cutting blade: band saw blade(Size 3750*60*0.6)

3. Toilet log length: 2850mm

4. Finished toilet roll length: max. 250mm

5. Finished toilet roll diameter: 90-120mm

6. Cutting tolerance: ±1.5mm

7. Power supply: 7.5kw 380V 50Hz 3Phase

8. Overall size: 2800*1500*2100mm

9. Machine weight: 1100KG

3.XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

Technology Parameter:

1. Speed: 5-10bags/min

2. Diameter of finished products: 90-120mm

3. Length of finished products: 100-120mm

4. Height: of finished products: 100mm

5. Package type: 8rolls, 10rolls and 12rolls in one layer

6. Voltage: 3KW 380V 50HZ 3Phase

7. Overall Dimension: 8700*1000*1300 mm

8. Weight: 600KG

This production line including 3 machines:

1. XY-TQ-B High speed small toilet paper rewinding machine

2.XY-AI-400 Automatic toilet paper cutting machine

3.XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

This production line consists of fully automatic rewinding machine, automatic small toilet paper band saw machine and semi automatic toilet paper roll bundle packing machine.

From the jumbo roll into the finished rolls, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength. It’s best choice for the producing hygienic toilet paper products.

I. Intelligent Sharpening System 1. Equipped with an intelligent sharpening device (integrated with the human-machine interface): - Motor-driven grinding wheel 2. Three-dimensiona...

This high-speed glue lamination machine is designed for manufacturing toilet paper rolls, kitchen towels, and maxi rolls. It features a rewinding diameter range of 80-300mm and incorpor...

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

Switched to this machine for eco-friendly production. The toilet paper feels luxurious and leaves no residue. Delivery was faster too2026-01-26

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04