![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-B

Model:

XY-TQ-B

![]() Power:

35KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

35KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

Toilet paper & kitchen towel machine

Application:

Toilet paper & kitchen towel machine

![]() Weight:

5 tons (depends on the jumbo roll width)

Weight:

5 tons (depends on the jumbo roll width)

![]() Output:

toilet paper and kitchen towel

Output:

toilet paper and kitchen towel

![]() Packaging Dimension:

10000*2800*2200mm(depends on the jumbo roll width)

Packaging Dimension:

10000*2800*2200mm(depends on the jumbo roll width)

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Function and Features:

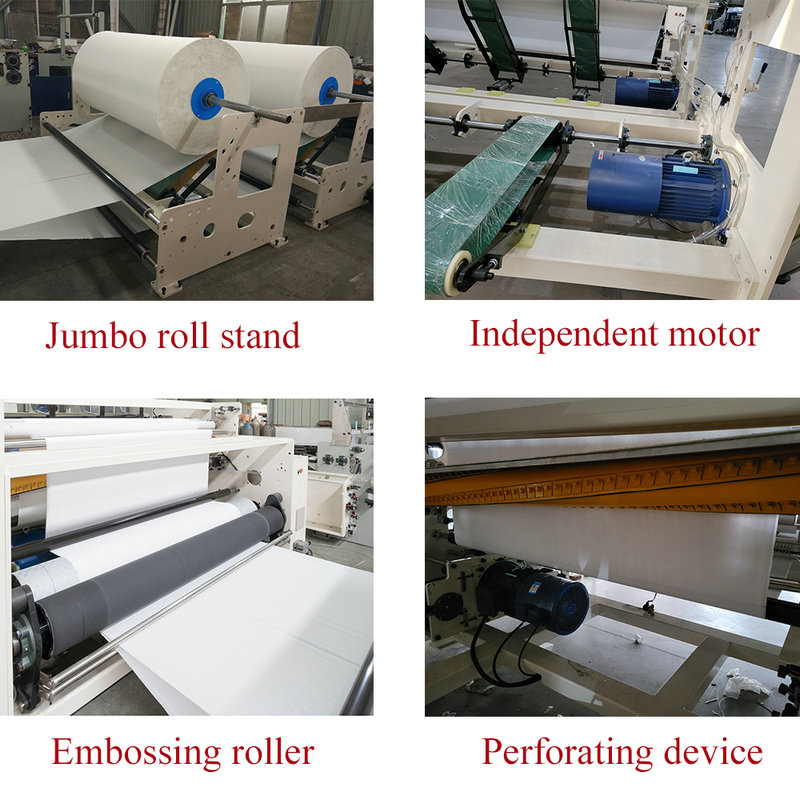

1. Automatic core feeding system, automatic log pusher after rewinding, then rewinding the new log again.

2. Automatic edge-trimming, core feeding, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

4. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

6. Embossing Unit: adopt point to point embossing rollers, making the two layers match well, the paper is soft and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

Main Technical Parameters:

|

Jumbo roll max width |

1750mm (Other size can be specified) |

|

Jumbo roll diameter |

Φ1200mm |

|

Jumbo roll inner core diameter |

3inches(76.2mm) |

|

Finish product diameter |

Φ70-φ280mm |

|

Finish product Inner core diameter |

φ38-φ76mm |

|

Perforation distance |

120-150mm |

|

Production speed |

180-230m/min |

|

PLC |

INVT |

|

Pneumatic system |

3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

|

Unwinding transmission |

Variable stepless speed regulation |

|

Rewinding Unit |

With core or coreless |

Packing:In wooden pallet, Most of the electrical and electronic components are equipped as per export standard.

Technical support:We can send one technician to the customer’s factory to install the machine and train their workers, and the expense for round-trip air-ticket, meal, accommodation and 120 dollar per day for the technician should be born by the customer.

Payment term:30% down payment should be paid by T/T, the 70% balance should be paid by T/T

After Sales Service

(1), All our machine will have Two years guarantee

(2), Within two year after receiving our machines, Under right operation and non-artificial reasons, If there are any damaged parts or accessories, We will replace them by DHL or Fedex immediately FREE OF CHARGE.

(3), After two year warranty, Spare parts and damaged parts will be charged at cost price. If there is something wrong with the machine, We are responsible to solve this problem soonest, and help customers to restore production as soon as possible.

(4), After the machines arrive, the sellers shall send technician to install the production line(if need). And the buyer shall pay their round-trip air tickets from China factory to buyer's factory, the charge of visa, food ,transportations and accommodation in buyer's city.

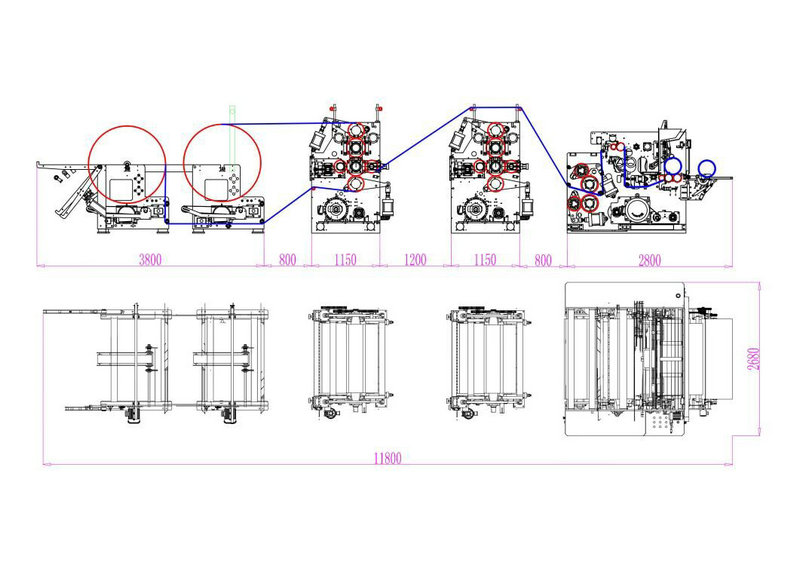

|

Model |

XY-TQ-B High speed glue lamination toilet paper kitchen towel making machine |

|

Jumbo Roll Max Width |

2800mm (Other size can be specified) |

|

Jumbo Roll Diameter |

1200mm(Other size can be specified) |

|

Jumbo Roll Inner Diameter |

3inches(76.2mm) (Other size can be specified) |

|

Perforation Distance |

4 anvil Blades(90-140mm) 2 anvil Blades(180-280mm) |

|

Finished Product Diameter |

90~280mm |

|

Finished Product Core Diameter |

38~90mm |

|

Production Speed |

180~230m/min |

|

Program Controller |

PLC(INVT brand) |

|

Unwind Stands |

2 Stands |

|

Pneumatic System |

3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provided by user) |

|

Main Power |

12KW 380V 50HZ 3 phase( depends on model) |

|

Dimension |

7000*4000*1900(L*W*H)( depends on model) |

|

Weight |

About 6T( depends on model) |

|

Edge Embossing |

Steel to steel (Pneumatic Control) |

|

Full Embossment |

Steel to rubber. |

1. The machine features a robust 20mm thick wall-type construction that ensures stable high-speed operation with minimal noise.

2. The perforation spacing can be adjusted to accommodate various product requirements.

3. The system includes automatic core feeding and log ejection functions, enabling continuous rewinding of new logs without manual intervention.

4. Integrated edge trimming, glue application, and sealing operations are performed simultaneously, with a 10-18mm tail remaining for easy rewinding - this process minimizes material waste and lowers production costs.

5. The equipment utilizes internationally advanced PLC control technology with touchscreen HMI for parameter setting and fault diagnosis display.

6. Dual wall-type back stands with pneumatic lifting mechanisms and wide flat drive belts allow independent adjustment of each jumbo roll.

7. Jog control switches facilitate safe and convenient paper threading operations.

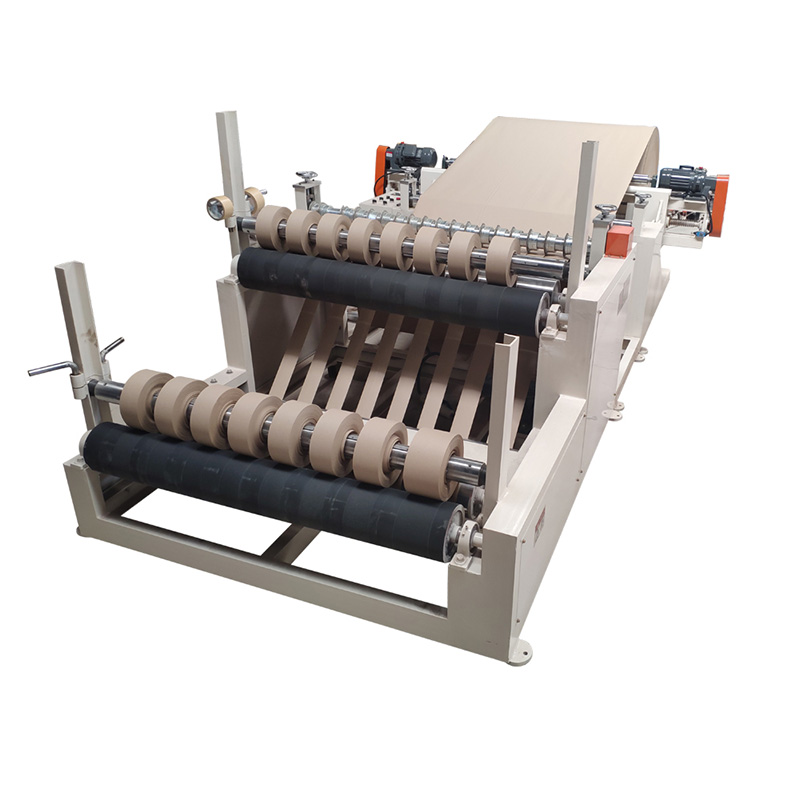

Type XY-AI-1092 XY-AI-1575 Slitting Width Adjustable Raw Material Size ≤φ1200*1100mm ≤φ1200*1700mm Production Speed ...

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

1. XY-TQ-B High speed kitchen towel paper / toilet paper / maxi roll rewinding machine 2. XY-203 Log roll paper accumulator 3. XY-AI-400 High speed small kitchen paper / toi...

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

This kitchen towel machine exceeded expectations! good effect of kitchen towel made a huge difference, and the support team was helpful throughout the process2025-11-04