![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-SD-B

Model:

XY-SD-B

![]() Power:

3.5KW 380V 50HZ 3Phase

Power:

3.5KW 380V 50HZ 3Phase

![]() Application:

Paper core roll making machine

Application:

Paper core roll making machine

![]() Weight:

1.2 tons

Weight:

1.2 tons

![]() Output:

Paper core roll

Output:

Paper core roll

![]() Packaging Dimension:

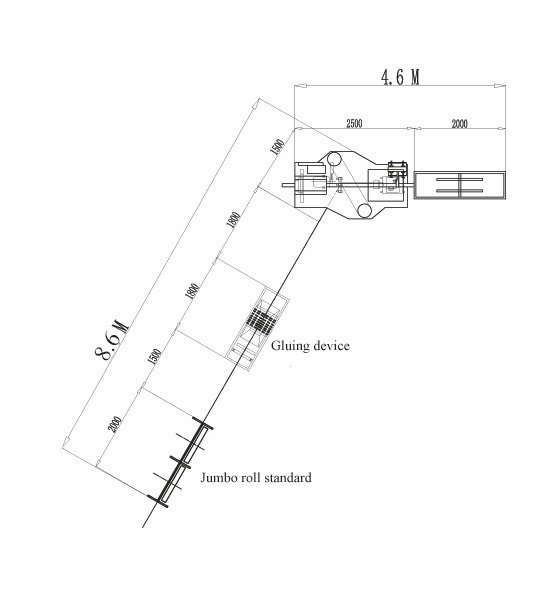

4600*8600*2200mm

Packaging Dimension:

4600*8600*2200mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Functions and features:

1. Inverter Control for Precision Length Measurement

The system employs advanced inverter control technology to ensure high accuracy in determining the length of the paper core. This eliminates manual errors and guarantees consistent quality in every production cycle.

2. Automated Online Processing

This integrated process minimizes human intervention, reduces labor costs, and enhances overall efficiency.

3. Customizable Product Dimensions

Both the diameter and length of the paper core can be tailored to meet specific customer requirements. Whether for industrial or commercial use, this flexibility allows for diverse applications across various sectors.

4. Wide-ranging Industrial Applications

The produced paper tubes are extensively utilized in multiple industries, including toilet paper manufacturing, plastic packaging, and textile production. Their durability and adaptability make them ideal for high-demand environments.

5. User-friendly Design and Maintenance

The machine is designed with practicality in mind, featuring an intuitive interface that simplifies operation. Additionally, its modular structure ensures easy maintenance, reducing downtime and prolonging the equipment’s lifespan.

|

speed |

15 ~ 20m / minutes |

|

Kraft paper width |

50-105 mm |

|

Paper Tube diameter |

45mm(Different diameters need change mold ) |

|

Paper tube layers |

2 ~ 6 layers |

|

Paper grams amount |

150-400 gsm |

|

Reel Length |

800-3000 mm |

|

Defect rate |

≤2% |

|

Power |

3.5KW 380V 50HZ 3Phase |

|

Equipment Size(L*W*H) |

main machine: 4550*1700*1800mm Glue buckets device: 1250*850*1200mm |

|

Weight |

1500Kg |

The high speed center pulling paper core roll making machine is used to produce the paper core inside toilet paper rolls. It comprises three main components:

1. a Kraft paper raw material stand

2. a glue unit

3. a rewinding and cutting unit.

By adjusting the model, it can manufacture paper cores in various thicknesses and diameters. This machine is easy to operate, runs stably, and can be integrated with a toilet paper rewinding machine

1. XY-TQ-B Automatic toilet paper rewinding machine Automatic Toilet Paper Rewinding Machine is designed for processing toilet paper rolls. The machine features a core feeding uni...

Main function and feature: 1. Enhanced Paper Feeding: A widened belt on the backstand increases friction during paper feeding for improved stability. 2. Precision Transmiss...

This production line consists of : 1. XY-TQ-B A utomatic color printing m axi ki tchen towel roll rewinding machine Feature and Function 1. Aut...

This kitchen towel machine exceeded expectations! good effect of kitchen towel made a huge difference, and the support team was helpful throughout the process2025-11-04

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04