![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-H

Model:

XY-TQ-A-H

![]() Power:

45KW 380V 50HZ 3Phase (Depends on the jumbo roll width)

Power:

45KW 380V 50HZ 3Phase (Depends on the jumbo roll width)

![]() Application:

maxi roll paper towel production line

Application:

maxi roll paper towel production line

![]() Weight:

10 tons (depends on the jumbo roll width)

Weight:

10 tons (depends on the jumbo roll width)

![]() Output:

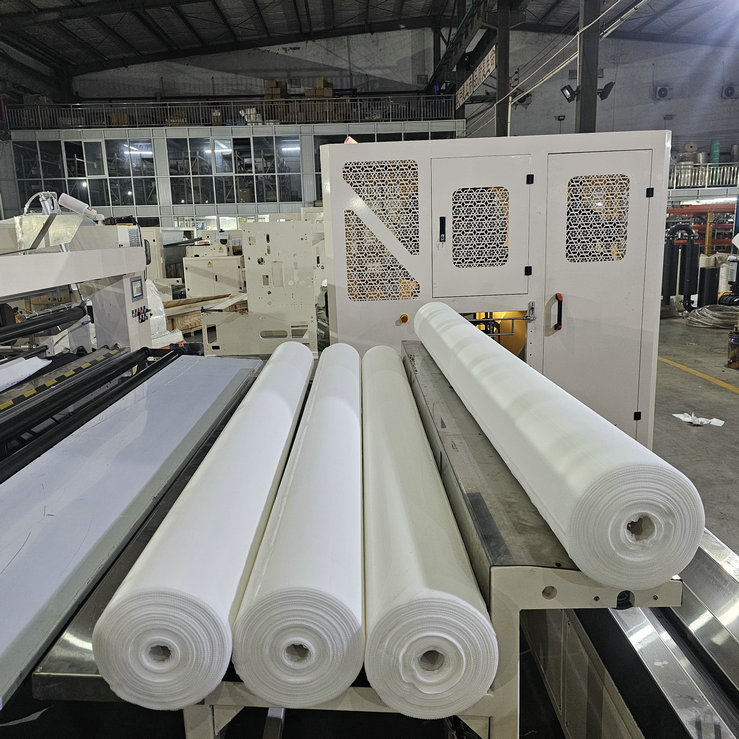

maxi roll paper

Output:

maxi roll paper

![]() Packaging Dimension:

12000*5800*2100mm(depends on the jumbo roll width)

Packaging Dimension:

12000*5800*2100mm(depends on the jumbo roll width)

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

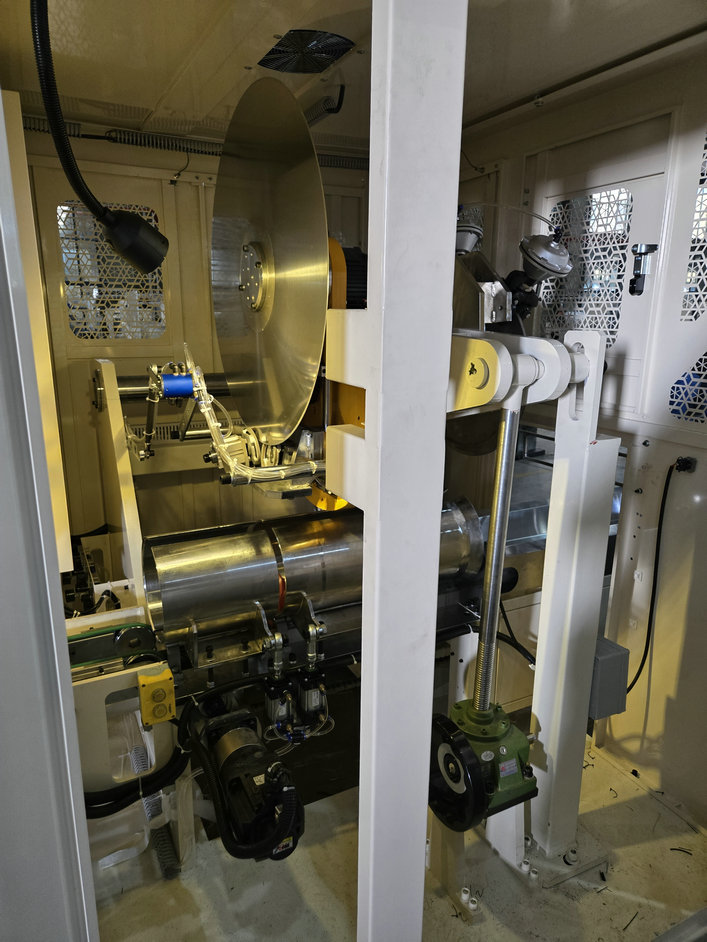

1. XY-TQ-B Automatic lamination maxi roll toilet paper rewinding machine

Technical data:

1. Production speed: 0-200-m /min

2. 1200-3000mm width of jumbo roll

20mm thickness of wall board of machine

3. Diameter of finished toilet paper: 90-300mm

4. Diameter of finished toilet paper inner core: 38-90mm

5. Perforation distance: 4 anvil Blades(90-140mm)

6. Power:25kw (380V 50Hz 3Phase)

7. Max. diameter of jumbo roll paper : 1200mm

8. Diameter of jumbo roll paper inner core: 76.2mm

9. Overall size(L*W*H): 6500*3800*2100mm

10. Weight : About 5-10T

11. Two sets paper standers (Individual motor to control the tension)

12. Individual motor for each jumbo roll stander, PLC control the tension of paper

13. HS code: 8441809000

2. XY-AI-280 High speed maxi roll log saw cutting machine

Technical parameter:

1. Cutting speed: 20-60cuts/minute

2. Cutting blade: log saw cutter(diameter 810mm)

3. Toilet log maxi length: 300mm

4. Finished toilet roll length: max. 250mm

5. Finished toilet roll diameter: 130-250mm(different diameter need change molds)

6. Cutting tolerance: ±1.5mm

7. Power supply: 20kw 380V 50Hz 3Phase

8. Overall size: 4800*1500*2100mm

9. Machine weight: 3000KG

This production line including 2 sets machine:

1. XY-TQ-B Automatic lamination maxi roll toilet paper rewinding machine

2. XY-AI-280 High speed maxi roll log saw cutting machine

These two machines automate the full production cycle from jumbo roll to maxi roll, integrating glue lamination, embossing, non-stop accumulator, perforating, rewinding, and log saw cutting. Computer servo control allows real-time precision adjustments for each cut's dimensions and net edges.

Model cutting and sealing machine temperature shrink machine Power source 220V 50Hz/60Hz 380V 50/60Hz Rated Power 1.35KW ...

Main function and feature: 1. Enhanced Paper Feeding: A widened belt on the backstand increases friction during paper feeding for improved stability. 2. Precision Transmiss...

This production line consists of : 1. XY-TQ-B A utomatic color printing m axi ki tchen towel roll rewinding machine Feature and Function 1. Aut...

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04