![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-XX-A

Model:

XY-XX-A

![]() Power:

18KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

18KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

jumbo roll tissue rewinding and slitting machine

Application:

jumbo roll tissue rewinding and slitting machine

![]() Weight:

5 tons (depends on the jumbo roll width)

Weight:

5 tons (depends on the jumbo roll width)

![]() Output:

Jumbo roll tissue paper

Output:

Jumbo roll tissue paper

![]() Packaging Dimension:

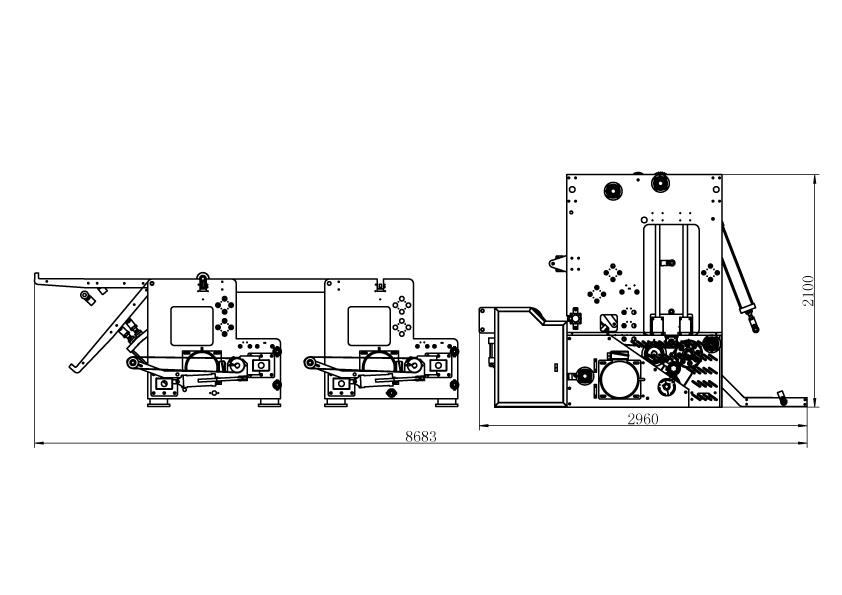

8683*3000*2000mm

Packaging Dimension:

8683*3000*2000mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Main function and feature:

1. Enhanced Paper Feeding: A widened belt on the backstand increases friction during paper feeding for improved stability.

2. Precision Transmission: Synchronous belt drive ensures smooth operation with minimal noise, even at high speeds.

3. Adjustability: The newly designed fastening unit allows convenient raw material adjustment.

4. Advanced Loading System: Features pneumatic paper loading with edge vacuum suction for precise handling.

5. Automated Discharge (Optional): Automatic finished roll discharge prevents deformation caused by paper falls and reduces labor requirements.

6. User-Friendly Operation: Simple controls produce consistently well-wound rolls with clean cutting edges.

Technical parameter:

1. Raw material width : 2300 mm

2. Raw Material Diameter : 1200 m

3. Speed : 250-350 m/min

4. Finished products diameter : 1200 mm

5. Slitting width : Adjustable(Minimum width as 200mm)

6. Finished products core diameter : 76.2 mm

7. Raw material core diameter : 76.2mm(Please specify other specifications)

8. Unwinding unit : 3 layer

9. Rewinding system : Pneumatic timing rewinder

10. Slitting system : Automatic slitting control

11. Discharging unit : Automatic discharging

12. Edge cutting unit : Vacuum suction edge cutting 2.2 KW

13. Power : Frequency conversion speed regulate 15KW

14. Pneumatic system : 3HP air compressor, min. pressure 5kg/cm2pa ( provide by user)

15. Dimensions(L x W x H)(mm) : 9500*3300*2300

16. Weight : About 5000 KG

The high-speed fully automatic jumbo roll slitting and rewinding machine is a high-speed slitting system that processes jumbo roll. It can slitting and rewinding single-ply jumo roll into two, three, or four-ply jumbo roll paper with various widths, suitable for producing napkins paper, handkerchiefs paper, facial tissues, or toilet paper. The machine features excellent performance, a compact structure, stable operation, and user-friendly controls. The finished products exhibit superior winding profiles, making it ideal equipment for paper mills and textile factories, earning high customer satisfaction

1. XY-TQ-B Automatic toilet paper rewinding machine Automatic Toilet Paper Rewinding Machine is designed for processing toilet paper rolls. The machine features a core feeding uni...

Model cutting and sealing machine temperature shrink machine Power source 220V 50Hz/60Hz 380V 50/60Hz Rated Power 1.35KW ...

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02

Finally, no more bulky store trips! The machine delivers consistent quality—soft, absorbent, and durable. Packaging is minimal and recyclable2026-01-26