![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-D

Model:

XY-TQ-A-D

![]() Power:

40KW 380V 50HZ 3Phase

Power:

40KW 380V 50HZ 3Phase

![]() Application:

10 rolls Toilet paper production line

Application:

10 rolls Toilet paper production line

![]() Weight:

8 tons (depends on the jumbo roll width)

Weight:

8 tons (depends on the jumbo roll width)

![]() Output:

10 rolls bundle toilet paper

Output:

10 rolls bundle toilet paper

![]() Packaging Dimension:

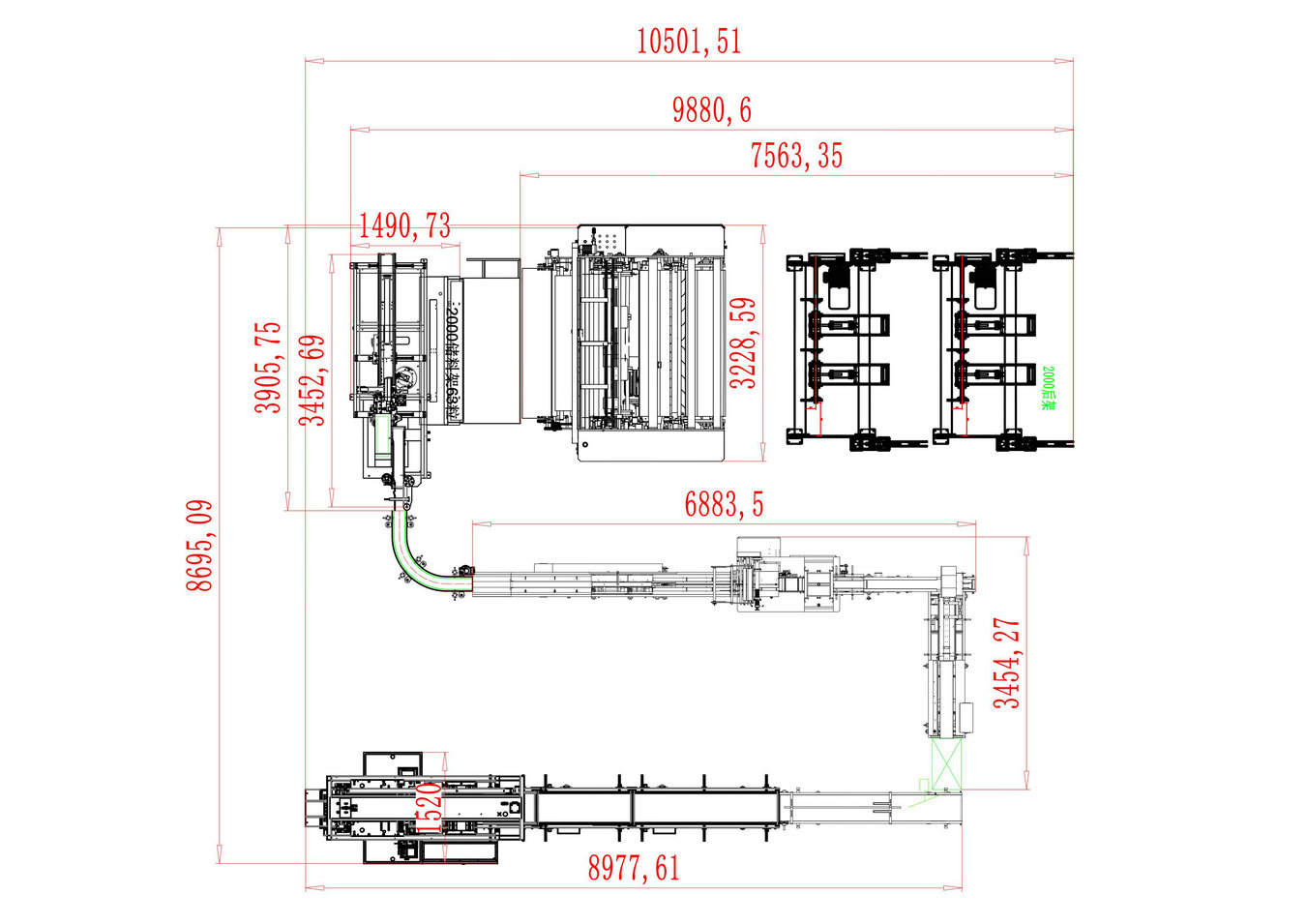

10500*8700*2200mm

Packaging Dimension:

10500*8700*2200mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

1. XY-TQ-B Automatic toilet paper rewinding machine

Automatic Toilet Paper Rewinding Machine is designed for processing toilet paper rolls. The machine features a core feeding unit and can handle both core and coreless operations.

The raw material, from a jumbo roll, undergoes full or edge embossing, followed by perforation, end cutting, and tail gluing to form a log. It can then be integrated with cutting and packing machines to produce finished products.

Controlled by a PLC and operated via a touch screen, the entire process is fully automatic, easy to operate, and significantly reduces labor costs. Additionally, our machines can be custom-made to meet specific client requirements.

Production Process: Unreeling — Embossing — Perforating — Rewinding — Tail-gluing — Edge trimming — Automatic core loading.

2. XY-AI-400 Automatic toilet paper cutting machine

This equipment is the company's latest independently developed model, designed in line with current market demands. It features PLC programming control, a large-screen color HMI for operation, precise servo-controlled feeding length, and other internationally advanced mechatronic technologies. The system automatically monitors all key operations and includes a comprehensive fault information prompt system, ensuring the entire production line operates at optimal efficiency.

3. XY-503IZ Automatic single roll toilet paper packing machine

This single-roll paper automatic packing machine is designed for single toilet paper rolls (with or without core) and kitchen tissue, offering fully automatic packing. It features servo-driven operations for paper feeding, film feeding, longitudinal sealing, cutting, coreless paper exhaust, and reversing. With a complete run function configuration, it delivers high efficiency, simple operation, wide specification adaptability, quick changeover, and convenient maintenance, ensuring low operating costs.

4. XY-AI-398D Automatic 10 rolls toilet paper bundle packing machine

◆ Compatibility:

Connects with an automatic paper cutter (band saw or log saw).

Integrates with single toilet paper wrapping machine.

◆ Control System:

Servo-driven with PLC control.

◆ Automation Features:

Auto-feeding and auto-adjustment with high-quality sensors.

Operated via a color touchscreen display.

◆ Safety & Protection:

Emergency stop/pause function, safety alarm system, and air/electric power protection.

◆ Sealing & Cutting:

Equipped with a constant-temperature sealing and cutting system.

1. XY-TQ-B Automatic toilet paper rewinding machine

Technical parameter:

1. Production speed: 200-230 m /min

2. Power:15kw (380V 50Hz 3Phase)

3. Max. diameter of jumbo roll paper : 1200mm, jumbo roll width 1850mm

4. Diameter of jumbo roll paper inner core: 76.2mm

5. 1850mm width of jumbo roll.

6. Weight : About 4T

7. Two sets paper standers (Individual motor to control the tension) and one sets of steel to rubber embossing roll for toilet paper

8. 20mm thickness of wall board of machine

9. Diameter of finished toilet paper: 90-300mm

10. Diameter of finished toilet paper inner core: 38-76mm

11. Perforation distance: 4 anvil Blades(90-135mm)

12. Overall size(L*W*H): 6500*2800*2100mm

13. Individual motor for each jumbo roll stander, PLC control the tension of paper

2. XY-AI-400 Automatic toilet paper cutting machine

Technical parameter:

1. Cutting speed: 80-100cuts/minute

2. Cutting blade: band saw blade(Size 3750*60*0.6)

3. Toilet log length: max 2850mm

4. Finished toilet roll length: max. 250mm

5. Finished toilet roll diameter: 90-120mm

6. Cutting tolerance: ±1.5mm

7. Power supply: 7.5kw 380V 60Hz 3Phase

8. Overall size: 2800*1500*2100mm

9. Machine weight: 1100KG

3. XY-503IZ Automatic single roll toilet paper packing machine

Technology Parameter:

1. Speed: 150-200 pack/min

2. Diameter of finished products: 90-120mm

3. Length of finished products: 80-200mm

4. Max width of film(mm): 430

5. Power: 15.5KW 380V 50HZ 3Phase

6.Material of film: BOPP,SPP,CPP(as usual, use CPP)

7. Overall Dimension: 5500*3300*1600 mm

8. Weight: 1800KG

4. XY-AI-398D Automatic 10 rolls toilet paper bundle packing machine

Technology Parameter:

1. Speed: 10-18 bags/min

2. Diameter of finished products: 90-120mm

3. Length of finished products: 100-120mm

4. Height: of finished products: 100mm

5. Package type: 8rolls, 10rolls and 12rolls in one layer

6. Packing size: L(200-700)*W(180-260)*H(90-140) mm

7. Voltage: 10KW 380V 50HZ 3Phase

8. Packing material:PE, thickness::≥0.05mm

9. Overall Dimension: L6500*W1520*H1600 mm

10. Weight: 2000KG

This production line including 4 sets machine:

1. XY-TQ-B Automatic toilet paper rewinding machine

2. XY-AI-400 Automatic toilet paper cutting machine

3. XY-503IZ Automatic single roll toilet paper packing machine

4. XY-AI-398D Automatic 10 rolls toilet paper bundle packing machine

From jumbo roll paper into the small individual toilet paper roll, It’s best choice for the producing 10 rolls bundle toilet paper roll.

Features: 1. Multi-functionality: Servo-controlled operation with automatic conveying, feeding, sealing, and counting. 2. Advanced control system : Equipped with PL...

1. XY-TQ-B Automatic lamination toilet paper making machine Feature and Function 1. Automatic Core Feeding Rewinding System Features automated log pusher post-rew...

1. XY-TQ-B Automatic toilet paper rewinding machine Automatic Toilet Paper Rewinding Machine is designed for processing toilet paper rolls. The machine features a core feeding uni...

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02

they walked us through the installation and provided training. Highly recommend for manufacturers looking to scale up2025-11-04

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02