![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-A

Model:

XY-TQ-A-A

![]() Power:

55KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

55KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

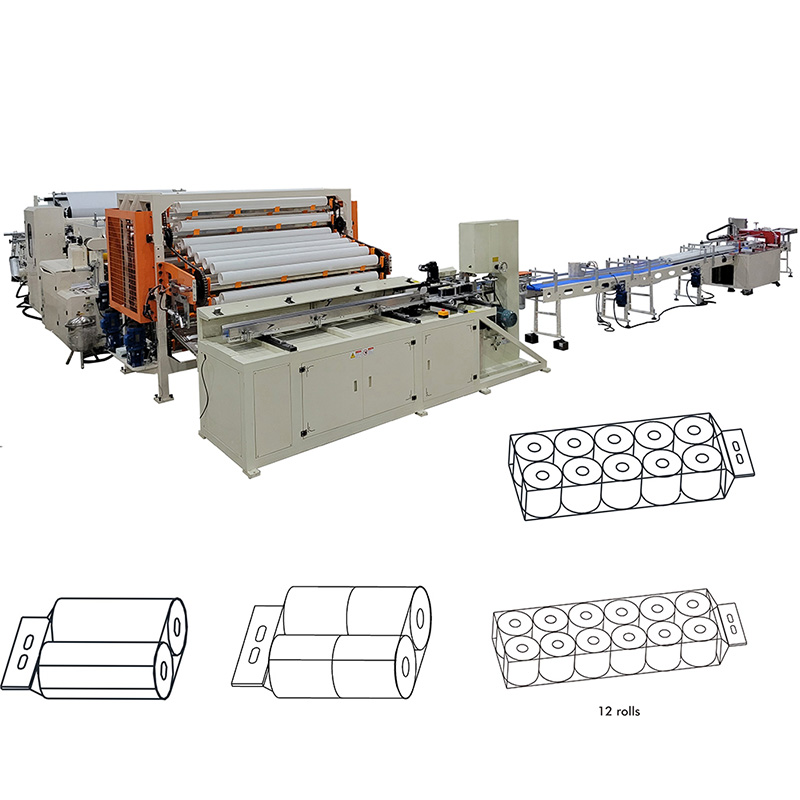

10 rolls lamination toilet paper roll making machine production line

Application:

10 rolls lamination toilet paper roll making machine production line

![]() Weight:

8 tons (depends on the jumbo roll width)

Weight:

8 tons (depends on the jumbo roll width)

![]() Output:

10 rolls package toilet paper roll

Output:

10 rolls package toilet paper roll

![]() Packaging Dimension:

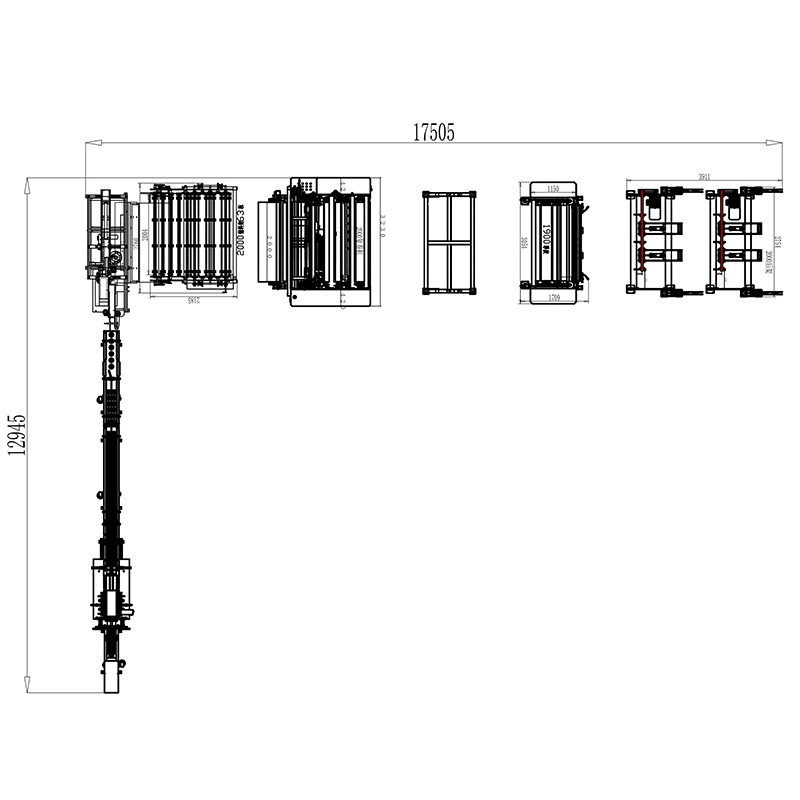

13000*17500*2200mm

Packaging Dimension:

13000*17500*2200mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

1. XY-TQ-B Automatic lamination toilet paper making machine

Feature and Function

1. Automatic Core Feeding & Rewinding System

2. XY-203 Log roll paper accumulator

Function: To make glue laminated toilet paper log roll dry before cutting and packing, so to get a better effect.

3. XY-AI-400 High speed small toilet paper lamination roll band saw Cutting Machine

1. When the paper cannot be trimmed, the equipment will automatically halt and trigger an alarm system.

2. A high-precision servo system is employed in the feed motor to guarantee the quality of the finished product.

3. The equipment automatically calculates the quantity of finished products based on raw material dimensions and target length.

4. In case of incorrect data input, the equipment will interrupt operation and prompt adjustment through the interface.

5. The equipment features automatic sorting for both waste paper heads and tails.

6. An automatic knife sharpening system is integrated, allowing adjustment according to the paper type being cut, thereby extending blade lifespan.

7. The sharpening system utilizes hardened steel wheels to significantly improve sharpening efficiency.

4. XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

1. Multi-functionality: Features automatic conveying, single-head operation, automated feeding, sealing, and counting.

2. Advanced Control System: Equipped with PLC-based computer programming and LCD parameter display for simplified operation. Incorporates water-cooling technology with precise temperature control to enhance protection of thermally stable heating wires and tapes. The servo-driven product push mechanism ensures accurate positioning.

3. High-Quality Packaging: Delivers neat packaging and sealing. Offers full/semi-automatic operation modes. Conveyor-compatible design enables integration with automatic toilet roll packing systems, maximizing efficiency while reducing labor costs.

4. Production Capacity: Processes 8-12 bundles per minute with single-labor operation.

5. Universal Compatibility: Suitable for both core and coreless toilet rolls.

6. Robust Construction: Built with a rigid frame and imported components for stable, high-efficiency operation and extended equipment lifespan.

1. XY-TQ-B Automatic lamination toilet paper making machine

Technical data:

1. Production speed: 200-230m /min

2. Power: 37.7kw (380V 50Hz 3Phase)

3. Diameter of rewinding : 90-300 mm

4. Overall size(mm):9000X2800X2100

5. Weight : About 7T

6. Two sets paper standers((Individual motor to control the tension)

7. 1850mm width of jumbo roll and max. Diameter 1200mm, inner diameter of paper core: 76.2mm

8. Perforation distance: 4 anvil Blades(90-140mm)

2. XY-203 Log roll paper accumulator

Technical data:

1.Log Width:2520mm

2.Log Diameter:Φ95mm~Φ130

3.Log Standings: 50Logs

4.Accumulate speed:20 logs/min

5.Log Qty: 30Logs

6.Dimensions:4000*3000*5500mm

3. XY-AI-400 High speed small toilet paper lamination roll band saw Cutting Machine

Technical parameter:

1. Cutting speed: 80-100cuts/minute

2. Cutting blade: band saw blade(Size 3750*60*0.6)

3. Toilet log length: 2850mm

4. Finished toilet roll length: max. 250mm

5. Finished toilet roll diameter: 90-120mm

6. Cutting tolerance: ±1.5mm

7. Power supply: 7.5kw 380V 50Hz 3Phase

8. Overall size: 2800*1500*2100mm

9. Machine weight: 1100KG

4. XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

Technology Parameter:

1. Speed: 5-10bags/min

2. Diameter of finished products: 90-120mm

3. Length of finished products: 100-120mm

4. Height: of finished products: 100mm

5. Package type: 6rolls, 8rolls and 10 rolls in one layer

6. Voltage: 3KW 380V 50HZ 3Phase

7. Overall Dimension: 8700*1000*1300 mm

8. Weight: 600KG

4. XY-AI-398A Semi automatic 10 rolls small toilet paper packing machine

Our good quality 10 rolls small lamination toilet paper roll making machine production line seamlessly converts jumbo paper rolls into high-quality small glue lamination toilet paper through an integrated conversion process.

Engineered for precision, the system delivers consistent performance across all stages—unwinding,glue lamination, embossing, perforating, and rewinding—with minimal downtime.

Equipped with advanced servo motors and PLC controls, it maintains optimal operational speeds while maximizing energy efficiency.

This intelligent automation reduces labor dependency by 60-70% compared to manual operations, significantly alleviating worker fatigue.

Designed for reliability and low maintenance, the line excels in producing premium kitchen towels and toilet paper with exceptional efficiency.

Its modular design enables swift adaptation to diverse product specifications, offering tissue paper manufacturers a cost-effective solution to boost productivity without compromising quality.

I. Intelligent Sharpening System 1. Equipped with an intelligent sharpening device (integrated with the human-machine interface): - Motor-driven grinding wheel 2. Three-dimensiona...

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine 2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine 3. XY-AI-398-B Pla...

This equipment is the latest model independently developed by the company in combination with the current market usage. The equipment adopts PLC programming control, large-screen tru...

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02