![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-H

Model:

XY-TQ-A-H

![]() Power:

60KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

60KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

Color printing maxi roll paper towel production line

Application:

Color printing maxi roll paper towel production line

![]() Weight:

10 tons (depends on the jumbo roll width)

Weight:

10 tons (depends on the jumbo roll width)

![]() Output:

Color printing maxi roll paper towel

Output:

Color printing maxi roll paper towel

![]() Packaging Dimension:

6500*2800*2100mm(depends on the jumbo roll width)

Packaging Dimension:

6500*2800*2100mm(depends on the jumbo roll width)

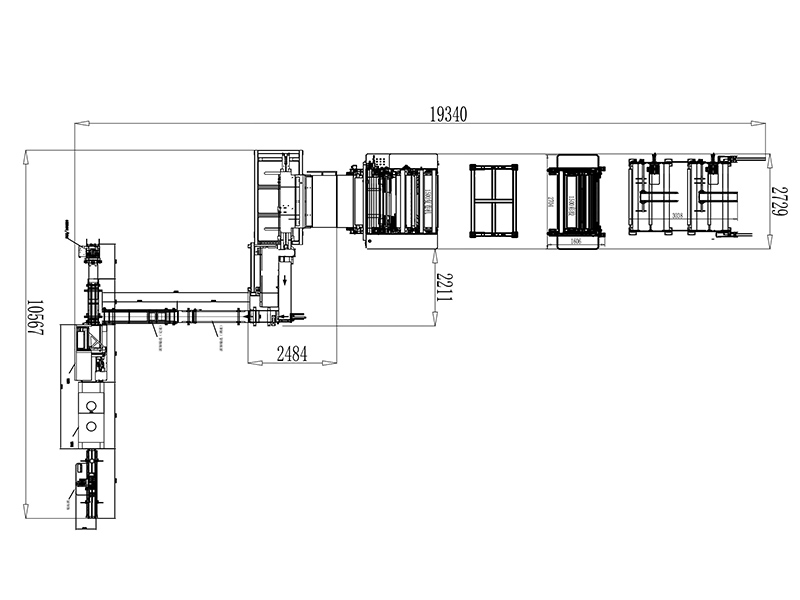

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

This production line consists of :

1. XY-TQ-B Automatic color printing maxi kitchen towel roll rewinding machine

Feature and Function

1. Automatic core feeding system, automatic log pusher after rewinding, then rewinding the new log again.

2. Automatic edge-trimming, core feeding, glue spraying and sealing synchronously in one time.

3.Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

4. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

6. Glue lamination Embossing Unit: adopt point to point embossing rollers, making the two layers lamination well, the finished product is fluffy and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

8.With two-color flexographic printing and precisely aligned patterns, the finished product is rich and colorful

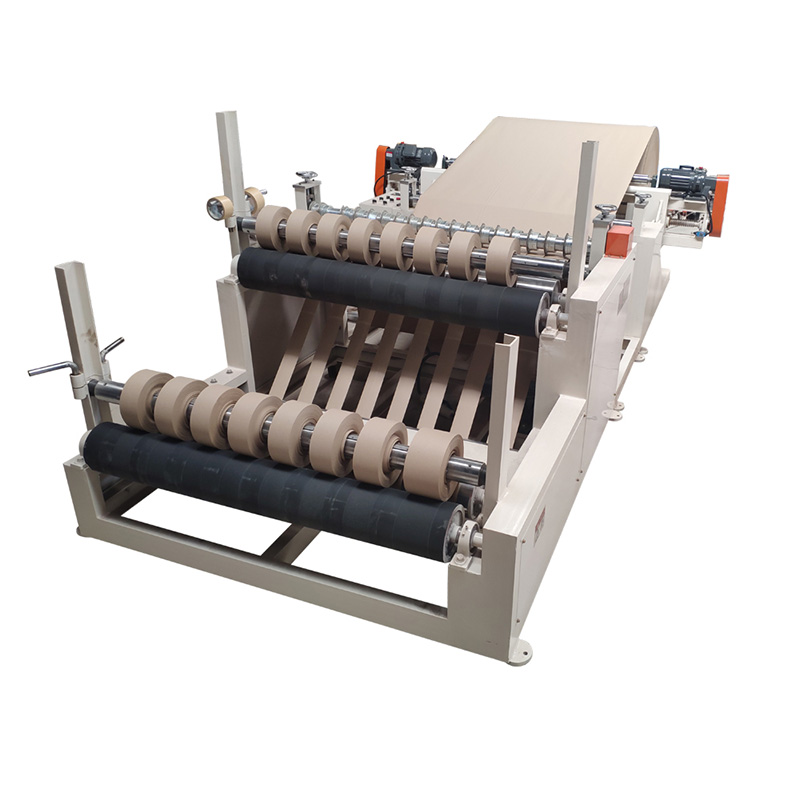

2. XY-AI-500 Automatic maxi roll band saw cutting machine

Feature and Function:

1.The main motor using the inverter independent drive.

2.For one set of machine, the cutting diameter of paper roll is adjustable as 150~250mm.

3.The equipment adopts automatic sharpening system, grinding wheel can be automatic feeding adjustment according to the blade loss.

4.The grinding system is equipped with an independent dust removal device to ensure the working environment.

5.The band saw adopts hydraulic tension system to ensure the tension of band saw.

6.It will be automatic stop and alarm when the knife is broken.

7.High precision servo system is used to ensure the quality of finished products.

8.According to the raw materials and the length of finished products, the number of finished products can be calculated automatically.

9.The device stops working and prompts the interface when the input data is wrong.

10.Using band saw for cutting and reduces the cost of use of users.

11.The thickness of finished paper core should less 3mm(Suggestion)

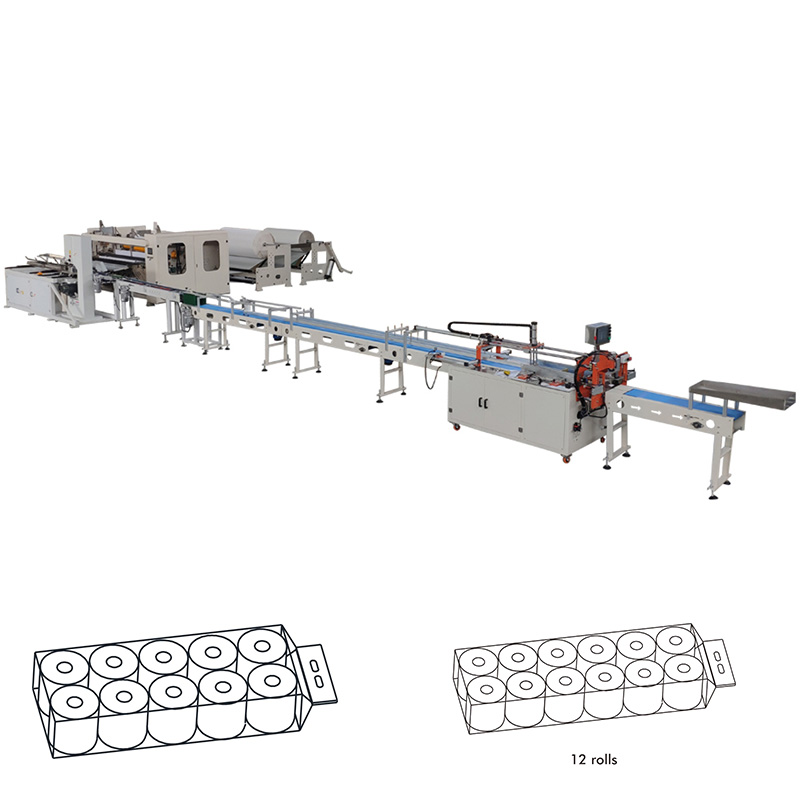

3. XY-TN-269 Automatic maxi roll labeling sealing and shrink wrapping machine

Feature and Function:

1. The automatic cutting, sealing, and temperature shrink machine is designed to wrap products in shrink film, which, after heating, tightly conforms to the item’s shape, creating a secure and visually appealing package.

2. This process not only enhances product protection against dust, moisture, and physical damage but also improves its presentation, adding a professional and premium aesthetic.

3. The shrink film evenly contracts around the product, ensuring a smooth, wrinkle-free finish that highlights the item’s design while reinforcing its durability.

4. This packaging solution is ideal for industries requiring both functional protection and elevated branding, such as food, cosmetics, electronics, and retail.

5. The automated system ensures consistency, efficiency, and high-quality results, making it a valuable asset for modern production lines.

4. XY-TN-600 Automatic Maxi Roll handle application machine

Equipment characteristics:

1. Large touch display screen, easy to operate, parameter display is clear at a glance, truly realizing human-computer dialogue.

2. Adopts Japanese Mitsubishi PLC control system, which is faster and has more stable performance.

3. Using Japanese Keyence photoelectric sensor for object detection, the sensitivity of sensing objects is higher.

4. Five-axis positioning label feeder, high labeling accuracy and better stability

5. The patented design of the bottom paper ensures that the paper will not be broken

6. Large-scale control box makes it easier to dissipate heat from internal electrical appliances, facilitates inspection, and increases robustness.

7. Made of high-quality stainless steel and aluminum alloy materials.

8. Humanized design, fewer faults and easy maintenance

9. The main components are precision processed by computer numerical control machine tools, and the mechanical movements are coordinated, stable and durable.

10. The surface of the aluminum alloy is treated with anodized sandblasting, which has higher strength and beautiful appearance.

11. The bottom of the equipment is equipped with casters and trumpet feet, which are convenient for both retention and support and easy movement.

12. Can be operated online or stand-alone.

Technical data:

1. Production speed: 200-230m /min

2. Power: 32kw (380V 50Hz 3Phase)

3. Diameter of rewinding : 90-280 mm

4. Overall size(mm):9000X2750X2100

5. Weight : About 12T

6. Two sets paper standers((Individual motor to control the tension)

7. 1850mm width of jumbo roll and max. Diameter 1200mm, inner diameter of paper core: 76.2mm

8. Perforation distance: 4 anvil Blades(90-140mm)

2. XY-AI-500 Automatic maxi roll band saw cutting machine

Technical parameter:

1. Cutting speed: 20-30 cuts/minute

2. Cutting blade: band saw blade(Size 5180*100*1.05)

3. Toilet log length: max 2800mm

4. Finished toilet roll diameter:150-280mm

5. Power supply: 15 kw 380V 50Hz 3Phase

6. Overall size: 5300*2350*2200mm

7. Machine weight: 2700KG

3. XY-TN-269 Automatic maxi roll labeling sealing and shrink wrapping machine

Technology Parameter:

1. Speed:18-25 rolls/min

2. Diameter of finished products: 150-250mm

3. Height of finished products: <300mm

4. Packing size: Width+ Height<650mm

5. Applicable film: POF folded film

6. Voltage: 380V 50HZ 3Phase

7. Overall Dimension: 4900*1450*1500 mm

8. Weight: 800KG

9. With labeling function

4. XY-TN-600 Automatic Maxi Roll handle application machine

Technology parameter:

1.Handle material: PET with sticker on both sides

2.Handle width: 20-50mm

3.Speed: 5-20 pcs /min

4.Roll film specifications: outer diameter<280mm, Paper core inner diameter 76mm, width<400mm

5.Power :0.75KW (220V 50HZ 1Phase)

7.Weight:800KG

8.Packing size: diameter and height 18-25cm

9. Air consumption: 60-100L/min

4. XY-TN-600 Automatic Maxi Roll handle application machine

Seamless Production Transformation: From Jumbo Roll to Premium Printed Maxi Rolls

The automated production line demonstrates exceptional efficiency in converting jumbo roll paper into high-quality 2-color printing maxi rolls with handle applications. Engineered for continuous operation, the system ensures:

Uninterrupted Workflow: Precision-fed rollers maintain consistent tension, eliminating paper jams and material waste.

Color Printing Excellence: Dual-color application achieves vibrant, smudge-free patterns with registration accuracy within ±0.5mm.

Labor Optimization: Fully automated cutting and embossing processes reduce manual intervention by 70%, significantly lowering production costs.

Stable Output: Advanced servo motors regulate speed fluctuations, sustaining a stable output of 800-1,200 rolls per hour.

This integrated solution not only enhances productivity but also guarantees ergonomic operation, making it the optimal choice for manufacturers seeking to balance efficiency with premium product quality.

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine 2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine 3. XY-AI-398-B Pla...

Type XY-AI-1092 XY-AI-1575 Slitting Width Adjustable Raw Material Size ≤φ1200*1100mm ≤φ1200*1700mm Production Speed ...

This production line including 3 machines: 1. XY-TQ-B High speed small toilet paper rewinding machine 2.XY-AI-400 Automatic toilet paper cutting machine 3.XY-AI-398A Semi automatic 1...

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04

they walked us through the installation and provided training. Highly recommend for manufacturers looking to scale up2025-11-04

the high-speed glue lamination toilet paper kitchen towel making machine offers smoother operation, faster production, and stronger, softer productsPerla 2025-09-02