![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-B

Model:

XY-TQ-B

![]() Power:

15KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

15KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

Toilet paper machine

Application:

Toilet paper machine

![]() Weight:

4 tons (depends on the jumbo roll width)

Weight:

4 tons (depends on the jumbo roll width)

![]() Output:

toilet paper

Output:

toilet paper

![]() Packaging Dimension:

6500*2800*2100mm(depends on the jumbo roll width)

Packaging Dimension:

6500*2800*2100mm(depends on the jumbo roll width)

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Good quality small toilet paper roll rewinding machine

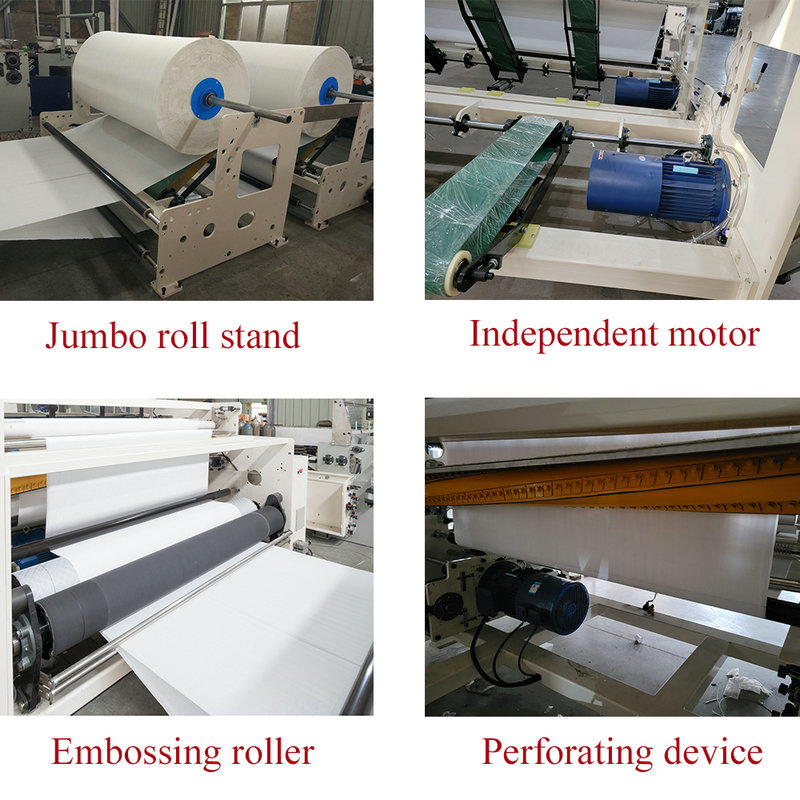

Features --- Wall Type Automatic Rewinding Machine

1.This machine is for making toilet paper rolls, the whole structure is wall-type, which make machine running stable at high speed, and noiseless.8. Adopt jogging switches for wearing the paper, easy and safe to operate.

Fujian Xinyun Machinery Development Co.,Ltd is good at Paper Converting Machinery Manufacture.

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-14 output lanes)

4) Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

|

Machine Model

|

XY-TQ-B

|

|

Jumbo Roll Max Width

|

2800mm (Other size can be specified)

|

|

Jumbo Roll Diameter

|

Φ1200mm(Other size can be specified)

|

|

Jumbo Roll Inner Diameter

|

3inches(76.2mm) (Other size can be specified)

|

|

Perforation Distance

|

4 anvil Blades(115mm)(Other size can be specified)

|

|

Finished Product Diameter

|

Φ90~φ300mm

|

|

Finished Product Core Diameter

|

φ38~φ90mm

|

|

Production Speed

|

200~230m/min

|

|

Program Controller

|

PLC( INVT )

|

|

Unwind Stands

|

2 Stands(Need to be specified)

|

|

Pneumatic System

|

3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user)

|

|

Main Power

|

14KW 380V 50HZ

|

|

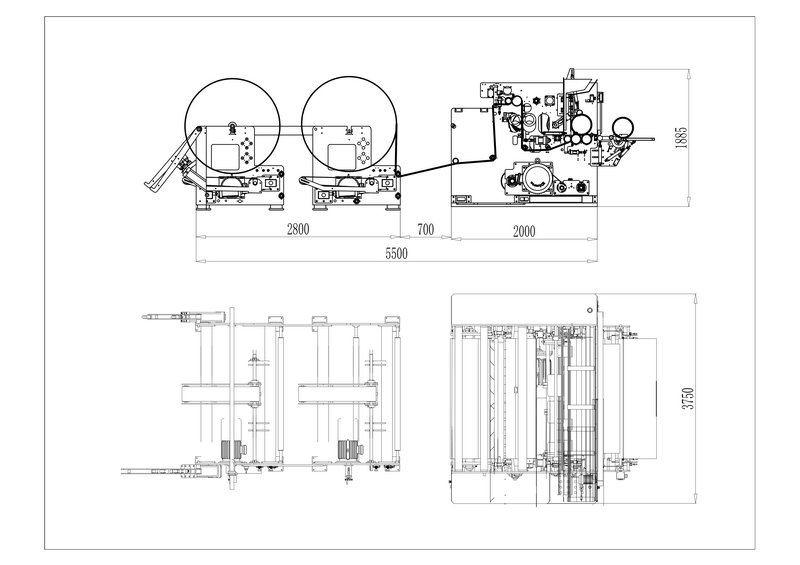

Dimension

|

7000*4000*1900(L*W*H)

|

|

Weight

|

About 7T

|

|

Edge-Line Embossing

|

Steel to steel (Pneumatic Control)

|

|

Full Embossment

|

Steel to rubber.

|

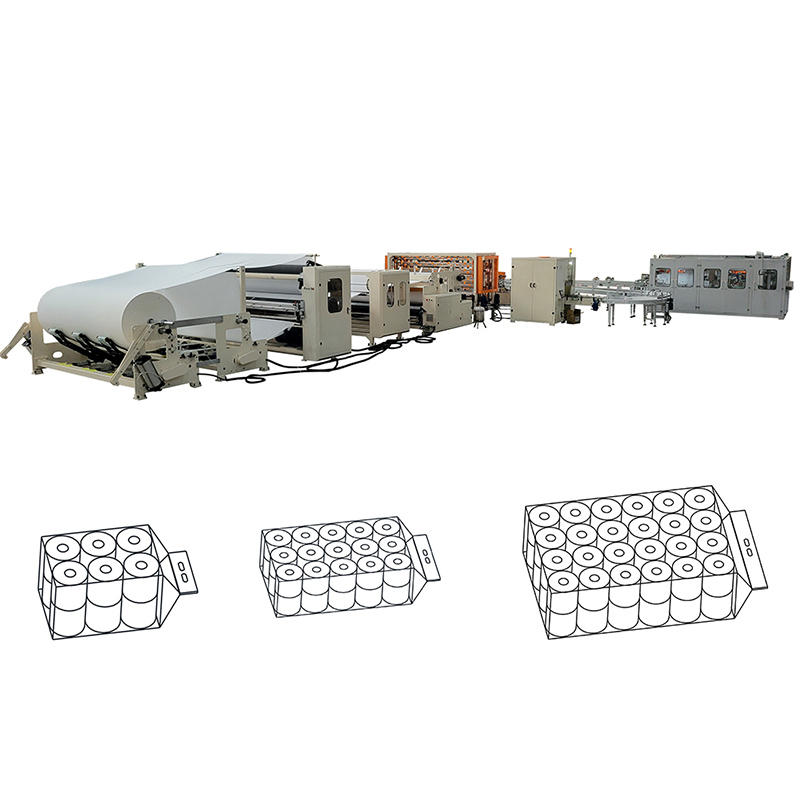

Automatic toilet paper rewinding machine is for toilet paper roll processing:

1. Machine have core feeding unit, can do both with and without core.

2. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log.

3. Then it can working with cutting machine and packing machine to become the finished products.

4. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost.

5. And Our machine can special-made according to clients’ requirements.

6. The production process is: Unreeling — Embossing — Perforating— Rewinding— Tail-gluing— Edge trimming

Function and Features: 1. Inflatable Shaft Winding : Ensures precise positioning of the paper tube, making alignment simple and accurate. 2. Edge Pressing System : ...

1. XY-TQ-B High speed small kitchen towel and toilet paper roll rewinding machine. 2. XY-203 Log roll paper accumulator. 3. XY-AI-280 Automatic kitchen paper and toilet roll log saw Cut...

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine 2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine 3. XY-AI-398-B Pla...

Reliable and durable, but the learning curve is steep. It took our team a few weeks to master the operate, but once we did,The machine is running smoothly and has high production efficiency.2025-11-04

The output maxi roll paper quality is consistent, and it’s worth the investment2025-11-04

Workers benefit from the good quality small toilet paper roll rewinding machine as it is easy to operate, safe,Adwan 2025-09-02

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04