![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-GU-281

Model:

XY-GU-281

![]() Power:

7KW 380V 50HZ 3Phase

Power:

7KW 380V 50HZ 3Phase

![]() Application:

Facial tissue cutting machine

Application:

Facial tissue cutting machine

![]() Weight:

1.6 tons

Weight:

1.6 tons

![]() Output:

facial tissue paper

Output:

facial tissue paper

![]() Packaging Dimension:

1600*1650*1700 mm

Packaging Dimension:

1600*1650*1700 mm

![]() Machine Size:

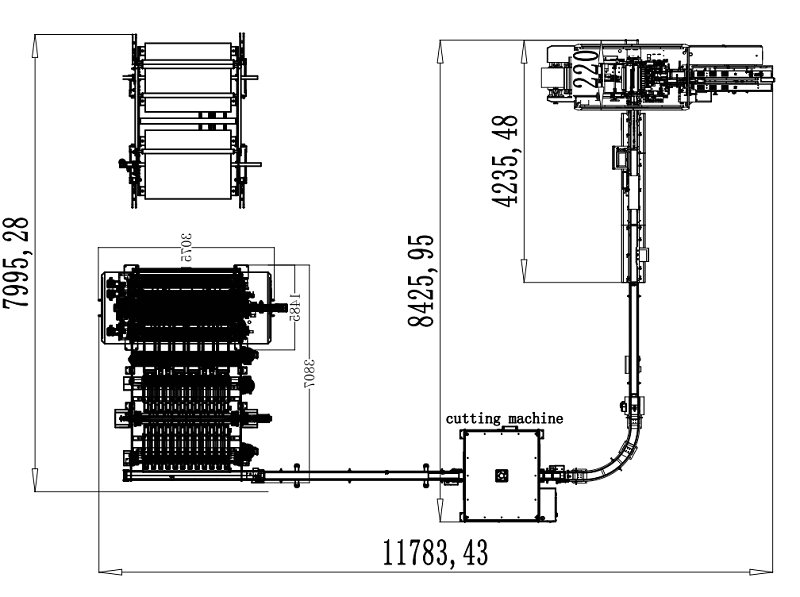

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Cyclotron paper cutter is used to automatically cut off a row folded and round roll paper towel products, such as the removable tissue or toilet roll paper. The whole machine adopts servo drive technology and frequency control of motor speed and enhance the stability of paper cutting, and improves the cutting precision of tissue and to cut off the end face flat . Cutting length within the scope of the machine allows arbitrary adjustable. Fixed automatic knife grinding wheel Angle, ensure the quality of the sharpening knife. Knife grinding place often blow compressed air for cooling, and can match the special cooling fluid.

Main technical parameters

|

Designation |

Parameter values |

|

The length of unfinished products |

minimum 500mm(or, mini 5lines) |

|

The Height of finished product |

30~120mm |

|

Production Speed |

20~150cuts/min |

|

Operating speed |

20~120cut/min |

|

Round blade outer diameter |

Φ610mm |

|

Paper cutting circular knife top speed |

980R/min |

|

Finished products specification |

70~210mm |

|

Paper width |

70~110mm |

|

Cutting Length |

70~210mm |

|

Left-over Length |

20~65mm |

|

Power |

7KW |

|

Power supply |

380V 50Hz |

|

Air pressure |

0.5~0.8MPa |

|

Machine Size |

1600*1650*1700 mm |

|

weight |

1500kg |

|

brake |

Parameter setting (auto/manual) |

|

Stepping sharpening knife |

Parameter setting (auto) |

|

Pneumatic sharpening knife |

Parameter setting (auto/manual) |

|

Blow air |

without |

|

The total pressure switch |

Value (not) |

|

Human-computer interface |

DELTA (or selected by customer) |

|

frequency changer |

DELTA |

|

Servo Drive |

DELTA |

After Sales Service

(1), All our machine will have Two years guarantee

(2), Within two year after receiving our machines, Under right operation and non-artificial reasons, If there are any damaged parts or accessories, We will replace them by DHL or Fedex immediately FREE OF CHARGE.

(3), After two year warranty, Spare parts and damaged parts will be charged at cost price. If there is something wrong with the machine, We are responsible to solve this problem soonest, and help customers to restore production as soon as possible.

(4), After the machines arrive, the sellers shall send technician to install the production line(if need). And the buyer shall pay their round-trip air tickets from China factory to buyer's factory, the charge of visa, food ,transportations and accommodation in buyer's city.

|

Cutting size |

Length |

90-210mm |

|

|

Width |

80-110mm |

|

|

Height |

25-120mm |

|

Cutting Speed |

200-260 cuts/minute (the cutting speed varies according to the length of cutting) |

|

|

Control system |

PLC program control |

|

|

|

servo drive |

|

|

|

touch screen operation |

|

|

Feeding method |

servo drive |

|

|

|

synchronous belt positioning and transmission |

|

|

Cutting off method |

360° rotational movement continuous |

|

|

Paper cutting accuracy |

cutting error ±1mm |

|

|

Knife sharpening system |

automatic sharpening |

|

|

|

touch screen parameter setting |

|

|

Outer diameter of paper cutter |

¢610mm |

|

|

Required air pressure |

0.5Mpa (prepared by the buyer)

|

|

|

Power |

7KW, 380V/50Hz |

|

|

Machine Size(L*W*H) |

1600*1650*1700 mm |

|

|

Weight |

1.5 tons |

|

|

Equipment color |

milky white paint spraying process |

|

1. Cut off the paper head and paper tail system: PLC program control and touch screen operation are completed.The length after removing the head and tail is 15mm---25mm

2. The paper output electric eye detection system of the equipment, including packaging machines and conveyors, will automatically shut down the cutting machine when a fault occurs and the products are accumulated.

3. Motor inverter control, energy saving, inverter Delta or Inovance brand,

4. The equipment control console is a touch screen, and the panel is made of stainless steel engraving.

5. The equipment electrical control box is integrated with the host to ensure that the circuit is not damaged and safe.

6. The equipment safety cover has a built-in iron mesh and plexiglass for external observation, which has safety protection functions.

Cyclotron paper cutter is used to automatically cut off a row folded and round roll paper towel products, such as the removable tissue or toilet roll paper. The whole machine adopts ser...

1. XY-GU-20A Automatic Transfer Facial Tissue Folding Machine 2. XY-GU-281 High Speed Facial Tissue Cutting Machine 3. XY-BT-298 Automatic Facial Tissue Bag Packing Machine 4.XY-GU-388...

1. XY-GU-20A Automatic transfer Hang Style Facial T issue Folding Machine 2. XY-GU-281 Automatic Hang Style Facial Tissue Log Saw Cutting Machine 3. XY-BT-299 Au...

XY-AI-398A 12rolls single layer bathroom toilet paper packing machine Functions and Features: This machine is specially used for packaging toilet paper roll, with a conveyo...

XY-TQ-1575B FullyAutomatic Toilet Paper Roll and Kitchen Towel Rewinding Machine 1.Automatic corefeeding system, automatic log pusher after rewinding, then rewinding the newlog ag...

XY-AI-398A Best price toilet tissue paper packaging machine Functions and Features: 1.Thismachineisspeciallyusedforpackagingtoilet paper roll,withaconveyorbelt. 2.Themachine...

The Automatic Facial Tissue Cutting Machine provides smooth operation, precise cutting, and consistent size. and delivers a reliable, user-friendly experience.Cesar 2025-09-02

The facial tissue machine touchscreen interface is user-friendly, and the energy-saving mode reduces costs by 10%. Worth every penny for startups in the paper product industry.2025-11-04

The Facial Tissue Machine offers high efficiency, stable performance, and easy operation, and supports energy-saving production with reliable output.Wei 2025-09-02

Perfect for our eco-friendly facial tissue packaging line! The machine produces soft facial tissue paper with minimal downtime2025-11-04