![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-GU-A-A

Model:

XY-GU-A-A

![]() Power:

55KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

55KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

Carton box and plastic bag facial tissue paper making machine

Application:

Carton box and plastic bag facial tissue paper making machine

![]() Weight:

8 tons

Weight:

8 tons

![]() Output:

carton box and plastic bag facial tissue

Output:

carton box and plastic bag facial tissue

![]() Packaging Dimension:

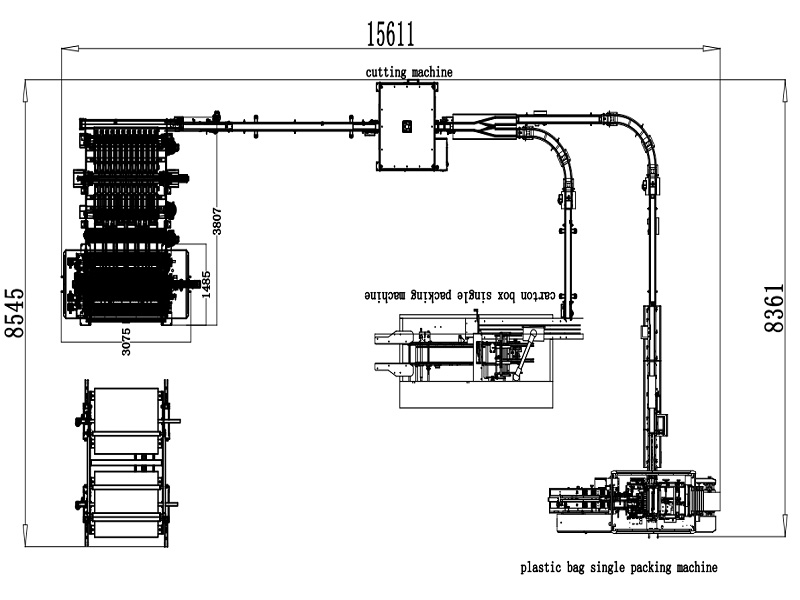

15641*8545*2100mm

Packaging Dimension:

15641*8545*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

1. XY-GU-20A Automatic Transfer Facial Tissue Folding Machine

Feature and Functions:

The paper-breaking knife roller is designed with a spiral blade structure, effectively addressing two critical challenges: stable paper breaking and extended blade lifespan.

Compared to the traditional straight-knife design, which often led to inconsistent paper cutting and premature blade wear, the spiral configuration ensures point-cutting precision.

This innovation not only enhances operational stability but also significantly prolongs the durability of the blades, making it a superior solution for high-efficiency paper processing.

Configuration:

A production line includes the following parts:

|

No. |

Description |

QTY |

unit |

|

1 |

unwind stand |

2 |

set |

|

2 |

folding device |

1 |

set |

1.Air source system: the air source is prepared by the buyer, and the air source access point is connected to a point which is 1-2 meters away from the gas point and equipped with a shut-off valve, which is according to the seller's requirements. The required pressure of the air source: 5-6kg/cm².

2.Power system: the power supply is prepared by the buyer, and the power supply is connected to the electrical control cabinet of the contract machine according to the seller's requirements.

3. Vacuum system: The piping required for vacuum connection is prepared by the buyer.

The high-speed facial tissue cutting machine is a critical component of box-drawing and bag-drawing facial tissue production lines, significantly enhancing automation levels and overall production efficiency.

Engineered for precision and durability, the machine features:

By integrating advanced cutting technology, this machine not only minimizes material waste but also optimizes workflow speed, making it an indispensable asset for high-volume tissue manufacturing.

3. XY-BT-298 Automatic Facial Tissue Bag Packing Machine

Compact Wrapping Design – Utilizes a hemming and sealing packing method with a streamlined structure, ensuring high product appeal and secure packaging.

Advanced Control System – Equipped with step-less frequency conversion, touchscreen interface, and PLC control for clear operation display and easy maintenance.

Automatic Conveyor Integration – Features an auto-loading conveyor that seamlessly connects with automated production lines, reducing labor costs and improving workflow efficiency.

Precision Speed Regulation – Incorporates dual transducer stepless-speed adjustment, automatically optimizing packing film length for consistent performance.

High Automation & Reliability – Delivers high automation, specialization, and efficiency with minimal downtime, ensuring smooth operations.

Quick Size Changeover – Designed with a fast and simple adjustment system, allowing easy handling of different product sizes without production delays.

4.XY-GU-388 Automatic carton box facial tissue packing machine

Automatic Rejection System - Detects and rejects products that are missing, have non-standard height, or lack required leaflets.

Carton Positioning Protection - Automatically stops operation when products are improperly positioned in cartons.

Material Monitoring System - Halts production when cartons are missing or leaflets run out continuously.

Quick Changeover Design - Easily adaptable for different product specifications with minimal setup time.

Overload Protection - Built-in safety mechanism to prevent equipment damage during peak loads.

Production Monitoring Display - Shows real-time production speed and finished product count for operational tracking.

1. XY-GU-20A Automatic Transfer Facial Tissue Folding Machine

Technical parameter:

1.Production speed:800-1000 sheets/lines/min

2.Product unfold size(L*W):200*200mm

3.Product folded size(L*W):100*200mm

4.Power: 35.3KW (380V 50Hz 3Phase)

5.Overall size(L*W*H):8500*2250*2000mm

6.Weight:about 5T

7.Size of jumbo roll: width:1440mm, diameter:1200mm

8.Weight of raw paper: Pure wood pulp (14-18)*2gsm

9. Roots blower

10. Individual motor to control jumbo roll

11. Steel to flat edge embossing device

2. XY-GU-281 High Speed Facial Tissue Cutting Machine

Technician parameter:

1. Production speed: 80-100 cuts/min

2. Cutting size: height: 20-120mm

width: 80-120mm

Length: setting freely

3. Power: 13.5Kw 380V 50 Hz 3 phase

4. Overall size: 1700*1500*2000mm(L*W*H)

5. Weight: 2.8T

6. HS code: 8441100000

3. XY-BT-298 Automatic Facial Tissue Bag Packing Machine

Technical Parameters:

1. Speed: 60-80 bags /min

Packing size(L*W*H):200*100*100mm

2. Used Shrink Film: CPP film

3. Power:11 Kw (380V 50Hz 3 phase)

4. Overall size of machine(L*W*H): 4650*3650*1800 mm

5. Weight:3T

6. HS code: 8422309090

4.XY-GU-388 Automatic carton box facial tissue packing machine

Technology Parameter:

1. Packing speed: 50-80boxes/min

2. Package size(L*W*H): 200*100*100mm

3. Power: 15KW (380V 50HZ 3Phase)

4. Overall dimension(L*W*H): 3400*1400*1700mm

5. Weight: 2000KG

This production line consists of :

1. XY-GU-20A Automatic Transfer Facial Tissue Folding Machine

2. XY-GU-281 High Speed Facial Tissue Cutting Machine

3. XY-BT-298 Automatic Facial Tissue Bag Packing Machine

4.XY-GU-388 Automatic carton box facial tissue packing machine

From the initial stage of processing jumbo roll paper to the final production of the carton box facial tissue and plastic bag facial tissue, the entire production line operates smoothly and maintains stable performance. This streamlined workflow significantly reduces labor costs by minimizing manual intervention and alleviates the physical strain on workers. The system is particularly well-suited for manufacturing carton box facial tissue and plastic bag facial tissue, offering efficiency and reliability. Its automated design ensures consistent quality while optimizing resource utilization, making it the ideal choice for businesses seeking cost-effective and high-output solutions in the tissue production industry.

1. XY-GU-20A Automatic Transfer Facial Tissue Folding Machine 2. XY-GU-281 High Speed Facial Tissue Cutting Machine 3. XY-BT-298 Automatic Facial Tissue Bag Packing Machine 4.XY-GU-388...

1. XY-GU-20A Automatic transfer V fold facial tissue folding machine 2. XY-GU-281 High speed facial tissue cutting machine 3...

1. XY-GU-20A Automatic transfer Hang Style Facial T issue Folding Machine 2. XY-GU-281 Automatic Hang Style Facial Tissue Log Saw Cutting Machine 3. XY-BT-299 Au...

XY-AI-500 280mm diameter JRT maxi roll paper cutting machine Features: 1.The main motor using the inverter independent drive. 2 For one set ofmachine, the cutting diameter ofp...

XY-AI-400 Auto small toilet tissue paper roll cutting machine for sale Technical performance characteristic : 1.The equipment is operated by using PLC program control, big...

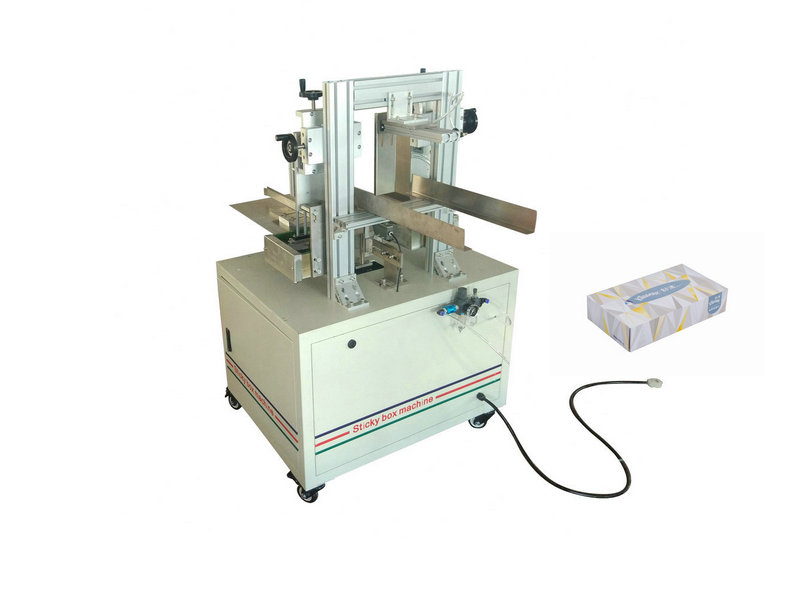

XY-TN-116 Box drawing facial tissue paper wrapping machine Semi automatic pasting machine with hot melt glue is one of the series of sealing boxes developed by our company, ...

Perfect for our eco-friendly facial tissue packaging line! The machine produces soft facial tissue paper with minimal downtime2025-11-04

The Automatic Facial Tissue Cutting Machine provides smooth operation, precise cutting, and consistent size. and delivers a reliable, user-friendly experience.Cesar 2025-09-02

The facial tissue machine touchscreen interface is user-friendly, and the energy-saving mode reduces costs by 10%. Worth every penny for startups in the paper product industry.2025-11-04

The Facial Tissue Machine offers high efficiency, stable performance, and easy operation, and supports energy-saving production with reliable output.Wei 2025-09-02