- How to operate color printing device of napkin tissue machine→

- How to produce napkin paper?→

![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-OQ-7000A

Model:

XY-OQ-7000A

![]() Power:

7.5KW 380V 50HZ 3Phase

Power:

7.5KW 380V 50HZ 3Phase

![]() Application:

Napkin paper folding machine

Application:

Napkin paper folding machine

![]() Weight:

1.5 tons

Weight:

1.5 tons

![]() Output:

napkin paper

Output:

napkin paper

![]() Packaging Dimension:

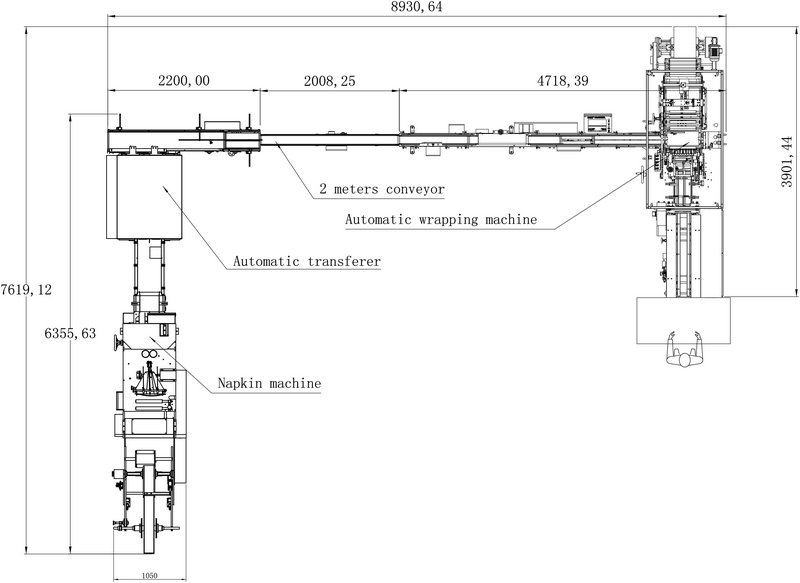

6355*1000*1800mm

Packaging Dimension:

6355*1000*1800mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

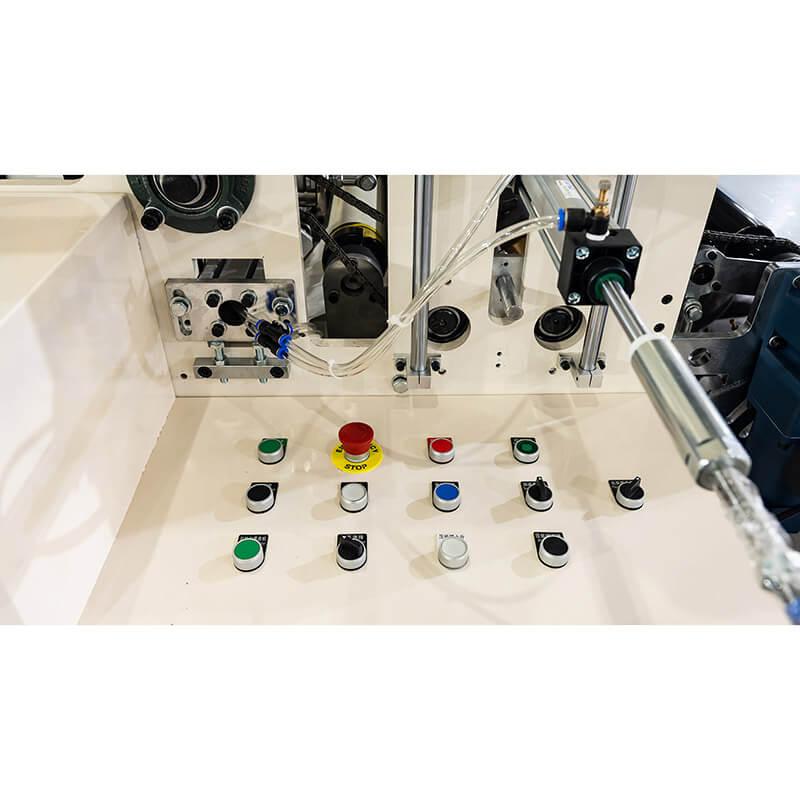

The Automatic Paper Napkin Machines are efficient, reliable and easy to operate machines. The high speed paper folder is quite useful for those who deal in supplying big quantities,it’s automatic Folding, Embossing, Embossing and Glue lamination (option), Color printing(Option) and Automatic transferring

Technical Parameters:

2.Finished product size: Open size:300 * 300 mm

3.Layers of the paper: 1-2 layers 15 - 21 g/ m², 1 layer paper need ≥19g

4.Raw materials for maximum width:300mm

5.Material Diameter:1200mm

6.Inner diameter of raw paper core: Φ76.2mm

7.Embossing: one set steel to paper

8.Calender: NO(could be customized)

9. Color printing device:2 color, ceramic anilox roll,sealed ink box

10.Folding Type:1/4

11. The host structure: wallboard structure.

12. The host drive: synchronous toothed belt drive, a flat belt conveying.

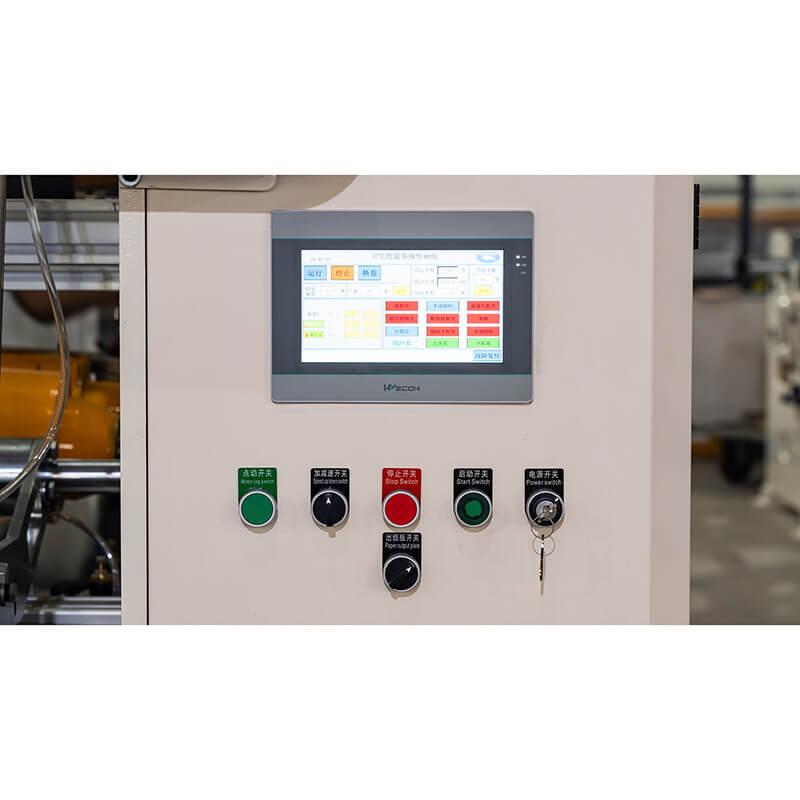

13. The control mode: frequency control of motor speed

14. The host power: 4 KW

15. Cutter power: 0.75 KW

16. Control electrical appliances: Siemens

17. Broken paper features: embossed cut paper stop position

18. Whet knife way: position manual adjustment, the pneumatic;

19. web guide: have

20. Counting: electronic counter, pneumatic hop

21. Operating speed:1200pcs/min

22. Working speed:1000pcs/min, according to the ink drying conditions is required for a print

23. Rear frame feeding: Automatic feeding,Type wide belf feeding, 1.2 meters in diameter can be put on the raw material

24. Power: 380V,three-phase four wire. Add ground

25. Automatic transfer function: using Siemens PLC program control and electronic pneumatic folding

26.Principle of automatic transfer: the directional distribution, collection and counting position location points fold pattern

27.Automatic transfer setting: Automatic transfer number adjustable, height between 35mm-120mm

|

Unfold size of finished products |

300*300mm |

|

Folded size of finished products |

150*150mm |

|

Diameter of jumbo roll paper |

1200 mm |

|

Diameter of jumbo roll inner core |

76.2 mm |

|

Production speed |

1000 pieces/min |

|

Embossing unit |

Steel to woolen roller |

|

Counting unit |

Electronic counting |

|

Machine power |

4.5KW |

|

Overall dimension |

6355*1000*1800mm |

|

Weight |

About 2000kg |

1. Transmission belt drive configuration

2. Pattern matching paper rolling device, pattern significantly

3. Electronic counting dislocation row of output

4. Folding plate and manipulator are folded and formed by a band sawing cutter

5. Other standard models can be customized

1. XY- OQ-7000A Good quality color printing napkin paper folding machine 2. XY-GU-27 Semi automatic napkin paper packing machine...

The Automatic Paper Napkin Machines are of high efficiency, reliable and easy to operate. The high speed paper folder is quite useful for those who deal in supplying big quantities,it’...

Main feature: 1. Adopt flexible printing unit, high precession ceramic anilox roll, making the water ink equally spread and print out extract and stereo pattern.(optional) 2....

the after-sales service is prompt, professional, and supportive, ensuring smooth operation and quick issue resolution.Carrier 2025-09-01

easy operation with minimal training required, flexible packaging options to suit different bag sizes, and stable performance that ensures consistent packing efficiency.Hollis 2025-09-01

The High Speed Napkin Tissue Paper Folding Machine greatly enhances production efficiency by increasing output capacity, ensuring precise folding quality, It streamlines the process, saves labor costs, and delivers consistent results, significantly improving overall manufacturing performance.Max 2025-09-01

The Automatic Transfer Napkin Tissue Paper Folding Machine and consistent output, significantly improving production speed while reducing manual labor.Zach 2025-09-01