- How to operate color printing device of napkin tissue machine→

- How to produce napkin paper?→

![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-OQ-7000A

Model:

XY-OQ-7000A

![]() Power:

10KW 380V 50HZ 3Phase

Power:

10KW 380V 50HZ 3Phase

![]() Application:

Plastic bag napkin paper production line

Application:

Plastic bag napkin paper production line

![]() Weight:

2 tons

Weight:

2 tons

![]() Output:

plastic bag napkin paper

Output:

plastic bag napkin paper

![]() Packaging Dimension:

7000*1800*2100mm

Packaging Dimension:

7000*1800*2100mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

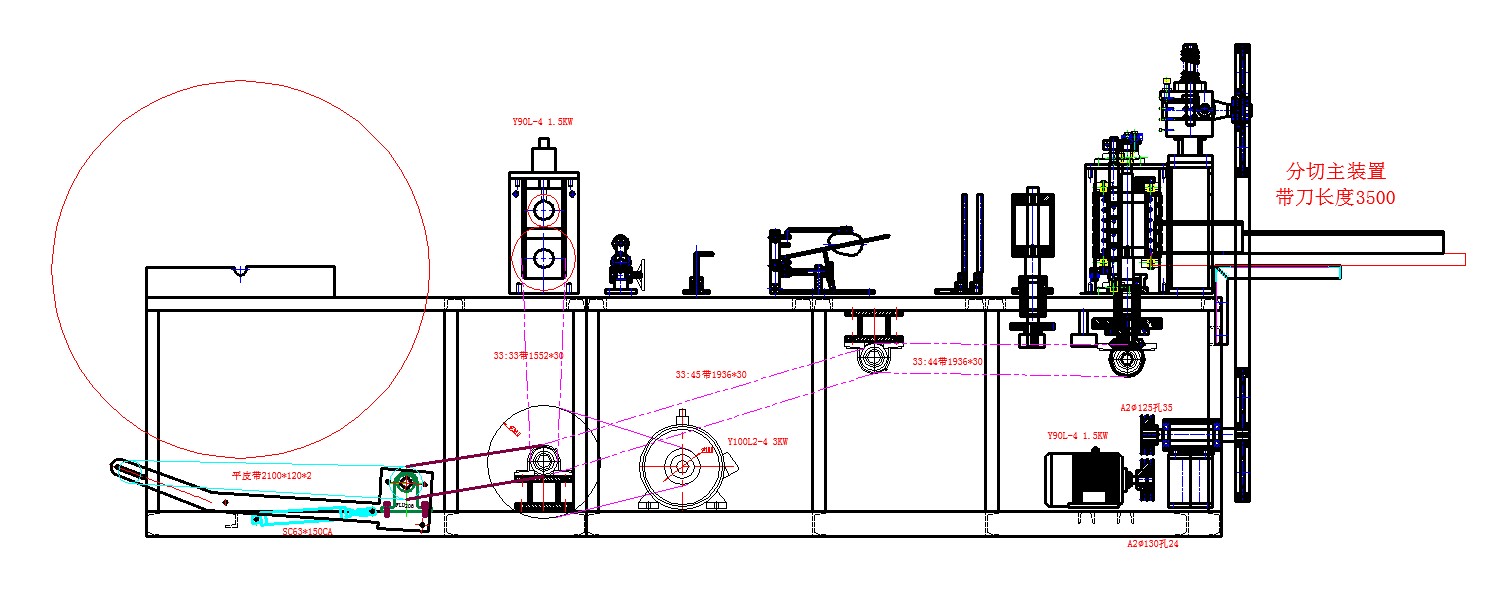

1. XY-OQ-7000A Good quality color printing napkin paper folding machine

Main feature:

1. High-Precision Printing Unit

Features a flexible printing unit with a ceramic anilox roll for even water-based ink distribution, enabling sharp and stereo patterns.

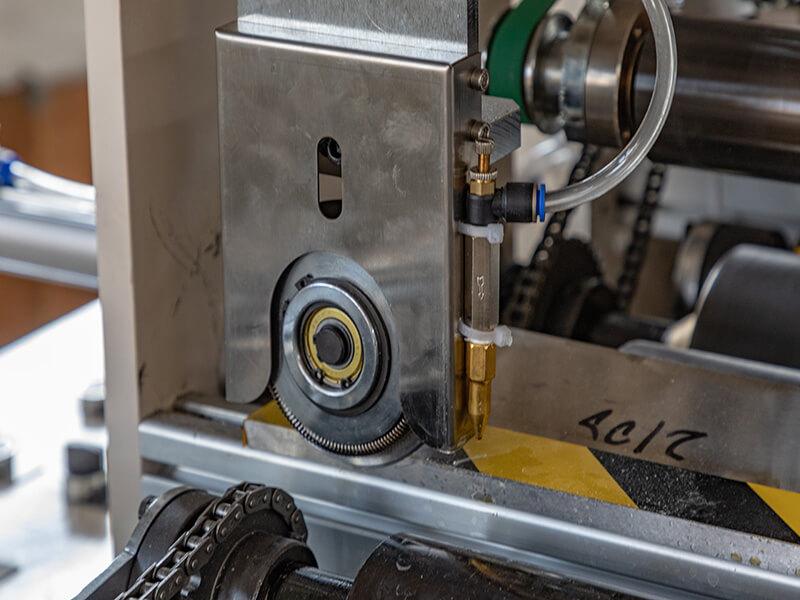

2. Material Feeding & Calendering Process

Raw material is fed via synchronous belt into the calendering unit, then proceeds to embossing. Tension control units are installed between the material input and calendering, as well as between calendering and embossing.

3. Folding Wheel Safety Mechanism

Equipped with an automatic stop protection unit for the folding wheel.

4. Auto-Correcting System

Included automatic alignment system ensures precise material positioning.

5. Intelligent Drying System

Automatic constant-temperature drying maintains optimal conditions for consistent output.

6. Comprehensive Material Protection

Broken material detection: Halts operation if material breaks.

Low-material slowdown: Reduces speed when material runs low.

Folding roller safety: Stops rollers to prevent damage during material shortage.

7. Closed-Loop Ink System

Water-based ink circulation system for efficient usage and consistent print quality.

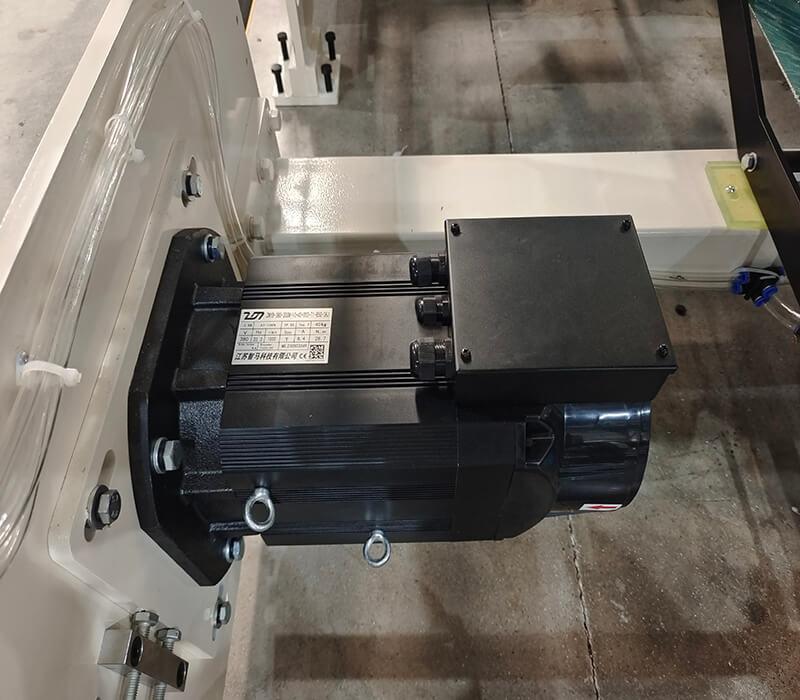

8. Fully Automatic Unreel Control

Computer-tracked speed synchronization with servo system ensures precise paper feeding into the printing unit per digital commands, delivering flawless products.

2. XY-GU-27 Semi automatic napkin paper packing machine

Characteristics:

1. Packaging versatility

Designed for single facial tissue or napkin packaging.

2. Multi-functional automation

Features automatic conveying, single-head operation, auto feeding, and auto sealing for seamless workflow.

3. Intelligent control system

Equipped with advanced PLC computer programming, dual frequency conversion control, and an LCD parameter display for effortless setup. Precise temperature regulation ensures optimal protection of heating wires and thermal-stable tapes.

4. High-efficiency operation

Delivers neat and consistent packing/sealing.

5. Quick size adjustment

Product dimensions can be easily modified via handwheel adjustments for hassle-free customization.

6. Reliable sealing technology

Double temperature-controlled sealing and cutting system guarantees flawless sealing quality and prevents film bag breakage.

7. Durable construction

Rigid frame, imported core components, and robust engineering ensure stable, high-performance operation with extended lifespan.

1. XY-OQ-7000A good quality color printing napkin paper folding machine

Technician parameter:

1.The speed: About 800-900 sheets /min

2.Unfolding size: 300*300 mm (different size with different price)

3.Folding size: 150*150mm

4.Embossing type: Full or border pattern as per requirement

5.Size of jumbo roll: width:300 mm; diameter:1200 mm

6.Diameter of jumbo roll paper core: 76.2 mm

7.Power: 4.5Kw 380V 50Hz

8.Weight: 1T

9.Space required: 4*1*1.5m

10. Function: Embossing, folding, cutting, counting.

2. XY-GU-27 Semi automatic napkin paper packing machine

Technician parameter:

1.The speed:6-10 bags /min

2.Packing size:150*150*(50-150)mm(Size must be pre-selected)

3.Packing material: Pre-made PE plastic bag

4.Power: 2.2 Kw 220V 50Hz

5.Packing size: L1800*W1650*H1400 mm

6.Packing weight: 500 kg

Start business 1/4 fold printing embossed napkin paper making machine production line including 2 machines:

1. XY-OQ-7000A good quality color printing napkin paper folding machine

2. XY-GU-27 Semi automatic napkin paper packing machine

Ideal for those new to tissue paper processing, this napkin paper production line integrates a napkin paper folding machine and a napkin paper packaging machine to streamline napkin paper production. The process is straightforward: customers only need to acquire jumbo roll and packaging bags to start creating their own napkins. The machine’s affordability significantly reduces initial costs, requiring minimal financial commitment. Its intuitive design ensures easy operation, enabling users to quickly learn and manage the production process without extensive training. The space-saving footprint of the equipment is another advantage, allowing it to be placed in tight areas without compromising efficiency. This combination of ease of use, low investment, and compact size makes it a perfect solution for beginners looking to establish themselves in the tissue paper processing industry.

1. Transmission belt drive configuration 2. Color printing device adopts flexible printing, the design can be flexibly according to you need replace, use professional color printing ani...

1.XY-OQ-7000A Automatic transfer napkin paper folding machine 2.XY-BT-298 High speed napkin paper packing machine 3. Speed: 1000 sheets/min 4. Power: 4.5KW (380V 50Hz 3Phase) 5. Raw pap...

Main feature: 1. Adopt flexible printing unit, high precession ceramic anilox roll, making the water ink equally spread and print out extract and stereo pattern.(optional) 2....

.jpg)

with clear controls and stable performance. It runs smoothly with minimal adjustments, reduces operator effort, and provides efficient, reliable production, making the overall working experience convenient and satisfying.2025-09-01

the after-sales service is prompt, professional, and supportive, ensuring smooth operation and quick issue resolution.Carrier 2025-09-01

The High Speed Napkin Tissue Paper Folding Machine greatly enhances production efficiency by increasing output capacity, ensuring precise folding quality, It streamlines the process, saves labor costs, and delivers consistent results, significantly improving overall manufacturing performance.Max 2025-09-01

"Sustainable choice verified! Setup was easy, and customer support responded quickly to queries."2026-01-26