- How to operate color printing device of napkin tissue machine→

- How to produce napkin paper?→

![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-OQ-7000A

Model:

XY-OQ-7000A

![]() Power:

4.5KW 380V 50HZ 3Phase

Power:

4.5KW 380V 50HZ 3Phase

![]() Application:

White Napkin Paper Folding Machine

Application:

White Napkin Paper Folding Machine

![]() Weight:

1.2 ton

Weight:

1.2 ton

![]() Output:

white napkin paper

Output:

white napkin paper

![]() Packaging Dimension:

5200*1000*2000mm

Packaging Dimension:

5200*1000*2000mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Main feature:

1. Adopt flexible printing unit, high precession ceramic anilox roll, making the water ink equally spread and print out extract and stereo pattern.(optional)

2. Jumbo roll through synchronous belt and come into calendaring unit, and into embossing unit. There is tension unit between jumbo roll and calendaring, jumbo roll and embossing

3. Folding wheel automatic stop machine protection unit.

4. Automatic rectify system.

5. Automatic constant temperature drying system.

6. Raw material broken protection unit. Automatic speed down unit when raw material run out. Folding roller stop protection unit.

7. Water ink circulation system.

8. Full-automatic unreel control system: track the speed of main machine by computer, transmit to servo system, the servo system convey paper to printing system accurately according to the order of computer and make perfect product.

9. Other standard models can be customized

|

Open size of finished products |

200*200~250*250mm |

300*300~330*330mm |

400*400mm |

|

Folded size of finished products |

100*100~125*125mm |

150*150~165*165mm |

200*200mm |

|

Diameter of jumbo roll paper |

1200 mm |

1200 mm |

1200 mm |

|

Diameter of jumbo roll inner core |

76.2 mm |

76.2 mm |

76.2 mm |

|

Production speed |

400~800Pcs/min(Depends on machine model) |

||

|

Color printing |

Flexographic printing 1-4 color |

||

|

Embossing unit |

Steel to woolen roller |

||

|

Counting unit |

Electronic counting |

||

|

Machine power |

4.5KW(Depends on machine model) |

||

|

Overall dimension |

5200*(700~900)*1500mm (Depends on machine model) |

||

|

Weight |

About 1400kg |

About 1500kg |

About 1600kg |

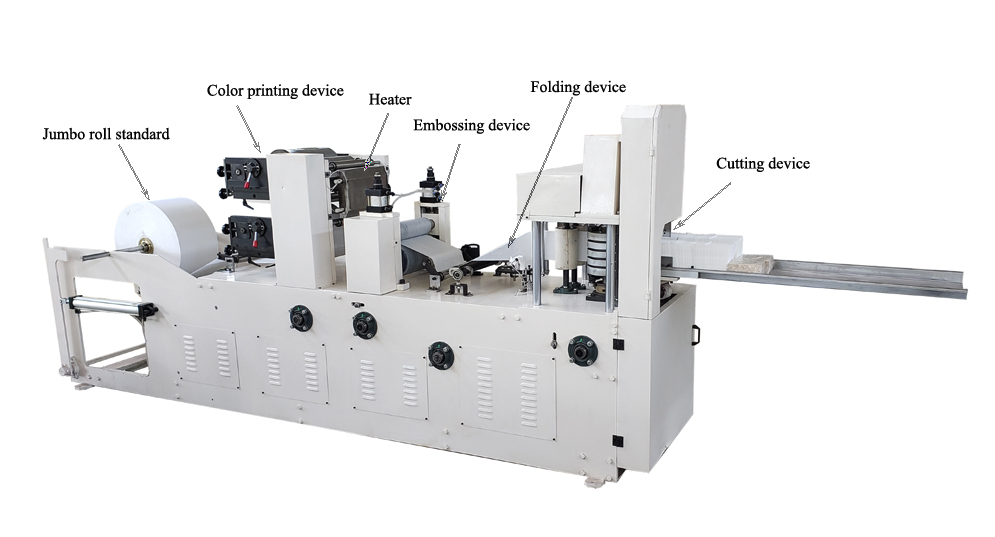

China White Napkin Tissue Paper Making Machine

This advanced tissue paper manufacturing equipment specializes in producing high-quality napkin paper from jumbo rolls. The machine integrates multiple sophisticated processes including:

1. Embossing technology that creates elegant textures (floral, geometric, or custom patterns) for enhanced aesthetics and absorbency

2. Accurate folding mechanisms for consistent napkin pleating (1/4 fold, 1/6 fold, 1/8 fold)

3. Automated counting systems with optical sensors for precise quantity control

4. High-speed cutting units that transform continuous rolls into either square or rectangle napkins with clean edges

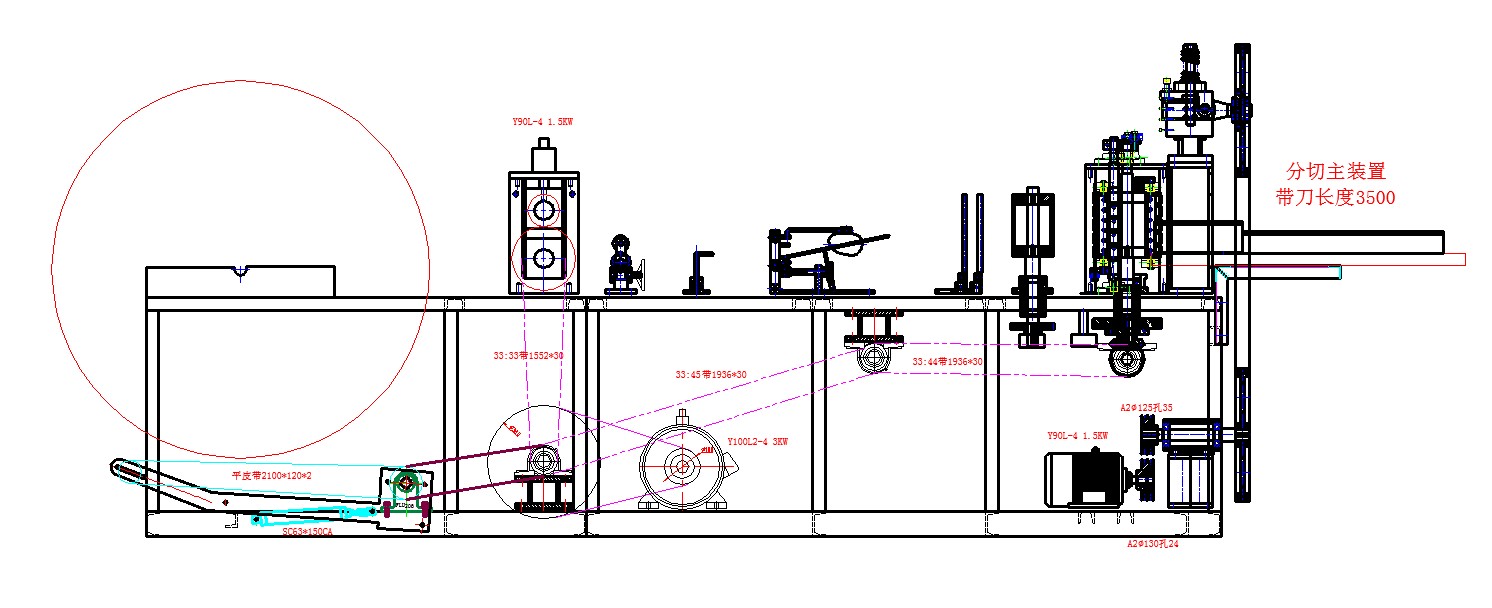

1. Transmission belt drive configuration 2. Color printing device adopts flexible printing, the design can be flexibly according to you need replace, use professional color printing ani...

Main feature: 1. Adopt flexible printing unit, high precession ceramic anilox roll, making the water ink equally spread and print out extract and stereo pattern.(optional) 2....

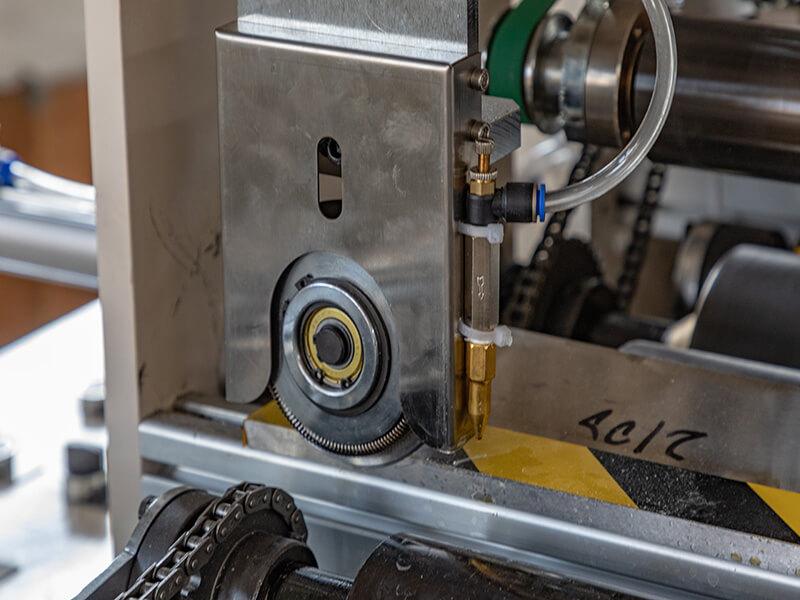

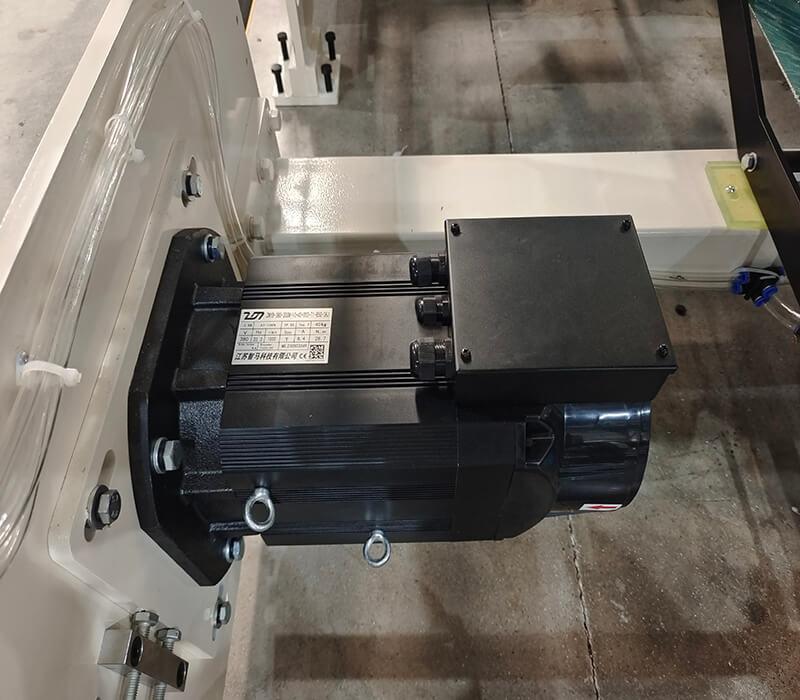

1. PLC controlling system 2. Servo drives 3. Frequency converter 4. Yudian temperature module 5. up-to-dated touch screen integrated to control and driving center,with faster calculati...

The Automatic Transfer Napkin Tissue Paper Folding Machine and consistent output, significantly improving production speed while reducing manual labor.Zach 2025-09-01

.jpg)

with clear controls and stable performance. It runs smoothly with minimal adjustments, reduces operator effort, and provides efficient, reliable production, making the overall working experience convenient and satisfying.2025-09-01

The High Speed Napkin Tissue Paper Folding Machine greatly enhances production efficiency by increasing output capacity, ensuring precise folding quality, It streamlines the process, saves labor costs, and delivers consistent results, significantly improving overall manufacturing performance.Max 2025-09-01

easy operation with minimal training required, flexible packaging options to suit different bag sizes, and stable performance that ensures consistent packing efficiency.Hollis 2025-09-01