- How to operate color printing device of napkin tissue machine→

- How to produce napkin paper?→

![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-BT-298

Model:

XY-BT-298

![]() Power:

7.26KW 380V 50HZ 3Phase

Power:

7.26KW 380V 50HZ 3Phase

![]() Application:

Napkin paper&facial tissue packing machine

Application:

Napkin paper&facial tissue packing machine

![]() Weight:

3000kg

Weight:

3000kg

![]() Output:

napkin paper and facial tissue

Output:

napkin paper and facial tissue

![]() Packaging Dimension:

100-230mm*90-150mm*50-120mm

Packaging Dimension:

100-230mm*90-150mm*50-120mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

Application: This machine is mainly used for Facial Tissue or Napkin Paper Three Dimensional Packing.

Main performance and structure features:

1. The machine features a simple structure, with both the power system and packaging system featuring a brand-new open design for easy adjustment and maintenance. The machine's compact size and small footprint facilitate layout, operation, and maintenance. Its robust construction minimizes vibration during operation and ensures stable packaging results.

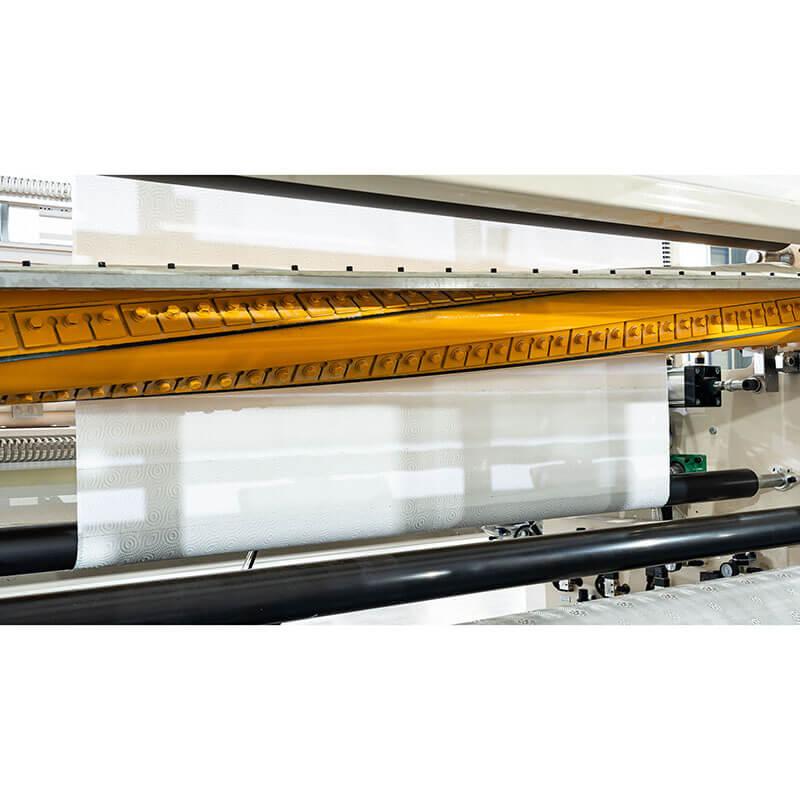

2. The film slitting and dotted line cutters utilize spring-loaded rotating blades powered by a servo motor. They deactivate when no material is present, extending the life of the cutters.

3. The rear-flipping package pressing mechanism simplifies adjustment and ensures stable, aesthetically pleasing packaging results.

4. The box-type combined structure ensures high vibration and stability.

5. The user-friendly human-machine interface automatically calculates the initial position after entering packaging parameters, and the settings can be saved, facilitating format changes and reducing changeover time. 6. The three-dimensional packaging system, which combines wrapping, folding, and sealing, offers a compact and aesthetically pleasing structure, with excellent end-sealing and side-iron effects.

7. The anti-empty packaging function, with increased material handling unit levels and auxiliary photoelectric tracking before feeding, prevents continuous and multiple packs, as well as oversized or undersized paper, improving product packaging quality. The feed conveyor mechanism prevents unqualified tissues from passing through and prevents film from being applied to empty packs, maximizing packaging material savings.

8. An electronic handwheel replaces a mechanical one, providing convenient and precise control.

9. An alarm function for over-length and under-short feed paper prevents mechanical damage caused by paper over-length and under-short errors, preventing unqualified products from being packaged and wasting film due to uneven paper lengths. This also reduces product scrap rates.

10. Optional ribbon printer (standard).

11. Equipped with an automatic film tension adjustment device.

12. Automatic film application stop function (no paper, no film applied);

13. Optional custom-shaped tearing device (optional).

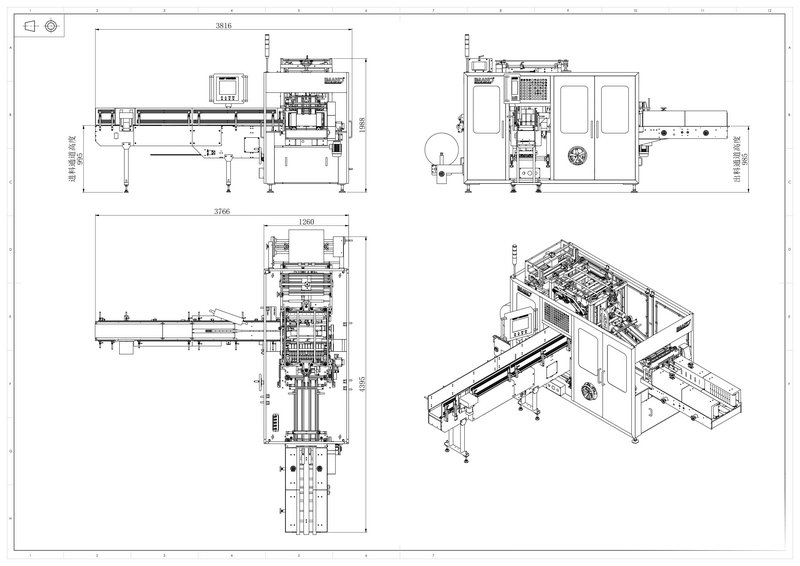

|

Model |

XY-BT-298 |

|

Outline Dimension (mm) |

3560*5885*1925 |

|

Speed (bags / min) |

50-70 |

|

Packing size (mm)After folding size |

100-230*90-150*40-100 |

|

Machine's Weight (KG) |

3000 |

|

Motor Consumption (KW) |

3.66 |

|

Heating Consumption (KW) |

3.6 |

|

Power |

380V 50Hz |

|

Power Consumption (KW) |

7.26 |

|

Packing film |

CPP,PE,OPP/CPP,PT/PE and other film sealed on both sides |

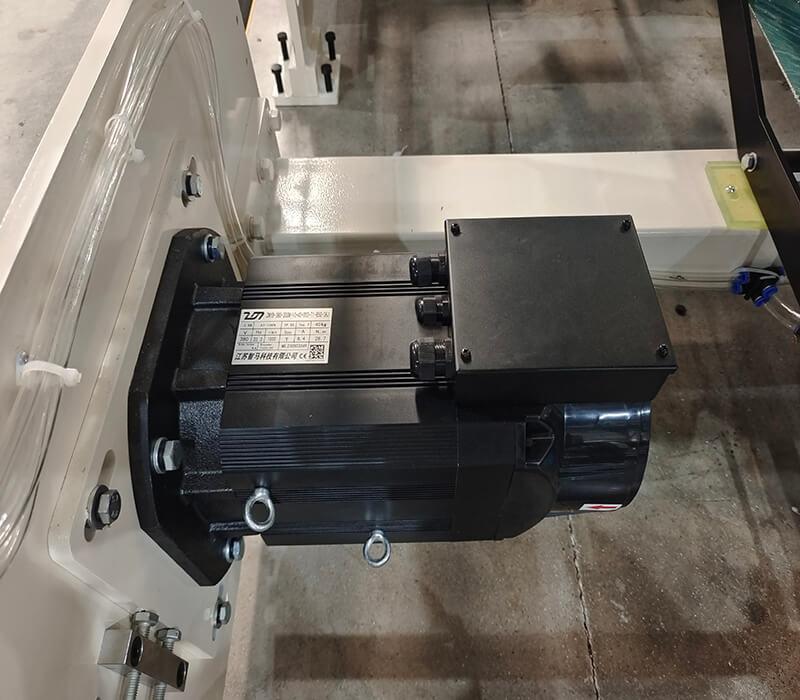

This machine adopts:

1. PLC controlling system

2. Servo drives

3. Frequency converter

4. Yudian temperature module

5. up-to-dated touch screen integrated to control and driving center,with faster calculating speed,to greatly improve the control precision and reliability.

The new kind of material sorting structure solves multiple packs and empty packs problem so as to make sure the productively is increase greatly,which can reflect more for automation and intelligent.

The Automatic Paper Napkin Machines are of high efficiency, reliable and easy to operate. The high speed paper folder is quite useful for those who deal in supplying big quantities,it’...

1. PLC controlling system 2. Servo drives 3. Frequency converter 4. Yudian temperature module 5. up-to-dated touch screen integrated to control and driving center,with faster calculati...

1.XY-OQ-7000A Automatic transfer napkin paper folding machine 2.XY-BT-298 High speed napkin paper packing machine 3. Speed: 1000 sheets/min 4. Power: 4.5KW (380V 50Hz 3Phase) 5. Raw pap...

.jpg)

with clear controls and stable performance. It runs smoothly with minimal adjustments, reduces operator effort, and provides efficient, reliable production, making the overall working experience convenient and satisfying.2025-09-01

easy operation with minimal training required, flexible packaging options to suit different bag sizes, and stable performance that ensures consistent packing efficiency.Hollis 2025-09-01

The High Speed Napkin Tissue Paper Folding Machine greatly enhances production efficiency by increasing output capacity, ensuring precise folding quality, It streamlines the process, saves labor costs, and delivers consistent results, significantly improving overall manufacturing performance.Max 2025-09-01

The Automatic Transfer Napkin Tissue Paper Folding Machine and consistent output, significantly improving production speed while reducing manual labor.Zach 2025-09-01