![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-NGU-21C

Model:

XY-NGU-21C

![]() Power:

15.5KW 380V 50HZ 3Phase

Power:

15.5KW 380V 50HZ 3Phase

![]() Application:

Pocket tissue paper production line

Application:

Pocket tissue paper production line

![]() Weight:

4 tons

Weight:

4 tons

![]() Output:

Pocket tissue paper

Output:

Pocket tissue paper

![]() Packaging Dimension:

3490*9600*1800mm

Packaging Dimension:

3490*9600*1800mm

![]() Machine Size:

Machine Size:

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

![]() Certification:

CE, ISO

Certification:

CE, ISO

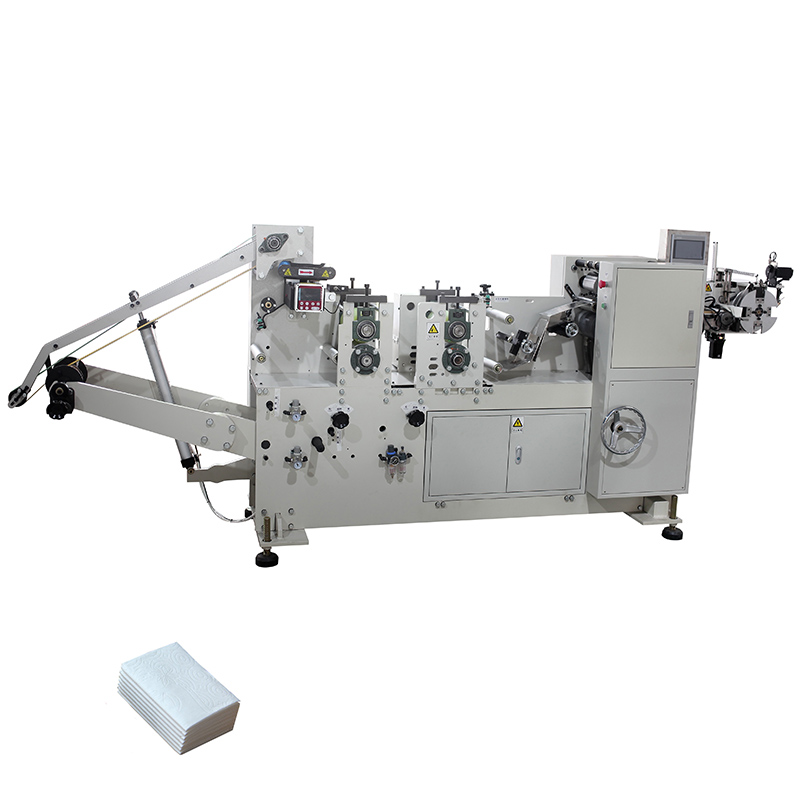

1. Pocket tissue (handkerchief tissue) folding machine with separator

Speed of the separator: 60 bags/min

Programming control: PLC

Parameter setting: Touch screen

Speed control: Frequency converter

Raw material:13-25gm 1-3plies

Width of jumbo roll:210mm

Outer Dia. of jumbo roll:1100mm

Inner Dia. of jumbo roll core:76.2mm

Braking:Pneumatic

Embossing unit:single embossing (steel to rubber, stamp designed by user)

Vacuum pump: 5.5Kw, 380V, 50Hz

Production speed:600PCS/min (controlled by frequency converter)

Finished products unfold size: 210*210mm

Finished products folded size: 102*52mm and 72*52mm

Main transmission: chain and chain wheel transmission

Power: 0.75kw, 380v, 50Hz

Pressure of pneumatic system:6kg/cm2(user supplied)

Counter: electronic counter

Overall size: 3851×650×1380mm(L×W×H)

Over weight: about 1T

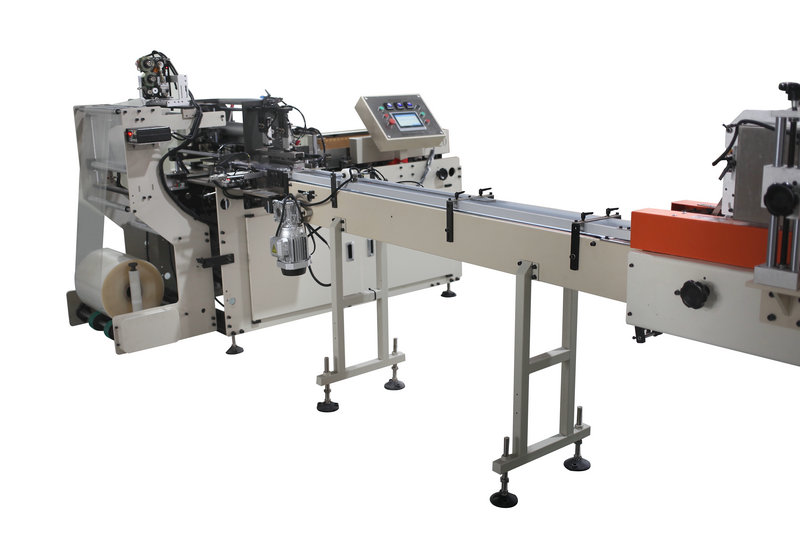

2. Automatic pocket tissue (handkerchief tissue) packing machine

Size of finished product: standard size:L=102mm, W=52mm, H=22-26mm

Mini size:L=72mm, W=52mm, H=22-26mm

Machine speed: 105bags/min

Stable speed: 90bags/min

Heating power: 3.5Kw, 220V, 50Hz

Drive power: 1.5Kw, 380V, 50Hz

Packing material: double-sided heat sealing membrane such as CPP, PE, CPP

Programming control: PLC (SIEMENS)

Frequency converter: MITSUBISHI

Air pressure: 0.6Mpa (user supplied)

Parameter setting: Touch screen (WEINVIEW)

Step Motor: 0.38Kw, 380V, 50Hz (KINCO)

Machine size: 2840*2650*1720mm (L*W*H)

Screws: All are hexagon socket

Machine weight: 1.5T

3. Automatic pocket tissue (handkerchief tissue) wrapping machine (single channel)

Size of finished product: 5*2(standard size:260*102*44/52mm, mini size:260*72*44/52mm)Machine speed: 8-12bags/min

Heating power: 1.78Kw, 380V, 50Hz

Drive power: 1.5Kw, 380V, 50Hz

Packing material: double-sided heat sealing membrane such as CPP, PE, etc.

Programming control: PLC (SIEMENS)

Frequency converter: MITSUBISHI

Air pressure: 0.6Mpa (user supplied)

Parameter setting: Touch screen (WEINVIEW)

Step Motor: 0.38Kw, 380V, 50Hz (WOTO)

Machine size: 2500*2350*1550mm (L*W*H)

Machine weight: 1.4T

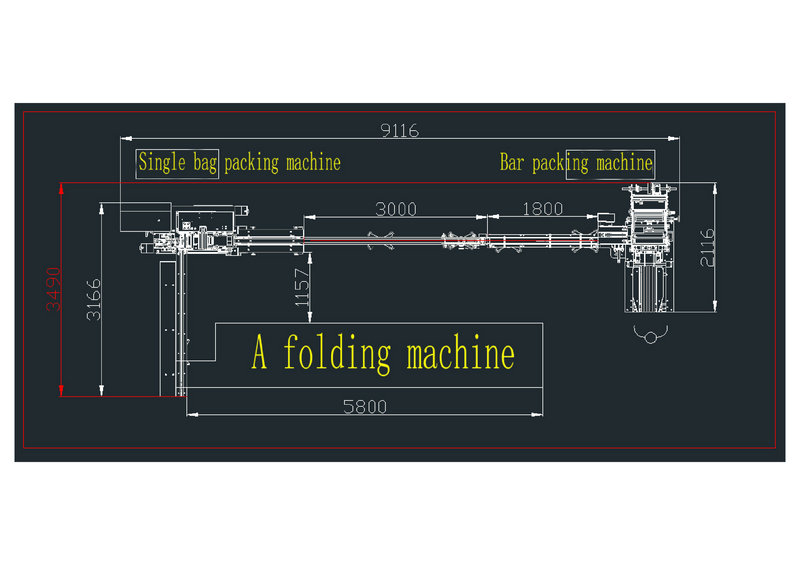

|

Overall dimension(mm) |

9116L*3490W*1360H |

|

Width of jumbo roll paper |

180-210mm |

|

Diameter of jumbo roll paper |

Max. 1500mm |

|

Diameter of jumbo roll paper inner core |

76mm |

|

Open size of finished products |

200/205/210mm |

|

Folded size of finished products |

(65-115)*(50-53)mm |

|

Embossing Unit |

Steel to Rubber, Steel to Steel(Optional) |

|

Separating piece |

8/9/10 |

|

Speed |

70-75 bags/min |

|

Weight |

3000kg |

|

Power |

2.2 KW |

|

Blower Power |

5.5 KW |

Automatic handkerchief paper production line is consists of three parts:

1. Handkerchief Folding Machine, Separating Unit

2. Single Bag Packing Machine

3. Multiple Bags Packing Machine.

Raw materialfrom jumbo roll first through color printing unit(optional), Then embossing andfolding into handkerchief paper. And then separated into different sets by separating unit, then go to the single bag packing and multiple bags packing.

This line realizes the whole production process is automatic.It greatly improve the efficiency and reduce labor cost and easy to operate.It adopts failures tracing and alarm system, failures will be found and settle immediately, which save the lost in a maximum way. Handkerchief folding size, tissue number of each bag and multiple packing bag number all can be made according to clients’ requirement.

Embossing miniature handkerchief paper machine adopts vacuum adsorption, embossing, cutting, automatic folding, finished product is easy to carry. 一、Main functional characteristics...

1. Handkerchief Folding Machine, Separating Unit 2. Single Bag Packing Machine 3. Multiple Bags Packing Machine....

It ensures precise cutting and folding, consistent output, and high durability. The reliable design reduces maintenance needs, providing a satisfying and efficient production experience.Thompson 2025-09-01

The full automatic pocket tissue paper making machine production line delivers high efficiency, stable performance, and reduced labor costs, ensuring consistent output and reliable productivity.Aron 2025-09-02

we’ve seen a 20% increase in efficiency since switching to this full automatic handkerchief paper production line2025-11-04

The pocket tissue paper production line automated feeding system reduces material waste by 15%, and the maintenance team provided excellent training.2025-11-04