Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2025-09-08

A tissue paper making machine is a large-scale industrial unit that transforms raw materials such as wood pulp, recycled paper, or mixed fiber into finished tissue rolls. Unlike traditional paper machines, which are designed for printing or packaging paper, tissue paper machines are engineered to produce lightweight, soft, and high-absorbency sheets.

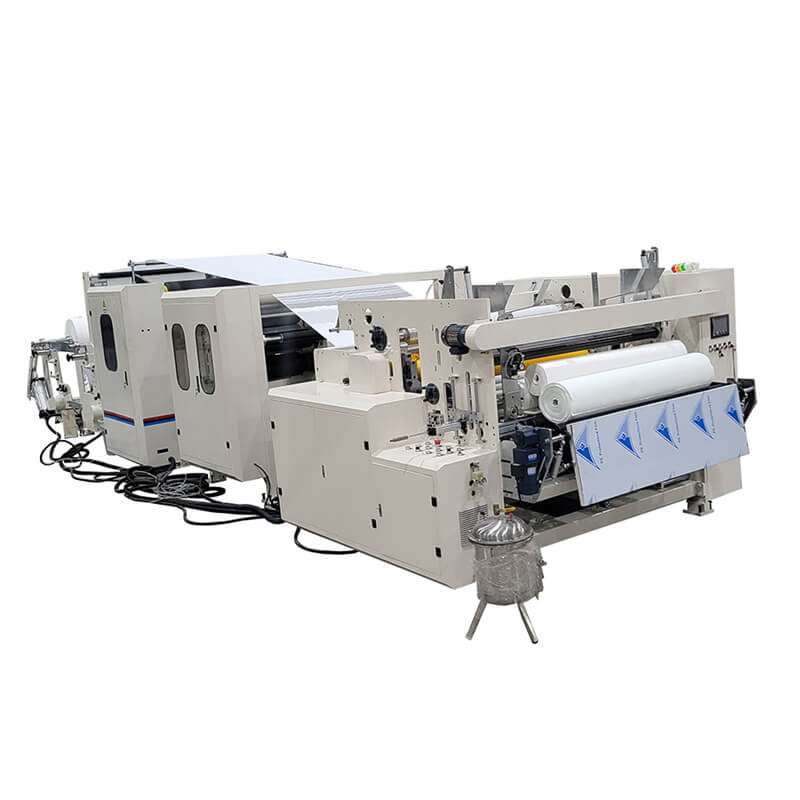

The machine typically consists of several sections: the pulp preparation system, where raw fibers are processed; the forming section, where a thin web of tissue is created; the pressing and drying section, which removes moisture; and the rewinding and converting system, which cuts and rolls the tissue into usable sizes. The efficiency and quality of each stage directly influence the softness, thickness, and strength of the final tissue product.

Tissue paper machines are classified into several types depending on the scale of production, product type, and technological sophistication. The two primary categories are manual/semi-automatic machines and fully automatic machines.

Manual and semi-automatic machines are more affordable and suitable for small-scale businesses. They require more human intervention in feeding raw materials and handling the finished rolls.

Fully automatic tissue paper machines, on the other hand, can perform every step—from pulping and forming to embossing, perforation, and packaging—without human intervention. These machines are equipped with computerized control systems, ensuring consistent quality and higher productivity.

Additionally, some machines are designed for specific tissue products, such as napkins, facial tissues, or jumbo toilet paper rolls. Manufacturers often customize machines to meet the unique needs of businesses, from large-scale paper mills to small entrepreneurial setups.

The process begins with pulp preparation, where virgin wood pulp or recycled paper is mixed with water and chemicals to achieve the desired fiber quality. Next, the diluted pulp is spread onto a moving wire mesh in the forming section, creating a continuous web of wet paper.

This sheet then passes through the pressing section, where rollers squeeze out excess water. The partially dried sheet moves into the drying section, usually involving large heated cylinders (commonly called Yankee dryers), where steam or gas heat evaporates the remaining moisture. To achieve softness, a process known as creping is applied, where a doctor blade scrapes the tissue from the dryer surface, giving it a crinkled and soft texture.

Finally, the tissue web is rewound into large parent rolls, which are later converted into finished products like napkins, facial tissues, or toilet rolls. Each step requires precision, as even minor errors can result in tears, uneven thickness, or poor absorbency.

For tissue manufacturers, efficiency is critical in balancing cost and quality. Modern tissue paper machines are capable of producing up to 2,000 meters of tissue per minute, depending on machine size and technology. High-speed machines reduce operational costs by minimizing downtime and maximizing production capacity.

Automation plays a central role in improving efficiency. Advanced control systems allow operators to monitor moisture levels, fiber distribution, and creping quality in real-time. This minimizes waste, reduces labor requirements, and ensures uniformity in product quality. Energy-saving technologies, such as optimized drying systems and water recycling units, further enhance operational efficiency while lowering production costs.

As the demand for tissue products grows, so does the environmental concern surrounding the use of virgin pulp and the energy-intensive drying process. Tissue paper making machines are being redesigned with sustainability in mind.

Many manufacturers now use recycled paper as a major raw material, reducing the pressure on forests. Water consumption has also been significantly reduced through closed-loop water recycling systems. Furthermore, energy-efficient drying technologies such as gas-fired hoods and heat recovery systems help minimize carbon emissions.

Some innovative machines incorporate biodegradable chemicals and eco-friendly bleaching methods to reduce environmental pollution. With growing consumer preference for eco-conscious products, sustainable tissue production is not just an ethical choice but also a competitive advantage for manufacturers.

The future of tissue paper making machines is strongly influenced by automation, digitalization, and sustainability. Smart sensors and Internet of Things (IoT) technologies are being integrated into machines to allow predictive maintenance, reducing breakdowns and ensuring uninterrupted production.

Artificial intelligence is also being explored for process optimization, such as adjusting pulp ratios, controlling moisture content, and predicting consumer demand trends. At the same time, compact and energy-efficient machines are being developed to cater to small-scale businesses and startups in emerging markets.

In terms of sustainability, research is focused on alternative raw materials such as agricultural residues and bamboo fibers, which are renewable and environmentally friendly. The combination of eco-friendly materials and advanced automation will define the next generation of tissue paper machines.

Tissue paper making machines are the backbone of the global tissue industry, enabling the production of essential products that touch everyday life. From their basic working principles to modern high-speed, fully automated systems, these machines have evolved significantly to meet rising global demand. Efficiency, product quality, and sustainability remain the key driving forces behind technological innovations.

As consumer awareness of hygiene and environmental issues increases, the tissue paper industry is set to grow further, with machines adapting to produce eco-friendly, affordable, and high-quality products. In the future, smart automation and sustainable raw materials will shape not only how tissue paper is produced but also how the industry contributes to a cleaner and greener world.