Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2026-01-22

In the bustling world of paper manufacturing, selecting the appropriate toilet paper machine is a pivotal decision that can significantly impact your factory's productivity, product quality, and overall profitability. With a myriad of options available in the market, each boasting unique features and capabilities, making an informed choice requires careful consideration of several key factors. This blog post aims to guide you through the process of choosing the right toilet paper machine for your factory.

Before diving into the technical specifications of toilet paper machines, it's crucial to have a clear understanding of your factory's production requirements. Consider the following:

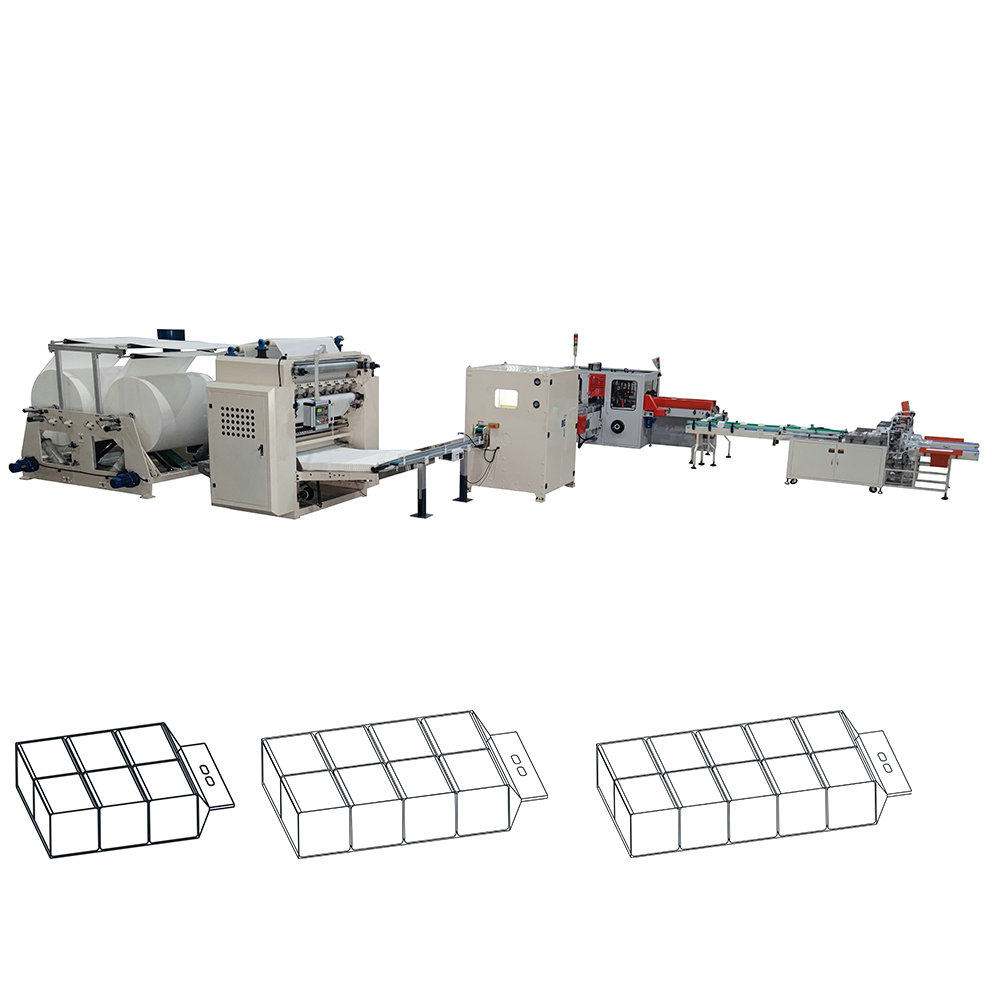

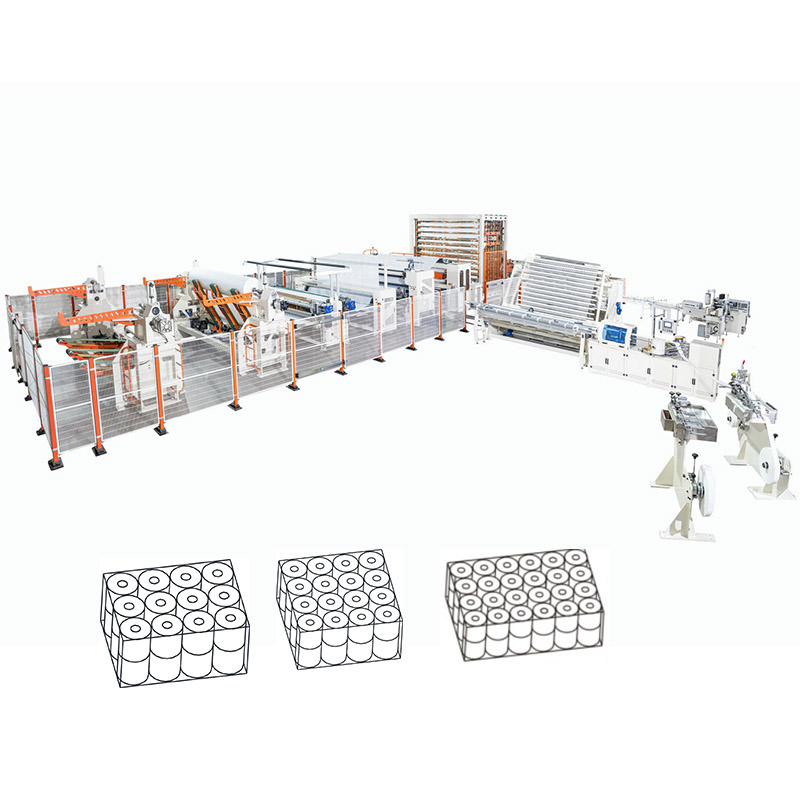

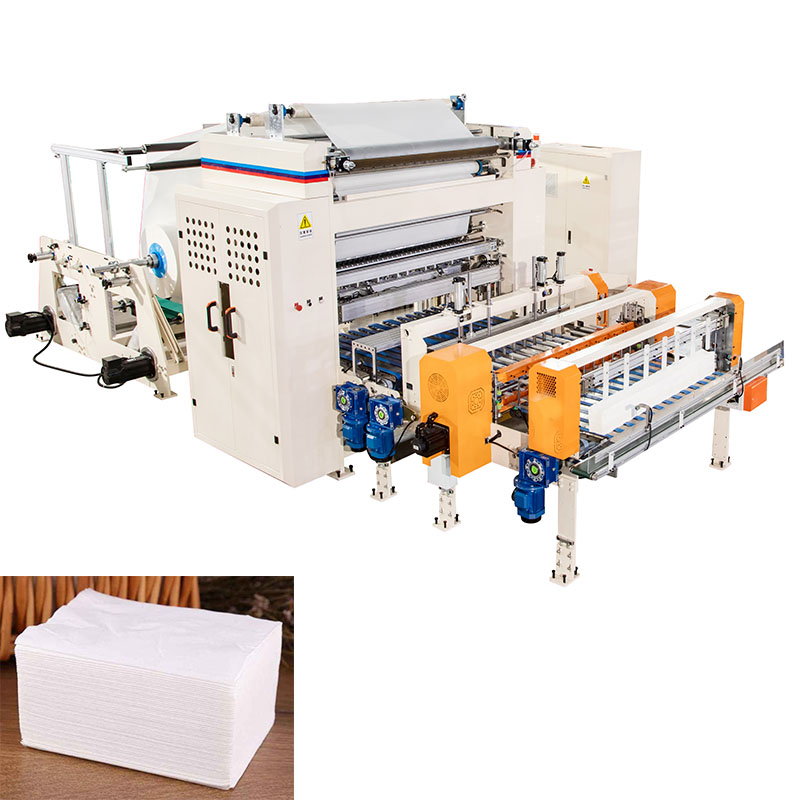

Toilet paper machines come in various types, each designed for specific production scales and purposes. The main types include:

Consider the technology embedded in these machines, such as PLC (Programmable Logic Controller) systems for precise control, servo motors for accurate positioning, and touch screen interfaces for user-friendly operation.

The quality and durability of the toilet paper machine are paramount to ensuring long-term reliability and minimal downtime. Look for machines constructed from high-quality materials, such as stainless steel, that can withstand the rigors of continuous operation. Pay attention to the machine's design, ensuring it is robust and well-engineered to handle the stresses of production.

Additionally, consider the machine's maintenance requirements. Opt for machines that are easy to clean, lubricate, and repair. Regular maintenance is essential to prolonging the machine's lifespan and maintaining optimal performance.

In today's environmentally conscious world, energy efficiency and sustainability are crucial considerations. Choose a toilet paper machine that is designed to minimize energy consumption and reduce waste. Look for features like energy-efficient motors, automatic shut-off systems, and waste recycling capabilities.

Moreover, consider the machine's impact on the environment during its lifecycle. Opt for machines that use eco-friendly materials and manufacturing processes, and that can be easily recycled or disposed of at the end of their useful life.

The availability of reliable after-sales support and service is critical to ensuring the smooth operation of your toilet paper machine. Choose a manufacturer or supplier that offers comprehensive after-sales services, including installation, training, technical support, and spare parts availability.

Consider the manufacturer's reputation in the industry and their track record of providing excellent customer service. Read reviews and testimonials from other customers to gauge their satisfaction with the manufacturer's support and service.

While cost should not be the sole determining factor, it is undoubtedly an important consideration when choosing a toilet paper machine. Compare prices from different manufacturers and suppliers, taking into account the machine's features, quality, and after-sales support.

Remember that the cheapest option may not always be the best value for money. Consider the long-term costs associated with the machine, such as maintenance, energy consumption, and potential downtime, to determine its overall cost-effectiveness.

Choosing the right toilet paper machine for your factory is a complex decision that requires careful consideration of several key factors. By understanding your production needs, evaluating machine types and technologies, assessing quality and durability, considering energy efficiency and environmental impact, evaluating after-sales support and service, and comparing prices and value for money, you can make an informed choice that will benefit your factory for years to come.

Investing in the right toilet paper machine is not just about purchasing a piece of equipment; it's about investing in the future success and profitability of your factory. So, take your time, do your research, and choose wisely.