Toilet Paper Machine Working Process Explained by Xinyun

Introduction

In our daily lives, toilet paper is an indispensable commodity. It's used in various settings, from homes to public restrooms, providing convenience and hygiene. But have you ever wondered how this soft and essential product is made? The Xinyun toilet paper machine, a marvel of modern manufacturing technology, orchestrates a complex yet fascinating process to transform raw materials into the toilet paper we know and use every day. Let's delve into the detailed working process of this remarkable machine.

1. Raw Material Preparation

The first step in the production of toilet paper is preparing the raw materials. The main ingredients are different types of pulp, such as wood pulp, bamboo pulp, and recycled paper pulp. These pulps are usually stored in large bales or as loose fibers.

-

Pulp Breaking: The bales of pulp are fed into a pulper. This machine uses high - speed rotation and the addition of water to break the pulp into a homogeneous suspension. The amount of water added is carefully controlled to achieve the right pulp consistency. Too much water will make the pulp too thin, while too little will result in a lumpy and uneven mixture.

-

Fiber Separation: After pulping, the mixture may contain some large impurities or un - separated fiber bundles. Special screens and separators are used to remove these unwanted elements, ensuring that only fine and well - dispersed fibers move forward in the production process.

2. Pulp Refining

Refining is a crucial step that improves the quality of the pulp fibers. The refined pulp will produce toilet paper with better strength, softness, and absorbency.

-

Mechanical Refining: The pulp suspension is passed through refiners, which are equipped with rotating discs or rollers. These components exert pressure on the fibers, causing them to fibrillate. Fibrillation increases the surface area of the fibers, allowing them to bond more effectively with each other during the paper - making process. This results in a stronger and more durable paper product.

-

Chemical Addition (Optional): In some cases, chemicals may be added during refining to further enhance the properties of the pulp. For example, wet - strength agents can be added to make the toilet paper more resistant to water, especially useful for wet - wipe applications. Softening agents can also be incorporated to improve the tactile feel of the final product.

3. Paper Formation

Once the pulp is properly refined, it is ready to be formed into paper. This is the core part of the toilet paper - making process, where the pulp suspension is transformed into a continuous sheet of paper.

-

Headbox Distribution: The refined pulp suspension is pumped into a headbox. The headbox evenly distributes the pulp onto a moving wire mesh. The wire mesh acts as a support structure during the initial stages of paper formation.

-

Drainage and Fiber Bonding: As the wire mesh moves forward, water from the pulp suspension drains through the mesh under the influence of gravity and vacuum suction. At the same time, the fibers in the pulp start to bond together through hydrogen bonding and mechanical entanglement. This forms a wet paper web with a certain degree of strength.

4. Pressing

The wet paper web still contains a significant amount of water, which needs to be removed to increase the paper's density and strength.

-

Press Rolls: The wet paper web passes through a series of press rolls. These rolls apply pressure to the paper, squeezing out the excess water. The pressure is carefully adjusted to ensure that the paper is dewatered effectively without causing damage to the fiber structure. Multiple press rolls are often used in a sequential manner to achieve the desired moisture content.

5. Drying

After pressing, the paper web is still relatively wet and needs to be dried to reach the appropriate moisture level for toilet paper.

-

Drying Cylinders: The paper web is transferred to a set of heated drying cylinders. These cylinders are usually steam - heated and rotate continuously. As the paper web comes into contact with the hot surface of the cylinders, the remaining water evaporates, gradually reducing the moisture content of the paper. The temperature and speed of the drying process are precisely controlled to prevent the paper from becoming too brittle or too soft.

-

Air Drying (Optional): In some advanced toilet paper machines, an additional air - drying stage may be included. This involves blowing hot air over the paper web to further enhance the drying efficiency and ensure uniform moisture distribution throughout the paper.

6. Calendaring

Calendaring is the process of smoothing and finishing the surface of the dried paper.

-

Calender Rolls: The paper passes through a set of calender rolls, which are highly polished metal rolls. The rolls apply pressure to the paper surface, flattening any rough spots and creating a uniform thickness. This not only improves the appearance of the toilet paper but also enhances its softness and smoothness, making it more comfortable to use.

7. Rewinding and Cutting

The continuous sheet of paper that has undergone all the previous processes is now ready to be converted into the familiar toilet paper rolls.

-

Rewinding: The paper is wound onto large parent rolls using a rewinding machine. The rewinding process allows for the adjustment of the roll diameter and tension according to the product specifications.

-

Cutting: The parent rolls are then transferred to a cutting machine, which cuts the paper into the standard lengths required for individual toilet paper rolls. The cutting is done with high precision to ensure consistent roll sizes.

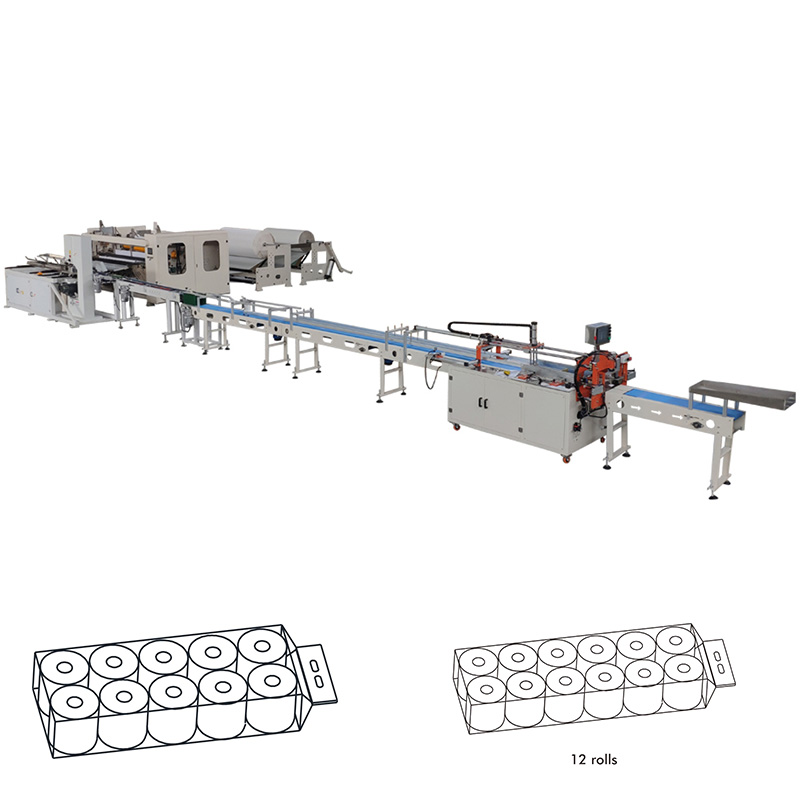

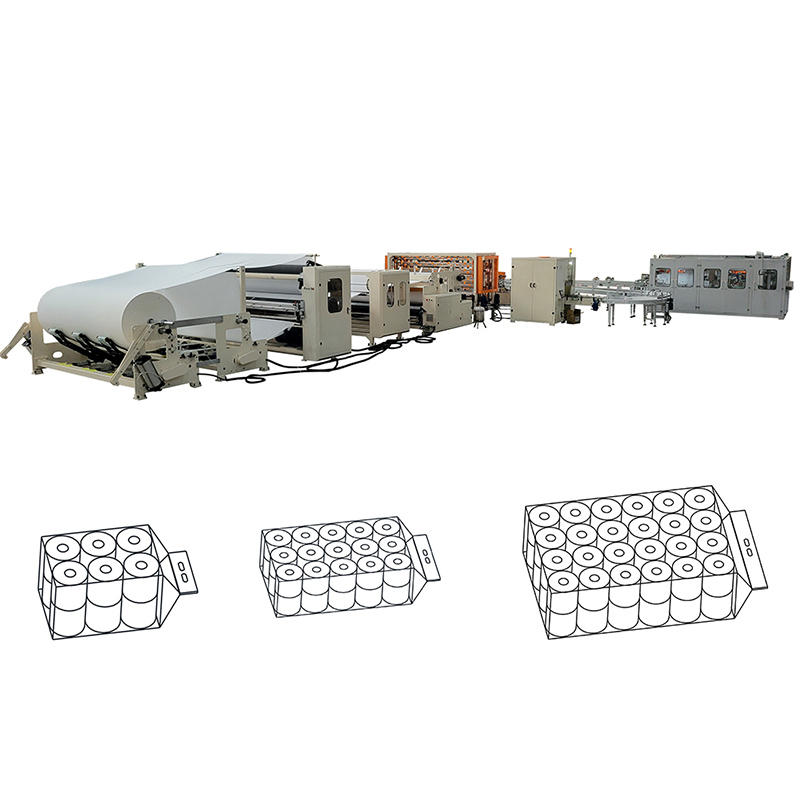

8. Packaging

The final step in the production process is packaging the cut toilet paper rolls.

-

Packing Machines: The rolls are placed into plastic bags or cardboard boxes using automated packing machines. The packaging is designed to protect the toilet paper during transportation and storage, while also providing attractive presentation for consumers. Information such as the brand name, product features, and usage instructions are printed on the packaging.

Conclusion

The working process of the Xinyun toilet paper machine is a well - orchestrated sequence of steps that combines mechanical, chemical, and thermal processes. From the initial preparation of raw materials to the final packaging of the finished product, each stage plays a vital role in ensuring the production of high - quality, soft, and absorbent toilet paper. This sophisticated machine not only meets our daily hygiene needs but also represents the pinnacle of modern manufacturing technology in the paper - making industry.