Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2025-08-22

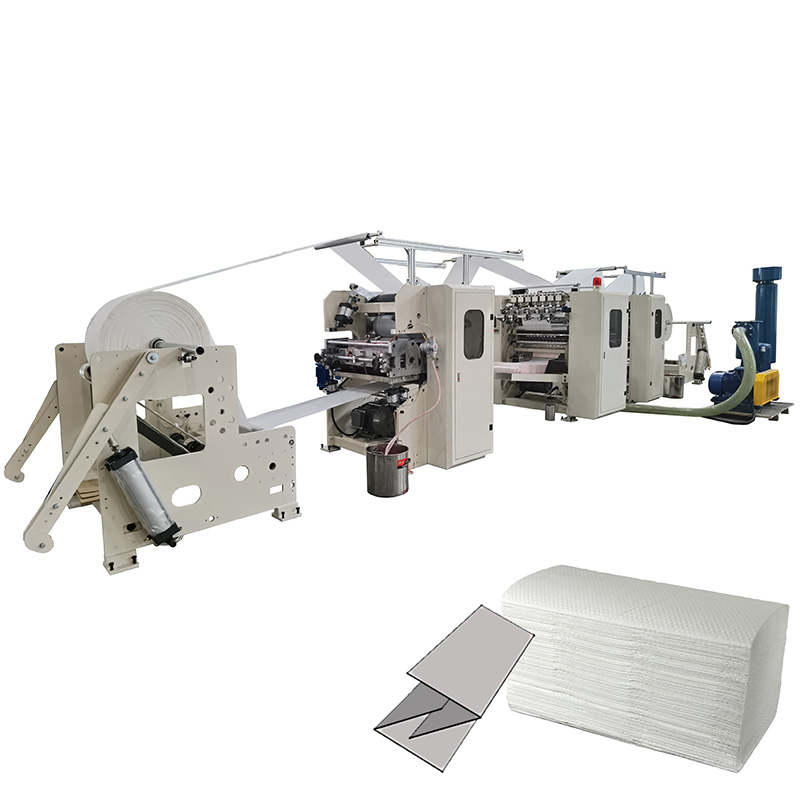

The facial tissue production line is a complete set of machinery designed to convert raw paper jumbo rolls into consumer-ready facial tissues. With growing demand for hygiene products worldwide, manufacturers seek efficient and automated solutions that guarantee speed, quality, and consistency. A modern production line integrates unwinding, embossing, folding, cutting, counting, and packing, offering seamless operation from raw material to finished product. Beyond functionality, such lines also deliver a host of advantages, from reducing labor costs to improving product hygiene and market competitiveness. This article highlights the core functions and advantages of facial tissue production lines, with a special focus on how related equipment such as napkin tissue packing machines reflect similar innovations.

Automation is the cornerstone of both napkin tissue packing machines and facial tissue production lines. Just as the napkin tissue packing machine reduces manual intervention in folding and packaging, the facial tissue line automates every step of production—from unwinding large rolls to precise sheet cutting and folding. This automation ensures consistent product size, softness, and quality while eliminating human error.

For manufacturers, automation translates into higher throughput and reduced labor dependence. Operators primarily supervise rather than manually handle products, improving workplace efficiency. The smooth transition of raw material to finished tissues mirrors the streamlined functions observed in advanced packing machines, proving that automation is the foundation of productivity in the tissue industry.

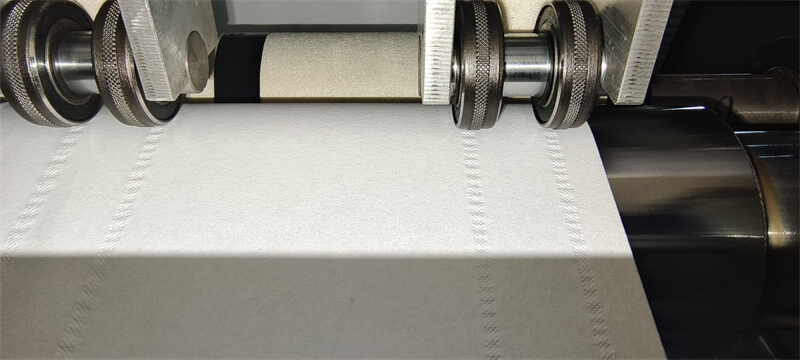

Folding is one of the most critical functions in tissue manufacturing. While a napkin tissue packing machine focuses on neat folding for napkins, the facial tissue production line employs specialized folding units that achieve uniform interfolding. This design allows tissues to be dispensed one at a time, enhancing user convenience and reducing waste.

Precision folding also improves product presentation, ensuring that each box of tissues looks appealing and professional. For businesses, this consistency builds consumer trust. By comparing with napkin packing systems, it becomes clear that folding precision is not just about aesthetics but also about functionality, customer satisfaction, and brand image.

Accurate counting is a shared advantage between napkin tissue packing machines and facial tissue lines. Counting mechanisms, often equipped with photoelectric sensors and PLC control systems, ensure that each tissue box contains the exact number of sheets promised. This eliminates discrepancies that could harm brand credibility.

In the facial tissue line, the integration of automated counting systems reduces the chance of overpacking or underpacking, thereby lowering material waste and ensuring consumer satisfaction. Similar to napkin packing equipment, the emphasis on counting precision highlights the role of technology in maintaining consistency and compliance with industry standards.

Hygiene is a top priority in tissue production, whether for napkins or facial tissues. The napkin tissue packing machine ensures contamination-free packaging by sealing tissues in protective film. Similarly, the facial tissue production line emphasizes hygienic handling through contactless automation and secure boxing systems.

By minimizing direct human contact, the line reduces risks of contamination, ensuring tissues remain clean and safe for consumers. Furthermore, advanced sealing technology preserves product freshness by protecting against dust and moisture. Just like with napkin packaging equipment, hygienic design in facial tissue production enhances consumer confidence and meets health regulations.

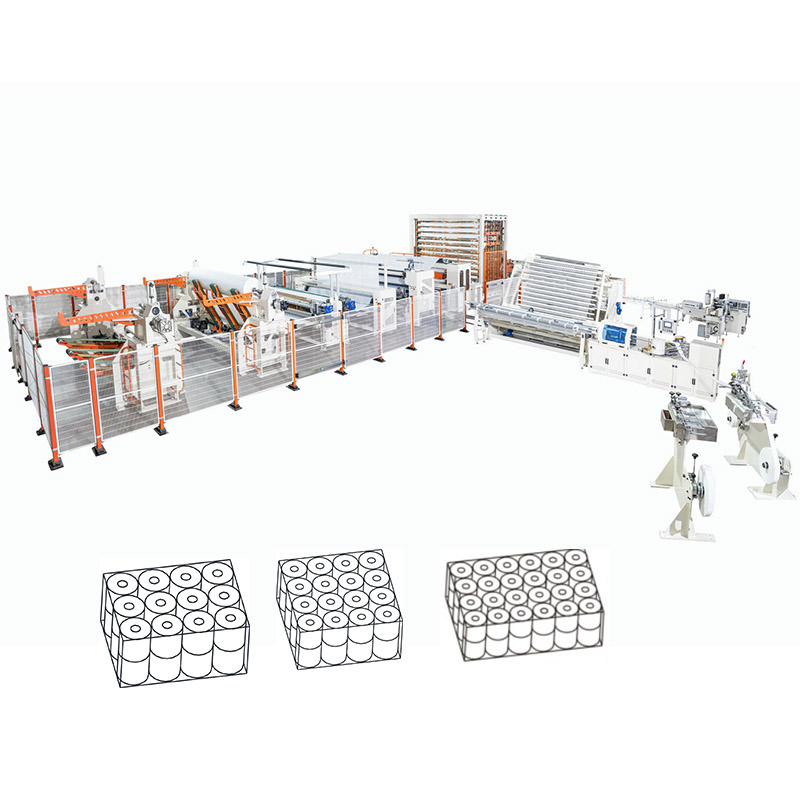

Production speed is a key factor in meeting rising consumer demand. Napkin tissue packing machines are designed for rapid packaging, and the facial tissue production line takes speed to the next level by handling continuous processes without interruption. High-speed cutting, folding, and boxing systems enable output of thousands of tissue boxes daily.

This efficiency reduces production cycles and lowers operating costs per unit. At the same time, advanced monitoring systems ensure that speed does not compromise product quality. By comparing with napkin packing machines, it becomes evident that efficiency in both cases is about striking the right balance between speed and precision.

Versatility is another shared strength between napkin tissue packing machines and facial tissue lines. While napkin machines can handle different fold types and pack sizes, facial tissue production lines are designed to adapt to various tissue sizes, box styles, and branding requirements. This flexibility allows manufacturers to cater to different markets and consumer preferences.

Whether producing standard facial tissue boxes for households or compact travel packs, the line can be adjusted to meet diverse demands. Just like napkin packaging machines, versatility in facial tissue lines ensures that manufacturers remain competitive by offering multiple product variations without investing in entirely separate systems.

The facial tissue production line is an advanced, automated solution that delivers precision, hygiene, speed, and versatility in producing high-quality facial tissues. By examining parallels with the napkin tissue packing machine, it becomes clear that innovations such as automation, accurate counting, hygienic packaging, and production efficiency are central to modern tissue manufacturing.

For manufacturers, these advantages translate into reduced costs, improved consumer satisfaction, and enhanced competitiveness in an increasingly hygiene-conscious market. As technology continues to evolve, both facial tissue lines and napkin tissue packing machines will embrace smarter automation, energy efficiency, and eco-friendly materials, driving the tissue industry toward a more sustainable and productive future.