Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2026-02-04

From Pulp to Profit: Your Ultimate Guide to Starting a Tissue Paper Business

Let’s face it: tissue paper is one of the few truly "recession-proof" products on the planet. Whether it’s a high-end restaurant, a busy hospital, or just a standard household, the demand for facial tissues, napkins, and toilet rolls is universal, constant, and—dare we say—unstoppable.

If you’ve been hunting for a manufacturing venture with massive market potential and steady scaling opportunities, you’ve found it. Here is your step-by-step roadmap to launching a high-output tissue paper manufacturing plant.

You can’t be everything to everyone on day one. Your raw material—the Jumbo Roll (sourced from wood pulp or recycled paper)—is a blank canvas. Decide which masterpiece you're creating first:

Facial Tissues: Premium margins; focus on that "cloud-like" softness.

Toilet Paper: The ultimate volume play; consistent, high-frequency demand.

Kitchen Towels: A booming market as households ditch cloth for hygiene.

Table Napkins: Your bread and butter for the F&B and hospitality sectors.

Pro Tip: Look at your local stores. What’s flying off the shelves fastest? Start there to ensure immediate cash flow.

Manufacturing isn't just about "set it and forget it." To maintain machine precision and top-tier ply quality, you need a brain trust.

Our Support: Already have a team? We offer free online guidance to keep your gears turning.

On-Site Training: Starting from scratch? We’ll send our specialists to your factory to install the machinery and transform your recruits into expert operators.

In manufacturing, location isn't just about the view—it's about the power.

Stable Energy: Frequent outages don't just stop production; they can damage sensitive machinery.

The Footprint: You need a layout that flows. Think: Raw Material Storage → Production Line → Finished Goods Warehouse → Logistics Bay.

Easy Access: If a heavy truck can't turn around in your driveway, you've got a problem.

Don’t launch on a "hunch." A profitable business is built on a deep dive into:

Competitor Pricing: Where can you undercut or offer better value?

Licensing: Get your environmental and business permits in order early.

Operational Costs: Factor in the "hidden" costs like waste management and electricity peaks.

The size of your factory dictates your capital strategy:

Small Scale: Often achievable through personal savings or private "angel" partners.

Industrial Scale: Requires a rock-solid business plan. If you want a bank or VC to write a check, you need clear ROI projections and a bulletproof growth strategy.

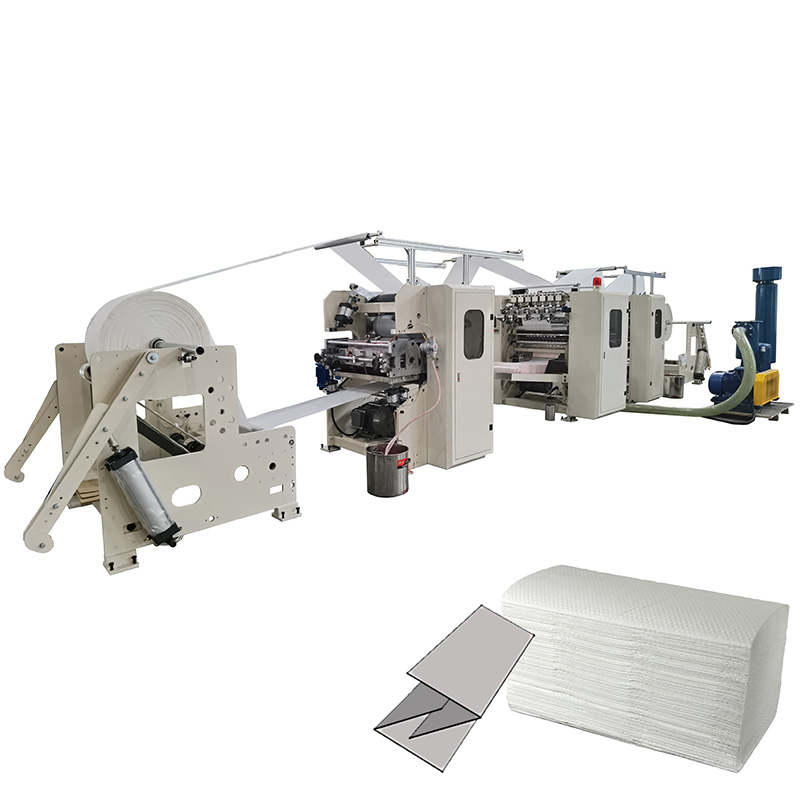

Your equipment is your most important employee. Don't bargain-hunt for the heart of your business. High-quality machinery (built to international standards) pays for itself via:

Maximum Efficiency: More "logs" per minute = lower cost per unit.

Zero-Waste Goals: Precision cutting means less of your expensive raw material ends up on the floor.

Durability: Less downtime, more uptime, more profit.

You don’t need an army, you need a balanced squad:

Skilled Operators: The "precision pilots" who manage the converting machines.

General Labor: The muscle for heavy lifting, feeding the line, and bulk packaging.

A great product is invisible without marketing.

Hire a Specialist: Get someone who already has the "rolodex" of local wholesalers and retailers.

Focus on Branding: In the tissue world, we do judge a book by its cover. High-quality packaging design often drives that crucial first purchase.

Building a factory is a complex puzzle, but you don't have to solve it alone. As leading manufacturers of tissue paper machinery, we don’t just sell equipment—we build partnerships. Our machines are world-renowned for their reliability, complying with the highest international standards.

Ready to turn paper into profit?

Please feel free to contact us for a customized machinery quote and let’s get your production line running!