Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2026-02-05

For tissue paper manufacturers aiming to balance productivity, cost control, and product quality, the right rewinding equipment is non-negotiable. With 10 years of engineering expertise in tissue processing machinery, our factory has designed a fully automated tissue paper rewinder that delivers precision, reliability, and scalability—tailored to meet the demands of global markets including Africa, South America, the Middle East, and Europe.

Our rewinder is engineered to solve pain points in tissue manufacturing, with features that prioritize efficiency and waste reduction:

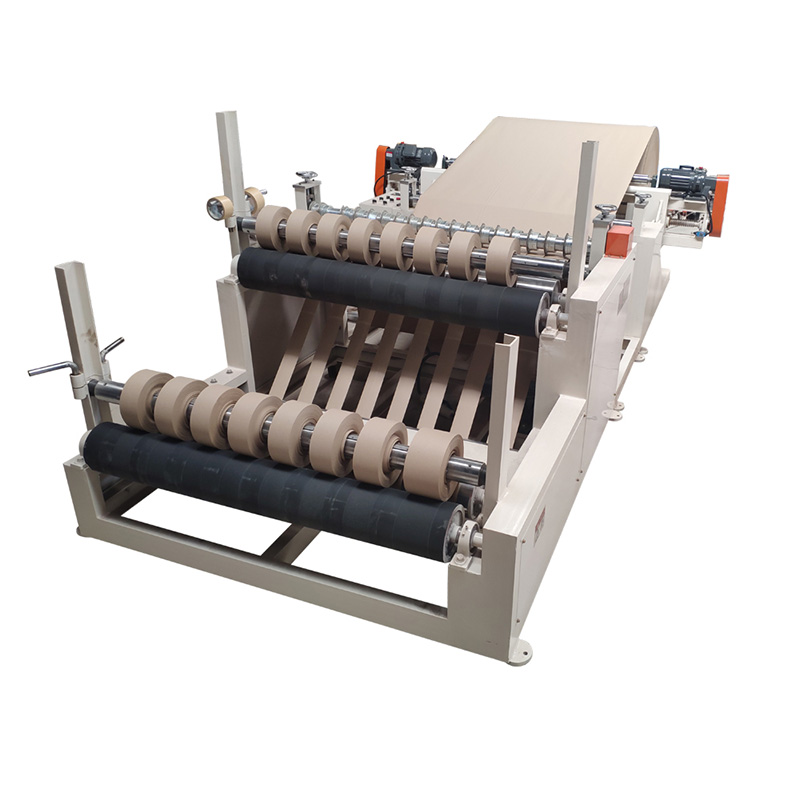

1.All-in-One Automation: Automates core feeding, log pushing, edge trimming, glue spraying, and sealing in a single synchronous cycle. By leaving only 10-18mm of tail material for re-rewinding, it minimizes shortcut waste and lowers operational costs.

2.Smart PLC Control: Powered by an internationally advanced PLC system with a user-friendly HMI, it enables intuitive parameter adjustment, real-time fault diagnostics, and data monitoring—all accessible via a touch screen for seamless operation.

3.Precision Engineering: Equipped with 4 high-precision spiral knives for low-noise, clean perforations, paired with a gearbox that ensures stable torque and a wider processing range. The 3 horizontal back stands and pneumatic loading system, with independently adjustable jumbo roll positions, accommodate diverse production needs.

4.Superior Embossing & Safety: The point-to-point embossing rollers create soft, clear patterns for a premium finish, while jogging switches simplify paper threading—making operation safer and more efficient.

As a CE-certified manufacturer, our equipment meets international safety and quality standards—critical for markets in Europe, the Middle East, and beyond. We’ve spent a decade refining our machinery to thrive in the unique operational environments of Africa and South America, ensuring durability, low maintenance, and adaptability to local raw material conditions.

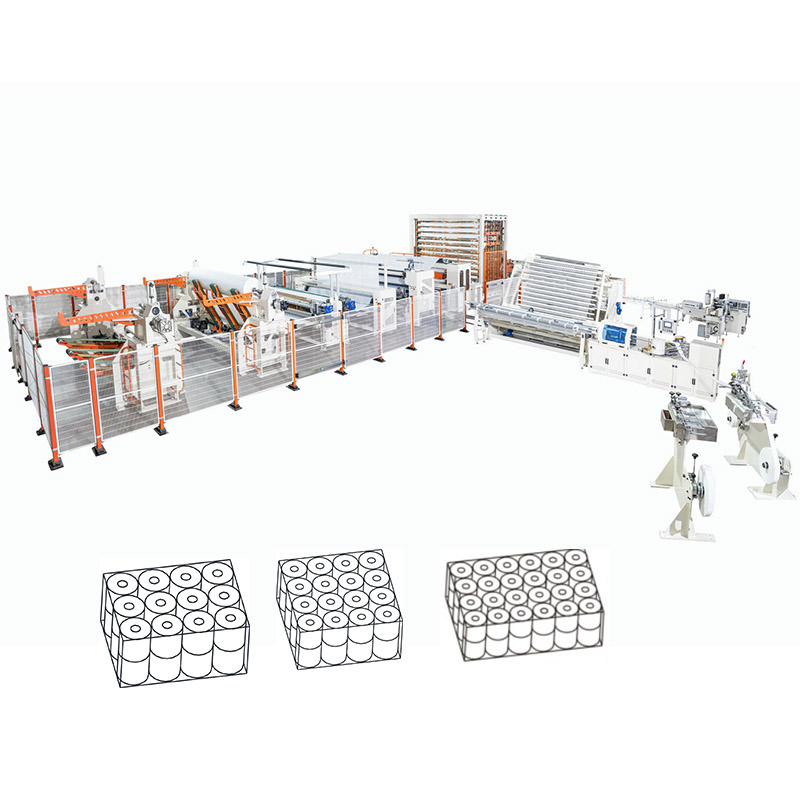

Whether you’re scaling a small production line or building a full turnkey tissue manufacturing facility, our rewinder integrates seamlessly with complementary machines (including tissue cutters and packaging systems) to create a cohesive, high-throughput workflow.

Let’s Connect

If you’re ready to upgrade your tissue production efficiency, reduce waste, and deliver consistent quality to your customers, our team is here to help. Message us directly to discuss custom configurations, request a detailed quote, or schedule a virtual demo of our rewinder in action.