Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2026-02-09

In 2026, the market for tissue paper production has evolved significantly. Driven by a global shift toward hygiene and sustainable packaging, the technology and cost of tissue paper machines have shifted to reflect modern efficiency standards.

Below is an updated and refined guide to the current costs, benefits, and purchasing factors for tissue paper machinery.

|

Machine Category |

Estimated Price (USD) |

Best For |

|

Manual / Entry-Level |

$3,000 – $10,000 |

Home-based startups or small local workshops. |

|

Semi-Automatic |

$12,000 – $45,000 |

Small to medium enterprises (SMEs) balancing cost and speed. |

|

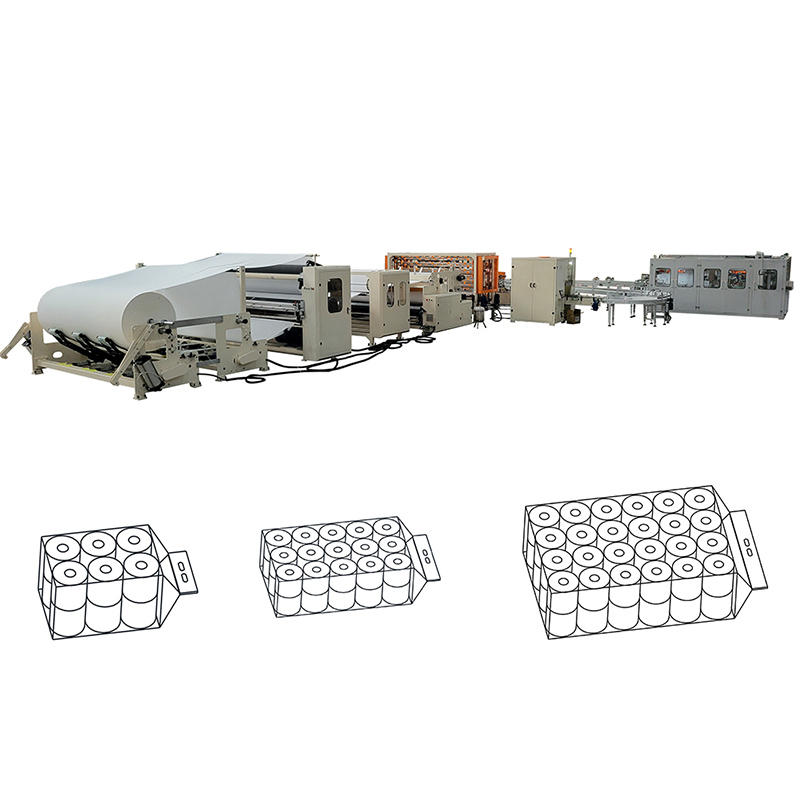

Fully Automated Line |

$60,000 – $500,000+ |

Large-scale commercial production with minimal labor. |

|

Industrial Paper Mill |

$1.5M – $10M+ |

Complete turnkey plants (15–100+ Tons Per Day). |

Investing in a dedicated tissue machine offers several competitive advantages in today's market:

Production Velocity: Modern machines can produce thousands of sheets per hour, vastly outperforming manual folding or cutting.

Consistency & Quality: Advanced sensors and PLC (Programmable Logic Controller) systems ensure every roll or sheet meets exact specifications for thickness, embossing, and size.

Operational Efficiency: 2026 models are designed with energy-saving technology, which can reduce utility costs by up to 25% compared to older versions.

Waste Reduction: Automated splicing and precision cutting minimize raw material waste, protecting your profit margins.

Purchasing a machine is a long-term commitment. To ensure a high return on investment (ROI), consider these factors:

Match the machine's capacity to your sales forecast. Over-investing in a high-capacity machine you can't fill leads to idle costs, while under-investing results in missed orders.

With the 2026 focus on "Green Manufacturing," look for machines that can handle recycled pulp or alternative fibers (like bamboo). Features like double embossing and automatic packaging are also becoming standard requirements for retail-grade products.

The "hidden cost" of any machine is downtime.

Check for the availability of spare parts in your region.

Confirm if the manufacturer offers remote diagnostics or on-site technical support.

Factor in an annual maintenance budget (typically 15-20% of operational expenses).

Tissue paper remains an evergreen daily necessity, making production a stable business venture. Whether you are starting a boutique napkin brand or a large-scale toilet tissue facility, the right machinery is the backbone of your success.