![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XY-TQ-A-C

Model:

XY-TQ-A-C

![]() Power:

18KW 380V 50HZ 3Phase (depends on the jumbo roll width)

Power:

18KW 380V 50HZ 3Phase (depends on the jumbo roll width)

![]() Application:

Small toilet paper roll production line

Application:

Small toilet paper roll production line

![]() Weight:

4 tons ( Depends on the model)

Weight:

4 tons ( Depends on the model)

![]() Output:

small toilet paper roll

Output:

small toilet paper roll

![]() Packaging Dimension:

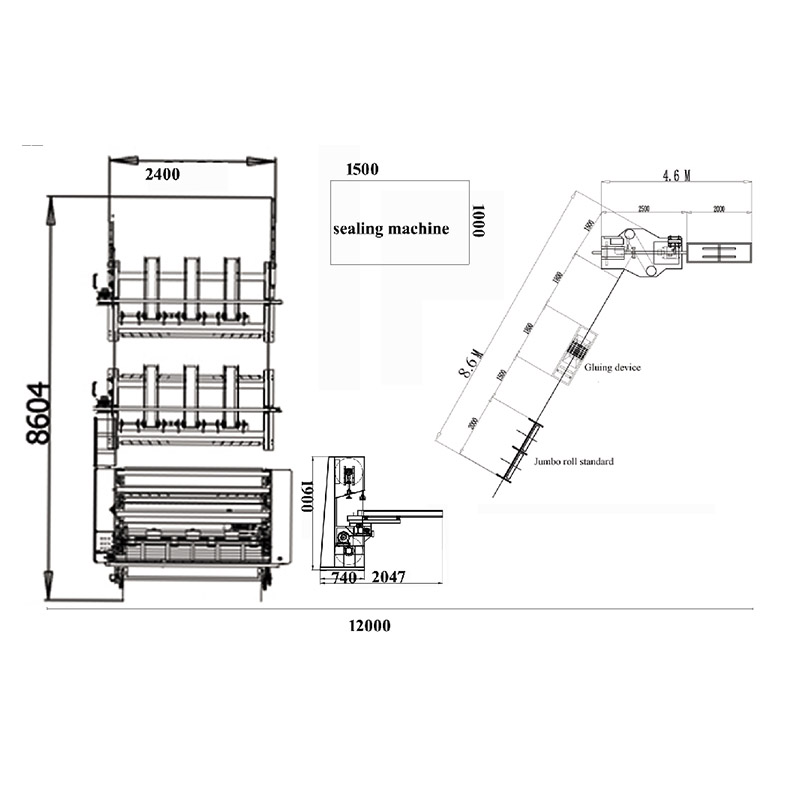

12000*8640*2200mm

Packaging Dimension:

12000*8640*2200mm

![]() Machine Size:

Machine Size:

![]() Certification:

CE, ISO

Certification:

CE, ISO

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine

The XY-TQ-B is an advanced perforating and rewinding machine designed to transform jumbo roll into toilet paper products with precision and efficiency. Engineered for paper manufacturers and processing plants, this equipment delivers consistently neat, well-ordered outputs with uniform tension across all product dimensions.

Key Features:

Compact & Efficient: Space-saving design with low energy consumption

High-Speed Production: Operates at 200-230 m/min maximum speed

Versatile Processing: Handles jumbo rolls (1,200-3,000mm width) and customizable product sizes

Stable Operation: User-friendly interface with robust mechanical structure

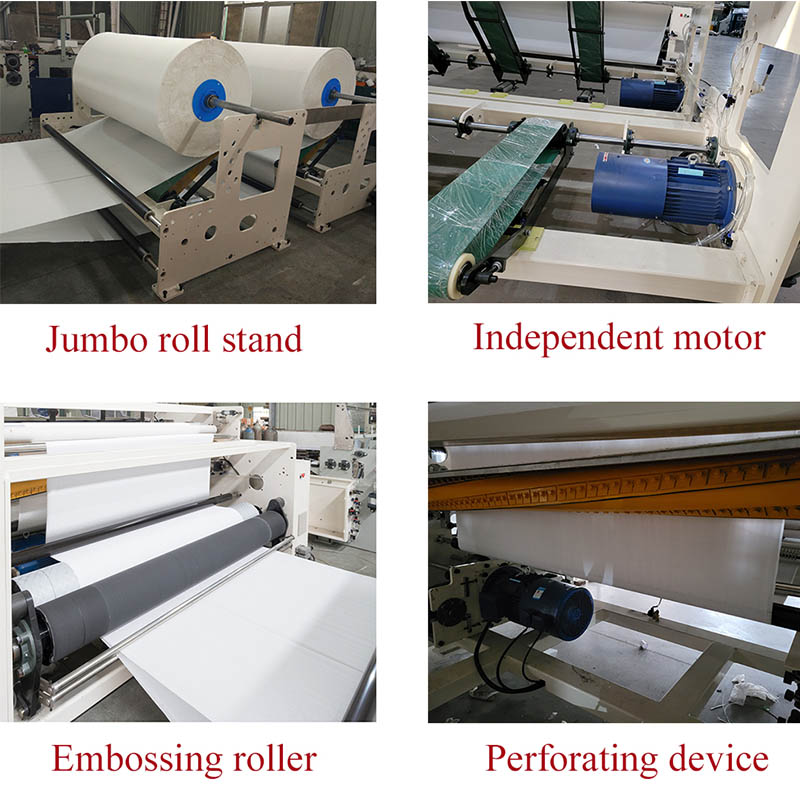

Technical Composition:

Raw material stand

Paper conveying unit

Embossing unit

Perforating unit

Rewinding unit

Electrical control system

Cutting system

Production Workflow:

Unreeling → 2. Embossing → 3. Perforating → 4. Rewinding → 5. Tail-gluing → 6. Edge trimming

Ideal for modern paper production facilities, this system combines industrial durability with intelligent automation to meet diverse manufacturing requirements.

2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine

This specialized cutting machine is designed as a complementary system for rewinding and perforating toilet paper production lines. Its primary function is to precisely convert large rewound toilet paper rolls into standardized smaller rolls, catering to both toilet paper and kitchen towel manufacturing.

Key Features:

Precision Cutting: Converts jumbo rolls into various standard sizes with clean, uniform cuts

Compact & Efficient: Space-saving design with stable, low-vibration operation

User-Friendly: Intuitive controls for quick adjustments and easy maintenance

3. XY-AI-398-B Plastic Bag Sealing and Packing Machine

Key Features:

Dual digital temperature control prevents damage to:

✓ Heating elements

✓ Protection tapes

✓ Air cylinders

Versatile Performance

1. 490mm operating width accommodates diverse bag sizes

2. Adaptive temperature control for materials of varying thicknesses

3. Room-temperature-independent operation maintains stability in any environment

4. uitive controls for quick adjustments and easy maintenance

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine

Technical data:

1. Production speed: 200-230m /min

2. 1850mm width of jumbo roll

20mm thickness of wall board of machine

3. Diameter of finished toilet paper: 90-280mm

4. Diameter of finished toilet paper inner core: 38-76mm

5. Perforation distance: 4 anvil Blades(90-150mm)

6. Power:18kw (380V 50Hz 3Phase)

7. Max. diameter of jumbo roll paper : 1200mm

8. Diameter of jumbo roll paper inner core: 76.2mm

9. Overall size(L*W*H): 6500*2800*2100mm

10. Weight : About 4T

11. Two sets paper standers (Individual motor to control the tension) and one sets of steel to rubber embossing roller.

12. Individual motor for each jumbo roll stander, PLC control the tension of paper

13. HS code: 8441809000

2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine

Main technology parameter:

1.Power : 2.2KW (380V 50Hz three phase)

2.Production speed : 30-40 rolls /min

3. Maximum diameter of cutting:150mm

4.Overall size: 1600x600x1800 mm (LxW xH)

5.Weight: 400KG

6.HS code: 8441100000

3. XY-AI-398-B Plastic Bag Sealing and Packing Machine

Technical data:

1.Speed: 10-20 bag/minute

2.Power: 1.5 KW (220V 50Hz single phase)

3.Overall size:900x600x1000 mm (LxW xH)

4.Weight: 80KG

5. Sealing width:47 cm

6.HS code: 8422309090

The XY-TQ-A-C Start business small toilet paper roll machine production line is a fully integrated manufacturing system designed for start business production of small toilet tissue rolls. This cutting-edge production line combines three easy operate machines to deliver product quality:

which composed :

1. XY-TQ-B High Speed Toilet Paper Rewinding Machine

2. XY-AI -300 Semi automatic Toilet Paper Cutting Machine

3. XY-AI-398-B Plastic Bag Sealing and Packing Machine

Production Process:

Unwinding: Large parent rolls are loaded onto the unwinding station with tension control

Embossing: The XY-TQ-B machine creates consistent dot patterns for enhanced texture

Rewinding: Multi-stage rewinding ensures uniform density and core alignment

Tail Gluing: Food-grade adhesive application for secure roll formation

Edge Trimming: Laser-guided trimming for perfect roll edges

Cutting: Precision cutting to customer-specified lengths

Packing: Automated bagging with quality inspection before sealing

1. XY-TQ-B Automatic lamination toilet paper making machine Feature and Function 1. Automatic Core Feeding Rewinding System Features automated log pusher post-rew...

This production line consists of : 1. XY-TQ-B A utomatic color printing m axi ki tchen towel roll rewinding machine Feature and Function 1. Aut...

Model cutting and sealing machine temperature shrink machine Power source 220V 50Hz/60Hz 380V 50/60Hz Rated Power 1.35KW ...

The toilet paper machine features smooth operation with minimal downtime.Jelena 2025-09-02

This toilet paper machine has revolutionized our production line! The precision is unmatched, and the automation features have reduced our labor costs by 30%.2025-11-04

This machine is a game-changer! The toilet paper rolls it produces are soft yet strong, just like premium brands. Worth every penny!"2026-01-26

This kitchen towel machine exceeded expectations! good effect of kitchen towel made a huge difference, and the support team was helpful throughout the process2025-11-04