Author:XINYUN Tissue Paper MachineFROM:Tissue Machine Manufacturer TIME:2026-01-16

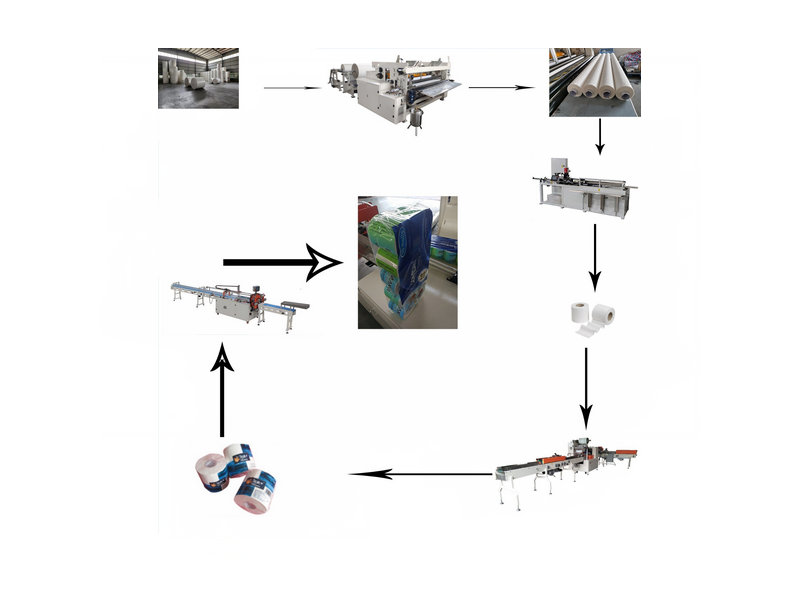

In our daily lives, toilet paper is an indispensable item. But have you ever wondered how those massive jumbo rolls of paper are transformed into the familiar, convenient toilet paper rolls we use every day? The process is a fascinating blend of engineering and automation, carried out by specialized toilet paper machines. Let's delve into the step - by - step journey of this transformation.

The process kicks off with the unwinding of the jumbo roll. These jumbo rolls are extremely large, often weighing several hundred kilograms and containing a vast amount of paper. The toilet paper machine is equipped with a mechanism that carefully unwinds the paper from the roll at a controlled speed. This is crucial as it ensures that the paper is fed smoothly into the subsequent stages without any tears or jams. The unwinding speed can be adjusted according to the requirements of the production line, allowing for efficient processing.

Many toilet paper products feature decorative patterns or textures. This is achieved through the embossing process. After the paper is unwound, it passes through a set of embossing rollers. These rollers have intricate designs engraved on their surfaces. As the paper moves between them, the pressure exerted by the rollers imprints the patterns onto the paper. Embossing not only enhances the aesthetic appeal of the toilet paper but also improves its functionality by increasing its thickness and softness in certain areas, providing a more comfortable user experience.

Perforation is a key step in making toilet paper user - friendly. The paper, whether embossed or not, then goes through a perforating unit. This unit consists of sharp blades or rollers with small teeth that create evenly spaced perforations across the width of the paper. These perforations allow users to easily tear off a specific number of sheets when needed. The spacing and strength of the perforations are carefully calibrated to ensure that the paper tears cleanly without leaving any ragged edges or causing excessive tearing.

Once the paper has been embossed and perforated, it's time for rewinding. The paper is guided onto a new core, which is typically made of cardboard. The rewinding process is carried out by a set of rollers that apply tension to the paper, ensuring that it is wound tightly and evenly onto the core. This creates a compact and stable roll of toilet paper. The speed of rewinding and the tension applied are precisely controlled to prevent the paper from becoming too loose or too tight on the roll.

After the paper is rewound onto the core, the long roll needs to be cut into individual, smaller rolls that are the standard size for consumer use. A cutting mechanism, often consisting of a rotating blade or a set of shears, slices the large roll at the appropriate intervals. The cutting process is synchronized with the rewinding process to ensure that each roll is cut accurately and consistently.

The final step in the transformation is packaging. The individual toilet paper rolls are then fed into a packaging machine. This machine can package the rolls in various ways, such as wrapping them in plastic film or placing them in cardboard boxes. The packaging is designed to protect the toilet paper during transportation and storage, as well as to make it attractive and convenient for consumers to purchase. Some packaging machines are also capable of adding labels, barcodes, and other information to the packages for identification and tracking purposes.

Throughout the entire process, automation plays a vital role. Modern toilet paper machines are highly automated, with computer - controlled systems monitoring and adjusting various parameters such as speed, tension, and cutting accuracy. This not only improves production efficiency but also ensures consistent product quality.

Quality control is also an integral part of the production process. Sensors are installed at different stages of the machine to detect any defects or irregularities in the paper, such as tears, uneven embossing, or incorrect perforations. If any issues are detected, the machine can automatically stop or make adjustments to correct the problem, minimizing waste and ensuring that only high - quality toilet paper reaches the market.

In conclusion, the conversion of jumbo rolls into finished toilet paper products is a complex yet well - orchestrated process. From unwinding and embossing to rewinding, cutting, and packaging, each step is carefully designed and executed to produce the soft, convenient, and high - quality toilet paper that we rely on every day. The next time you reach for a roll of toilet paper, you'll have a newfound appreciation for the sophisticated machinery and processes that went into making it.